Does the controller have a USB socket for external programs?

Serial comms through an RS232 port – ’80s control system here !

To offer any meaningful suggestions I need to know how the control is configured. A “basic” Fanuc control is just that – very basic ! But they offered a very large extra cost options selection and the options chosen can vary how the control functions considerably. The manuals do not help here, as they describe the operation of all the options available and may not be applicable to your particular machine if the option is not installed. There was a Fanuc “Descriptions” manual that detailed all the functions & showed what was standard in the basic control and what was optional. Options costs varied considerably, from around £10 for simple changes like display of a clock on the CRT or resettable parts counter (incremented by the M30 end of program code for keeping track of batch sizes) to many hundreds for memory increases – a basic configuration came with only 10 metres paper tape equivalent memory. Some options were just turning on software functions, but others required hardware changes – memory increases above a certain size required extra RAM & graphic simulation required a different display board, for example.

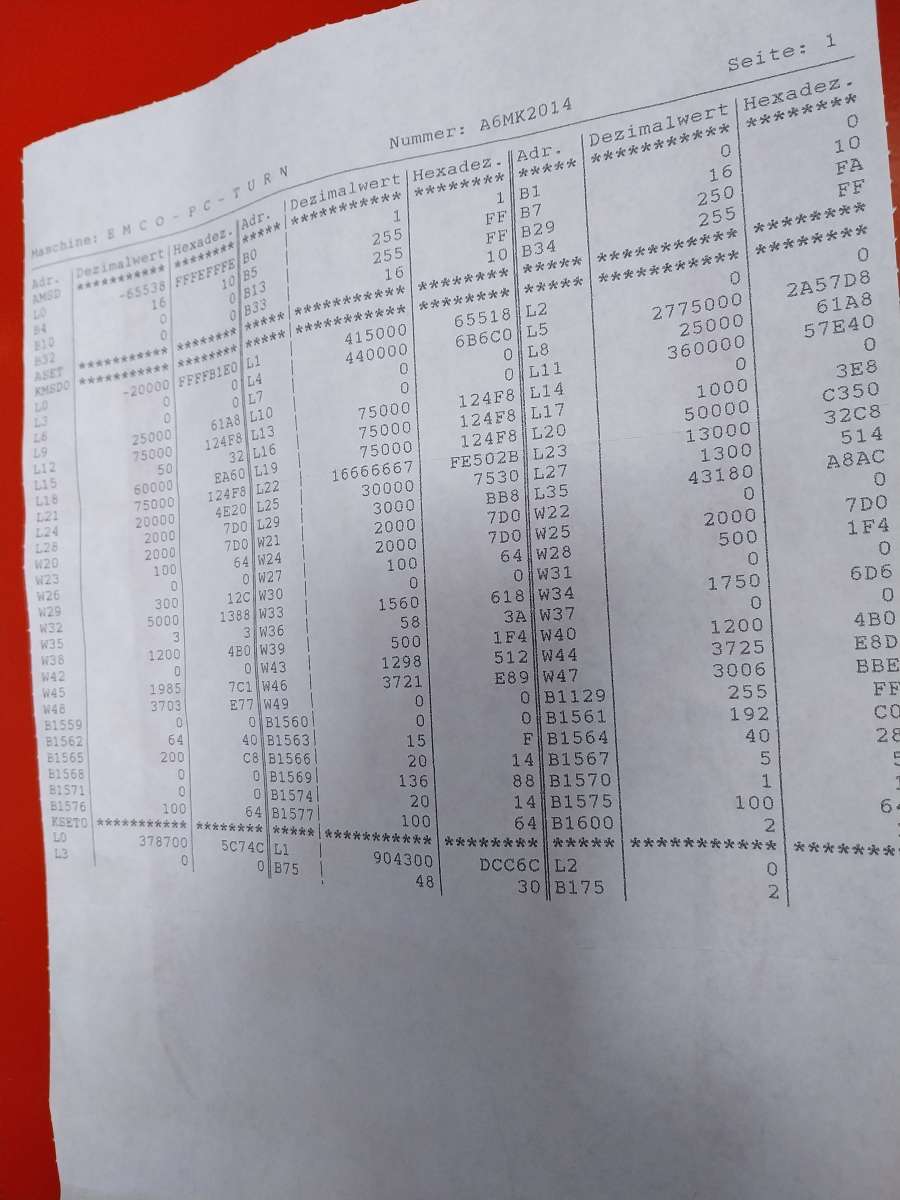

In your documentation there should be a Fanuc data sheet which gives the options installed at time of purchase & which would be updated by a Fanuc technician if options were subsequently purchased – option upgrades could only be installed via an on-site visit by a Fanuc tech & they would not proceed if the data sheet was not present. The data sheet is typically a flimsy 3 sheet fan-fold dot matrix printed multi part print out with a blue type (like a carbon copy). The first page has the control serial number, build date etc. then details of the part numbers and revisions of the boards used in the system. Next was details of pcb link or DIP switch settings, then a description (with part numbers) of the installed options . Last page was a listing of the option parameter settings – these are the 9000 series parameters, each being in 8 bit binary format. These parameters are not listed in the control documentation, being “secret” to Fanuc. Any subsequently purchased option upgardes were manuall written up on the data sheet by the Fanuc tech at time of installation.

The Emco documentation may also list the options that Emco selected as their “standard” supply – the company I used to work for always included several options that my then-MD felt were a basic requirement for a user friendly system.

Do you know when the memory backup batteries were last changed ? There should be a black battery box with a Fanuc logo on the side of the electrical cabinet holding 3 x alkaline D cells. Usuallly a “BAT” message comes up on the bottom of the display (along with an expanded message on the “Alarms” page) when the batteries are depleted, but I always changed them annually before the Xmas shutdown at work, as batteries on the point of being depleted would often dip too low if left for a couple of weeks in low temperatures, leading to loss of the battery retained data. Note that with these controls the batteries must only be replaced with the system powered up – there is no “Super Cap” or other temporary memory support to enable the batteries to be changed with power off. Pull the batteries with the power off and you will loose (as a miniumum) part programs, tool offsets and parameters – not the end of the world if you have backups, but a PITA non the less.

Nigel B.

Emgee.