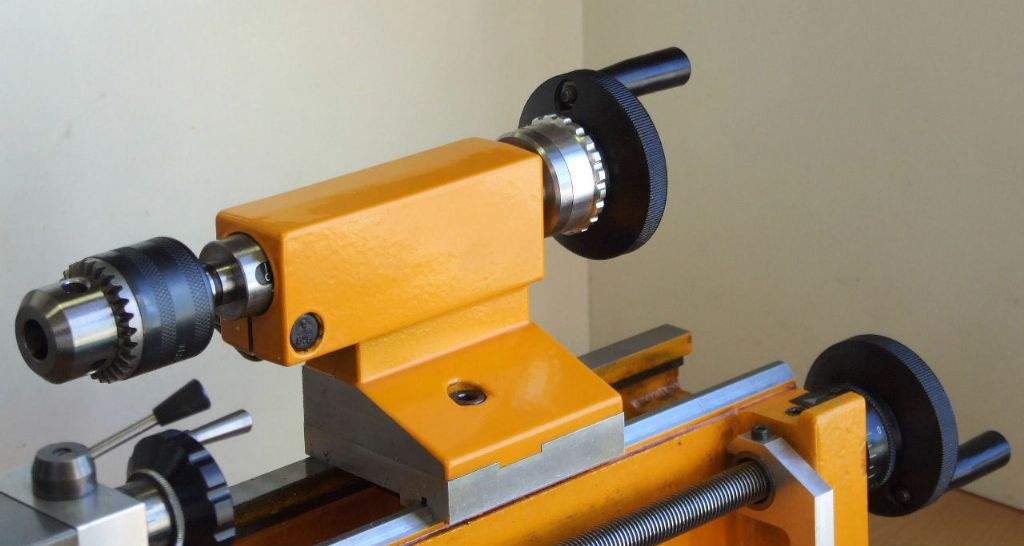

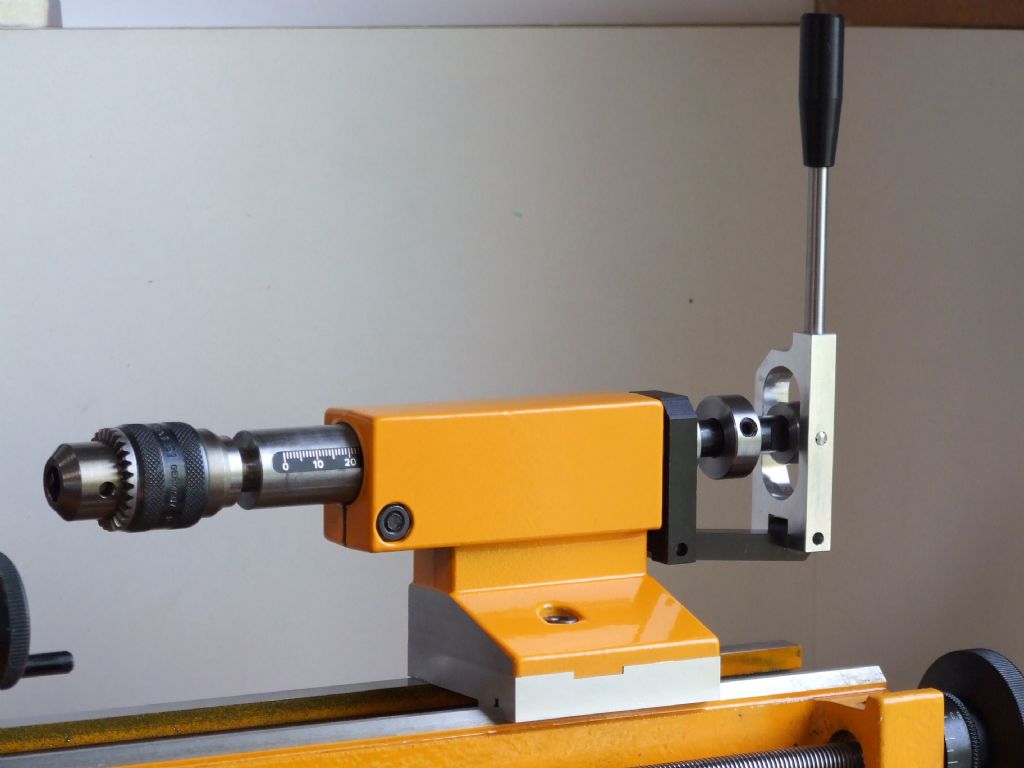

The next thing to tackle was the manufacture of a 22 mm diameter parallel mandrel. This was just a piece of BMS turned between centres. I chose to manufacture a mandrel rather than use a piece of say Silver Steel, because there would be no guarantee the Silver Steel would fit the tailstock bore.

