The latest item to be made for the Compact 5 could quite easily be adapted for any type of lathe. It does warrant a listing under “Tool Height Setting Gauge” but to be honest I have forgotten how to start a new thread on this new forum.

Since George H Thomas designed his Tool centre height gauge this has served me well for the past 40 years. Since going to a smaller lathe its use has been a bit of a trial. The size of the C5 cross slide is one issue the other being my failing vision.

Something which made my life easier and which was in keeping with the C5 was needed. Talking it over with John Slater back in January / February started a flurry of activity on the drawing board. Along with a multitude of Patents from John on Lever Operated Indicators.

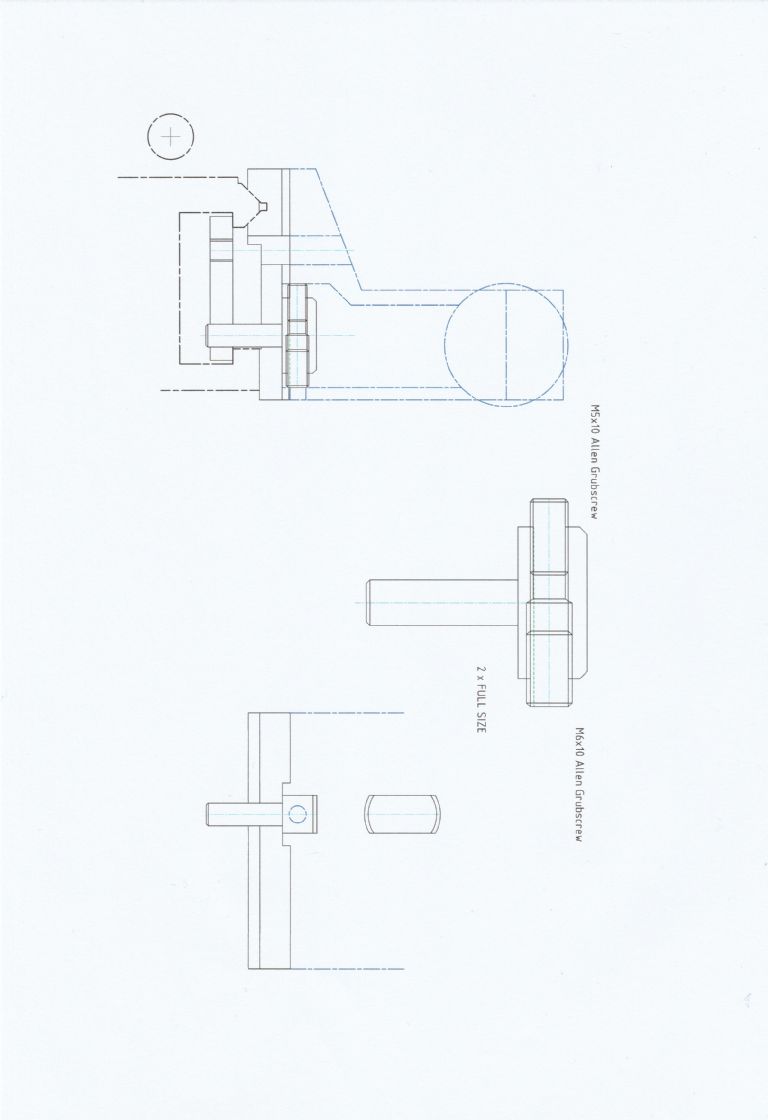

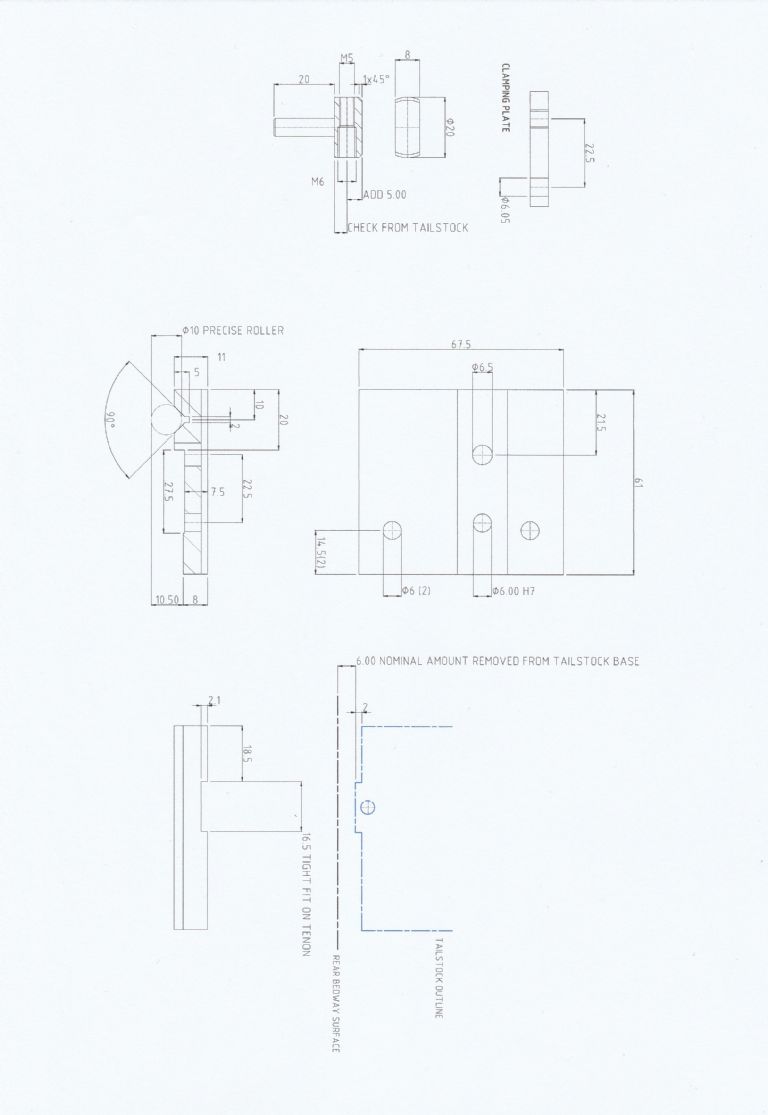

Things were really simplified when John suggested using conical bearings for the pivots. These come in the shape of Carbide Insert retaining screws and I have to thank Ketan and Ian at Arc Euro Trade for their help here.

The design here was up to issue 10 before any machining had started. However it does live up to my expectations and has already made setting tools easier. One of the earlier designs had a more vertical scale which was viewed through a magnifying lens, (piece of Perspex rod). However a wooden mock-up of this version made it too big for the C5 cross slide.

