FB2 users, how do you go about tramming the mill?

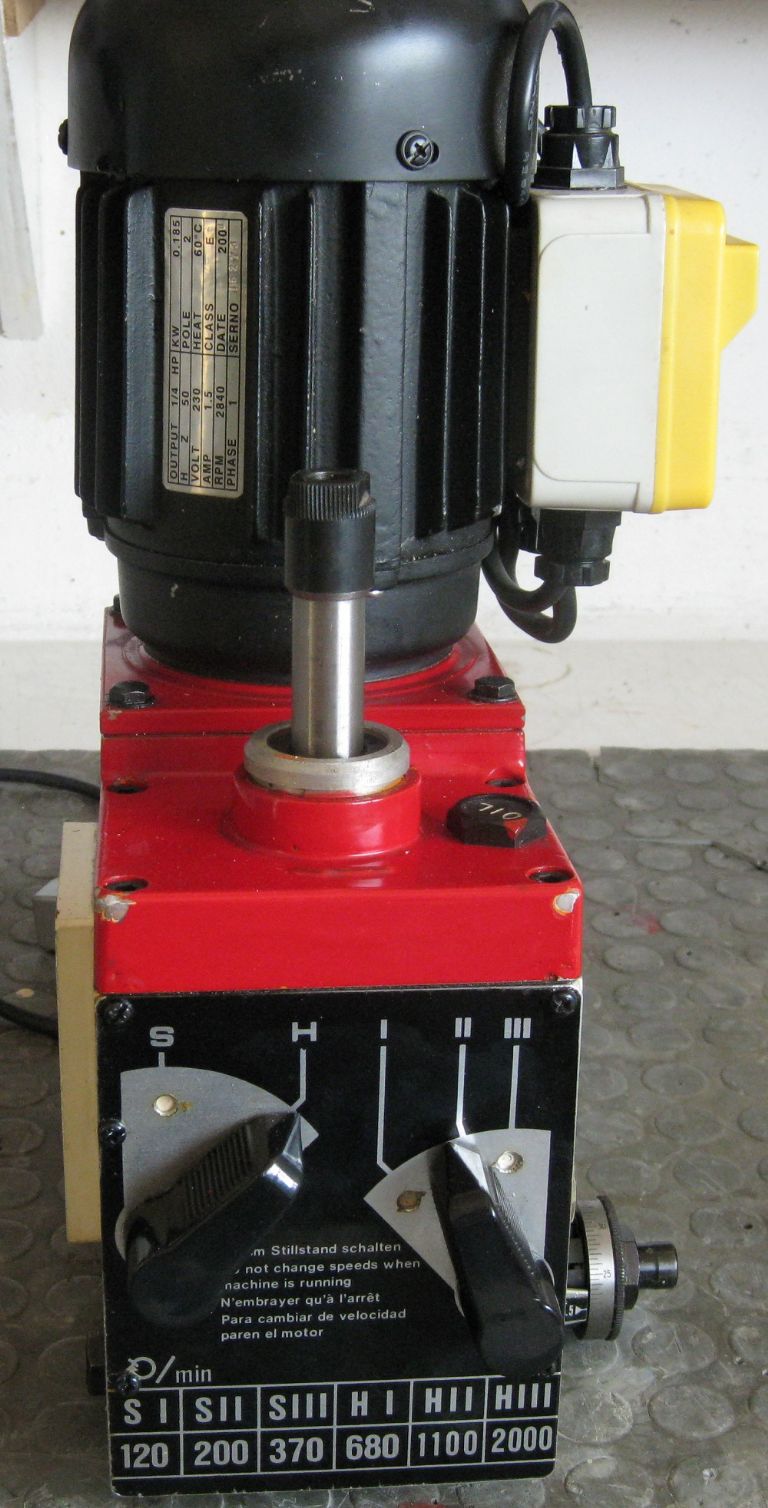

I need to do some rather delicate and accurate, deep , large diameter boring on the FB2, and need to tram the machine really well.

I have set the column perpendicular to the table – set up an accurate refence cylinder square (100mm diameter and 200mm tall) on the table with a DTI in the spindle. Then run the head up and down with the DTI rubbing the west side of the square and adjust the column left/right.

Then to repeat the process with the DTI on the South face of the cylinder square for forward/rearwards column tilt. But how best to adjust the forward/rearward tilt of the column? I did by means of paper thin spacers at top or bottom of the column support base but that is really fiddly. Is there another way?

As the head can tilt left and right, I then keep the complete head in fixed position, DTO on west side of the square, and using the quill feed, run the DTI up/down the square, and adjust the 2 tilt bolts while fiddling the head vertical.

Now, after doing all that, with the column pretty close to perpendicular north/south and east/west, and the head set properly vertical in east/west, I then put the usual DTI on the end of a long arm, in the spindle, and rotate the DTI over the table in a circle. Expecting a decent dial readout, I was rather disappointed…The DTI reads high (0.2mm..!) on the table surface closest to the operator, and zero on the table near the column. Left and right are equal, at around 0.08mm….

I spent most of the morning doing this, over and over….I rechecked – the column is perpendicular within 0.01mm over a 180mm height on the south and west sides of the square. I checked the square – rotating the square 90deg and 180deg shows the same 0.01mm deviation.

It would appear that the spindle head ( ie, the quill and head) has some 'nod' – is 'drooping' down and I don't see how to adjust this – not in the manuals, and not evident in the parts breakdown either.

Any advice will be most welcome!

Joe

Ian P.

Ian P.