While we in the UK work to the Hole Based system of Limits and Fits. On the Continent where this lathe was made they work to the Shaft Based system. While I know a piece of Silver Steel will go in a standard UK, H7 hole. What tolerance has been applied to the Austrian hole is anyone's guess.

Without the spare tailstock which I had adapted this operation could have been a problem with the Original tailstock. I would have got around it by using strategically placed pieces of paper, but it would have been very trying.

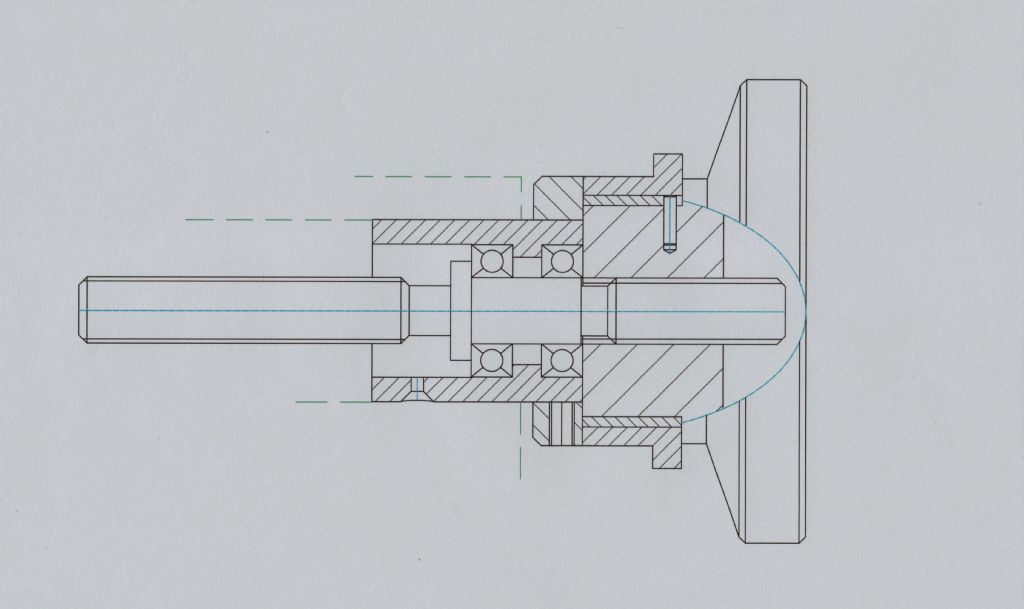

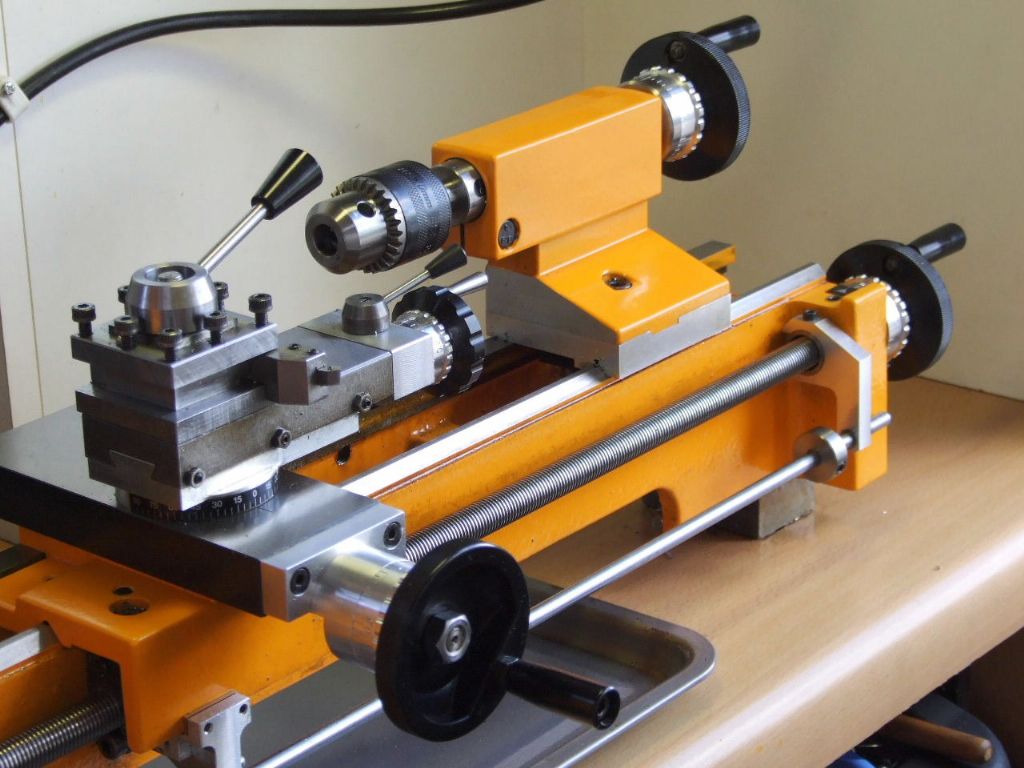

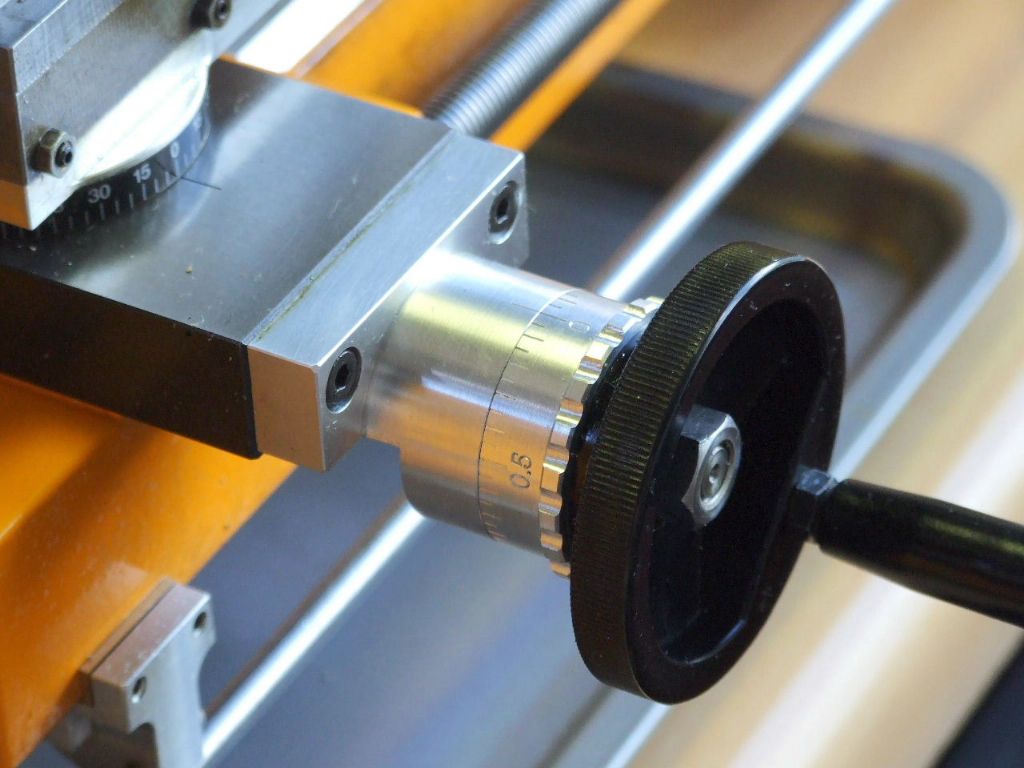

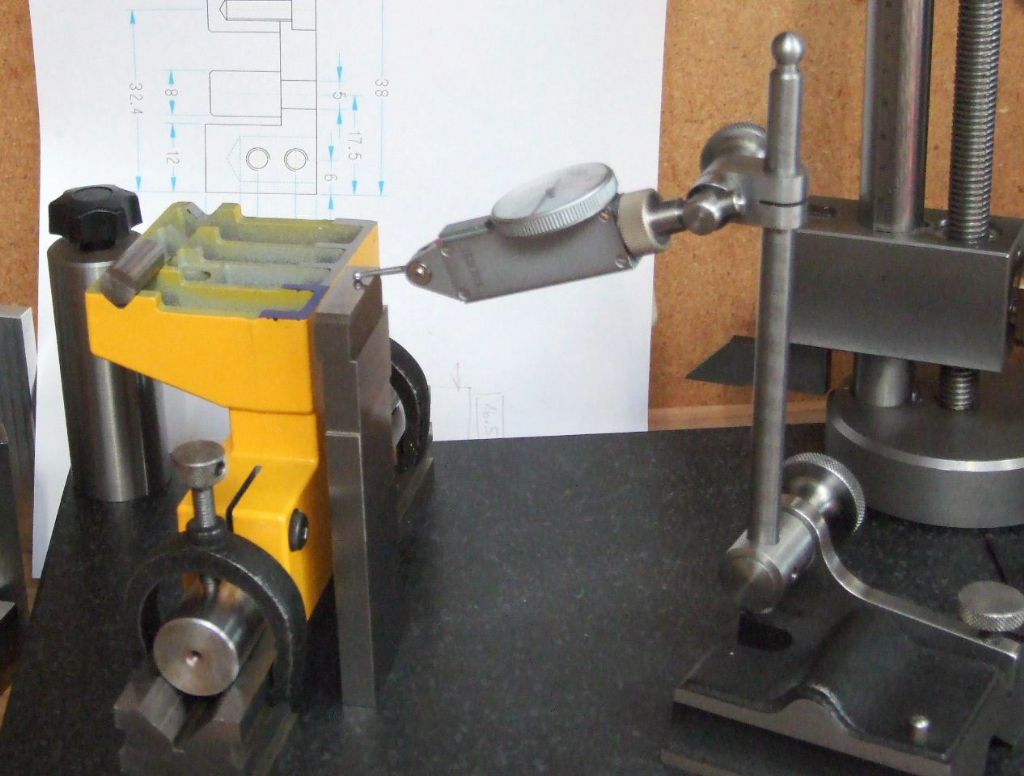