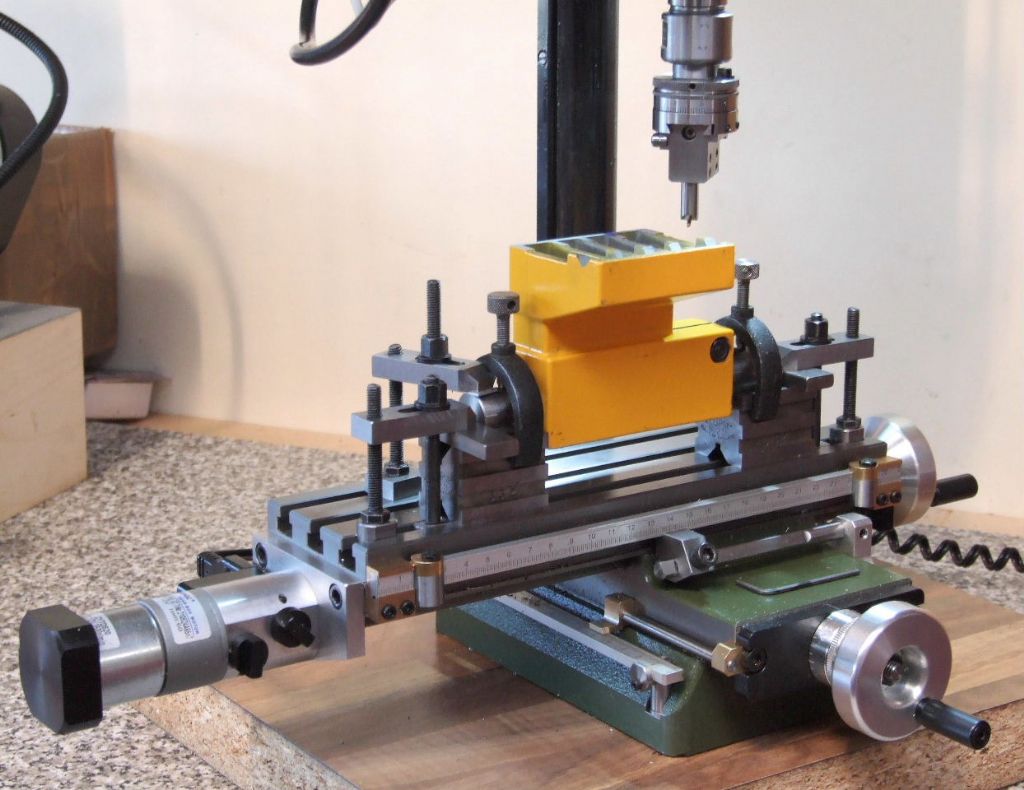

The Gauge is shown being used to set the “Half Pin” horizontal before actually setting the Gauge to Zero on this pin.

This second image shows a turning tool being set. The pointer is on Zero, but the camera says otherwise, (parallax).

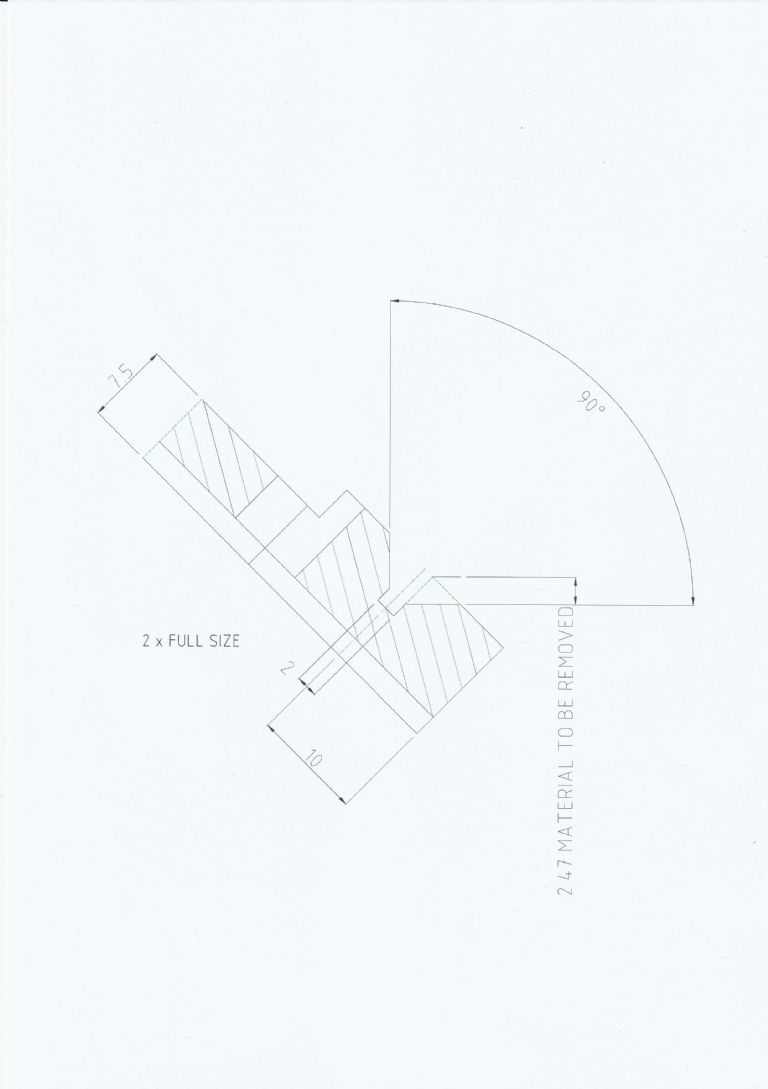

By turning the Gauge Probe through 180 degrees and Moving the Direction lever. Inverted or upside down boring bars can be set without any alteration to the original setting of the Gauge.

This view shows the Probe details.

While this image shows the Direction Lever.

The graduations on the scale represent 0.05 mm per division and the scale is a simple print out.

More later,

Regards

Gray,

Graham Meek.