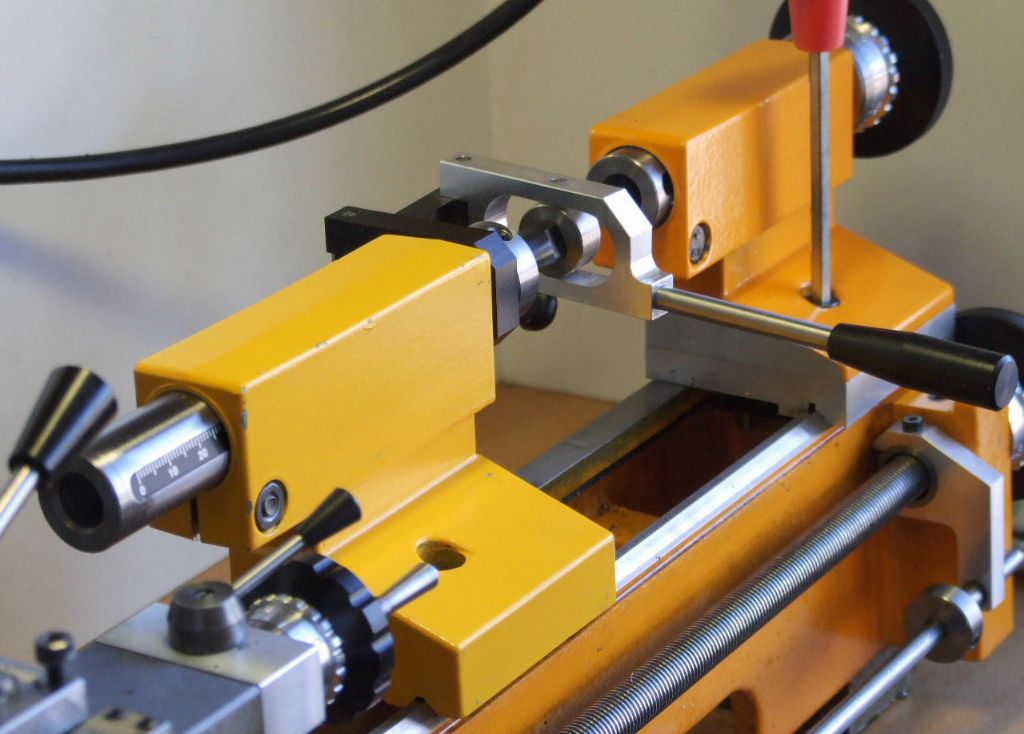

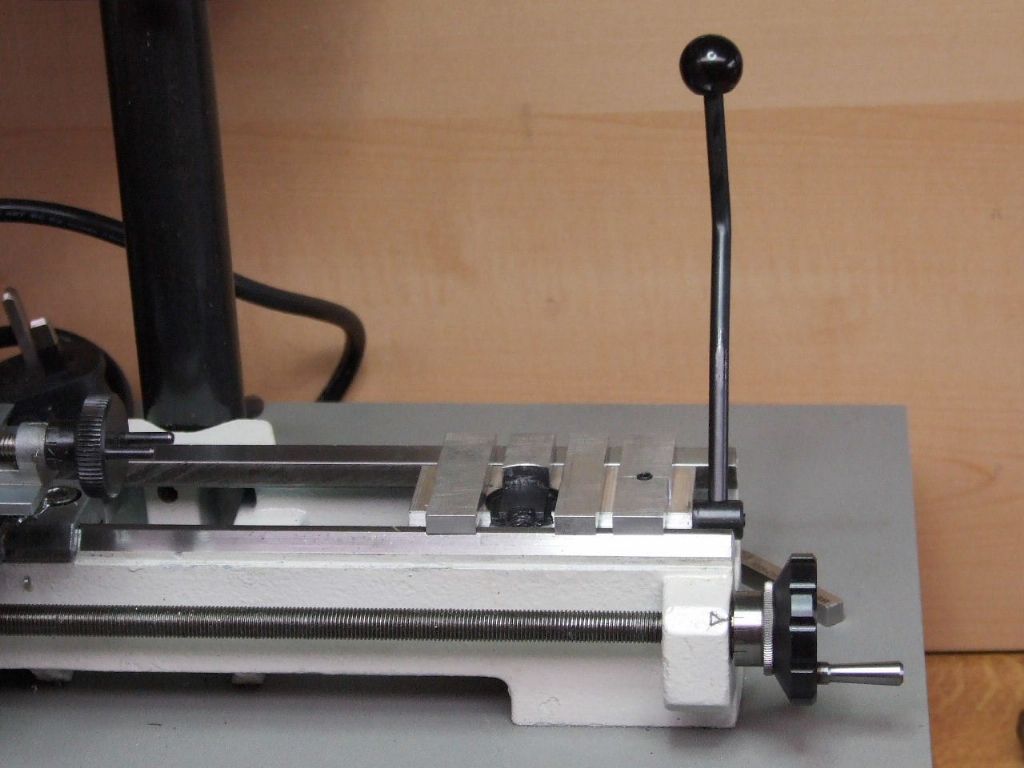

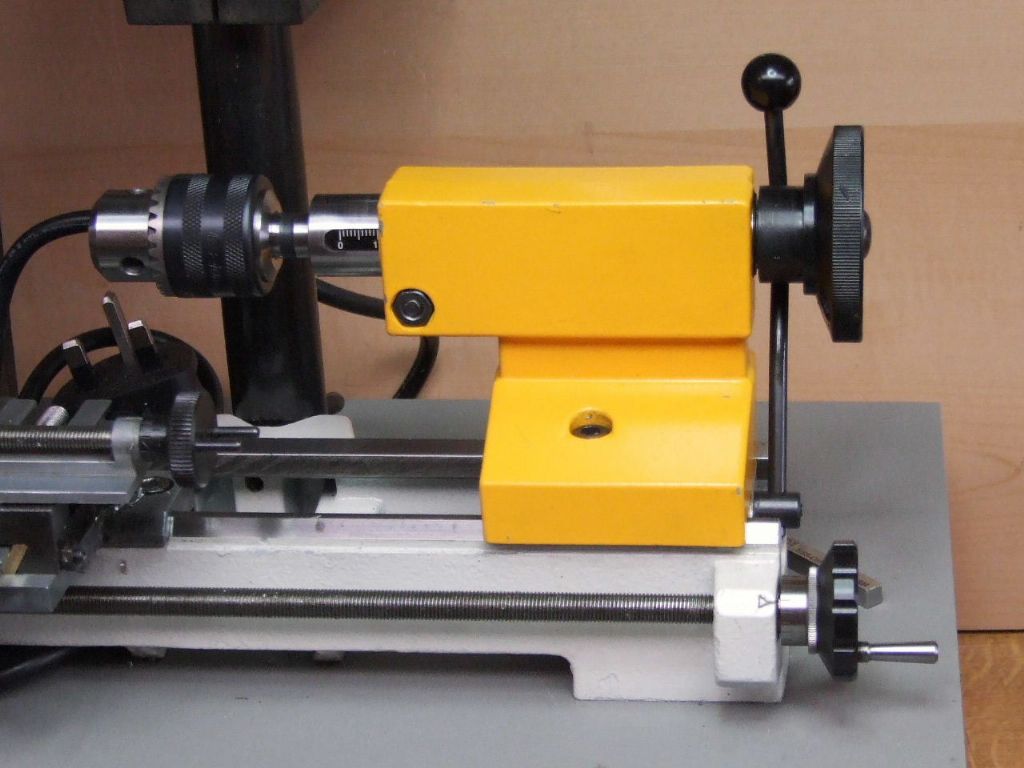

The Mandrel was made long enough to support the tailstock and rest in my matched pair of Vee blocks.

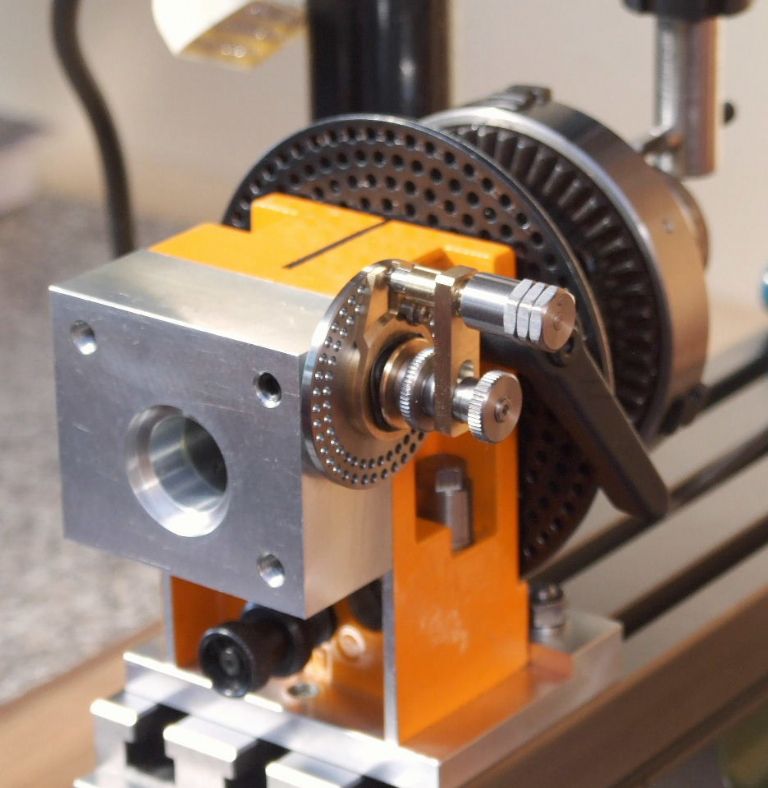

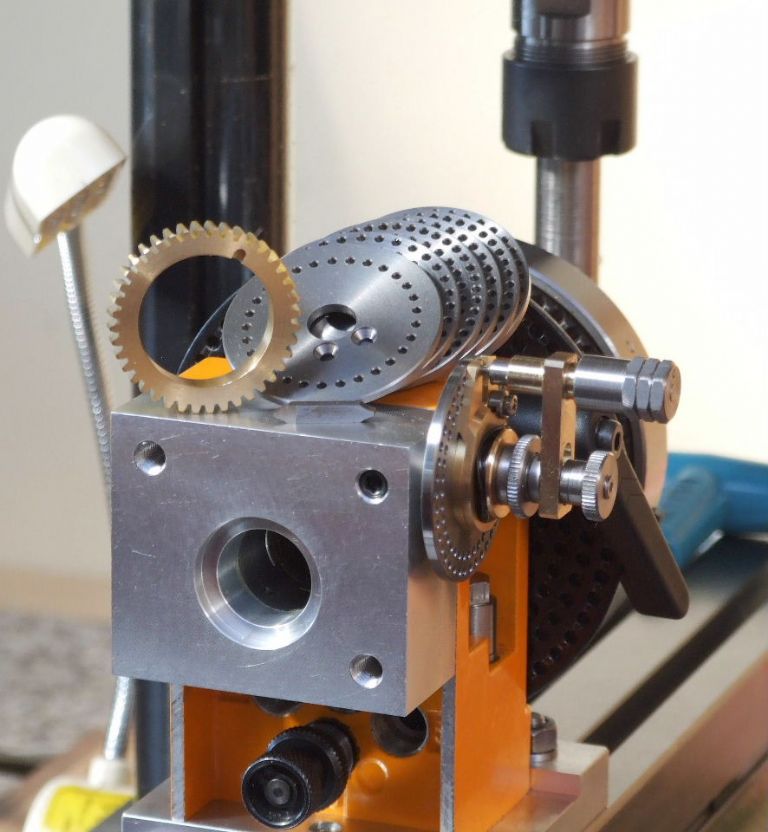

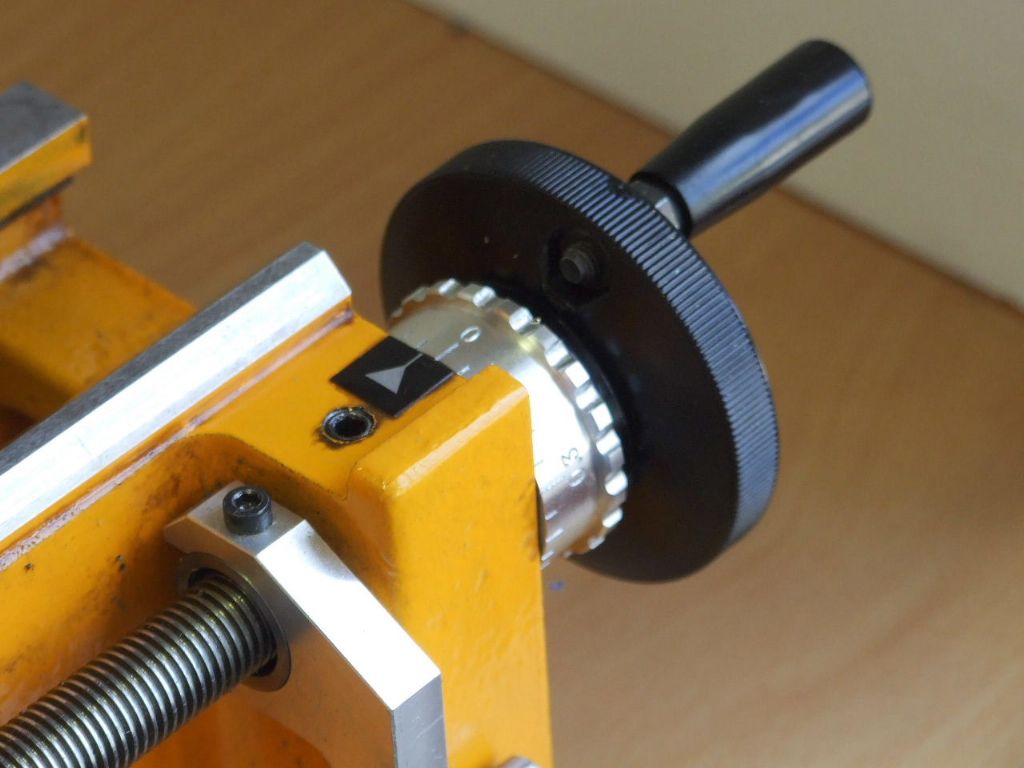

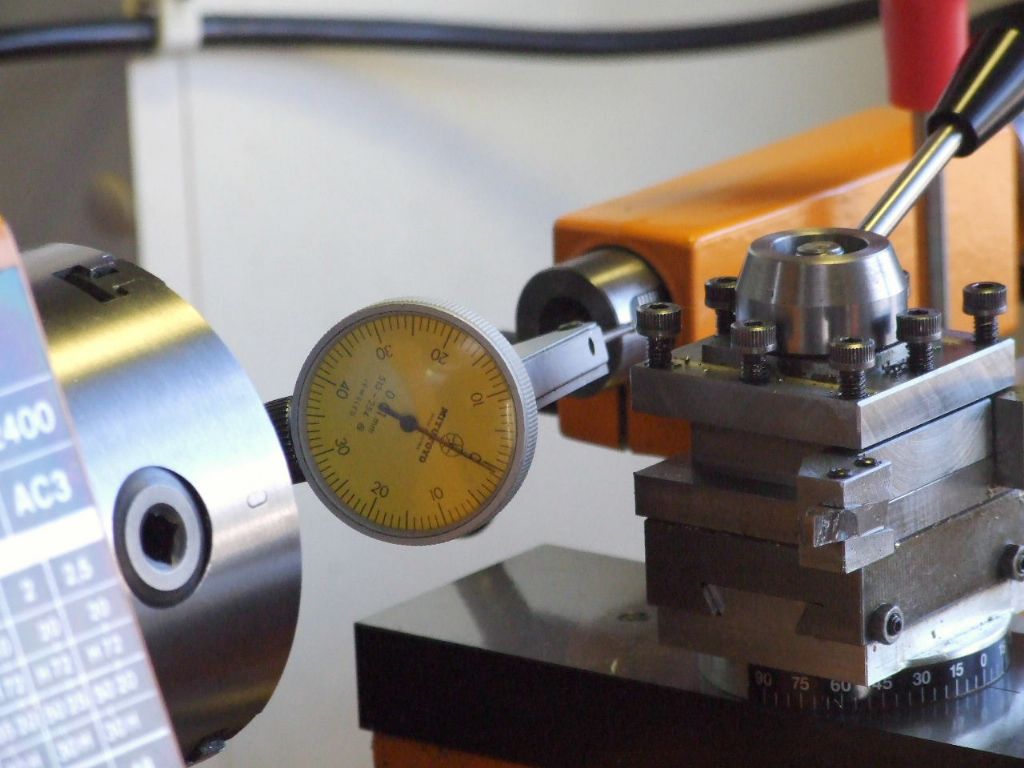

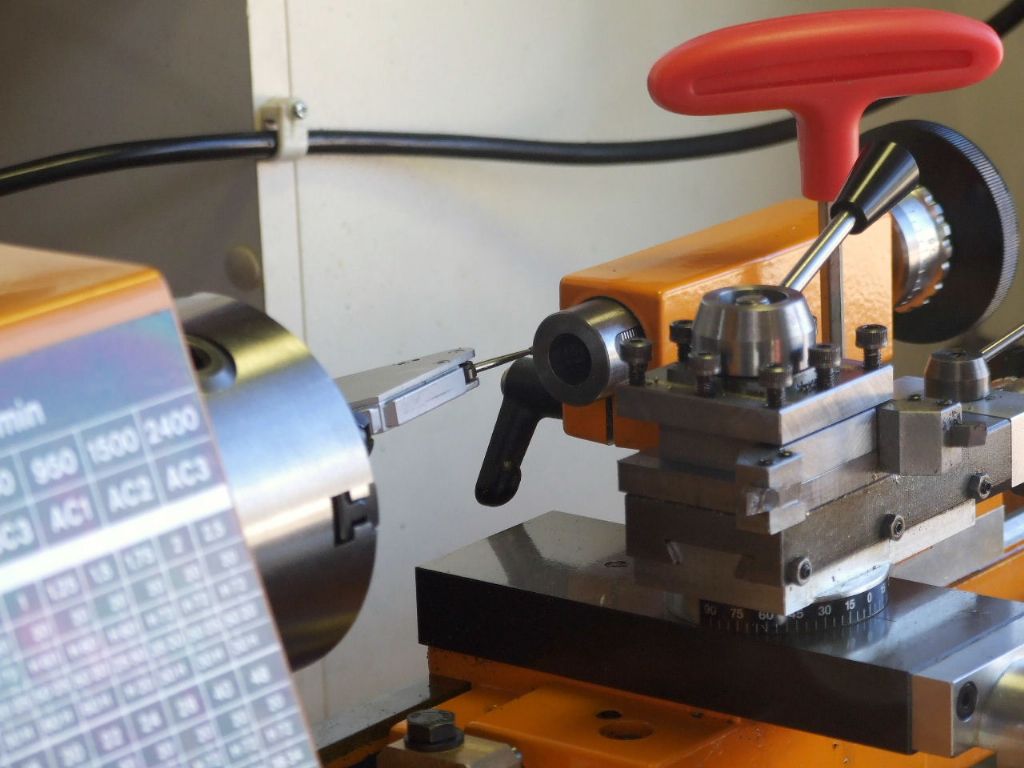

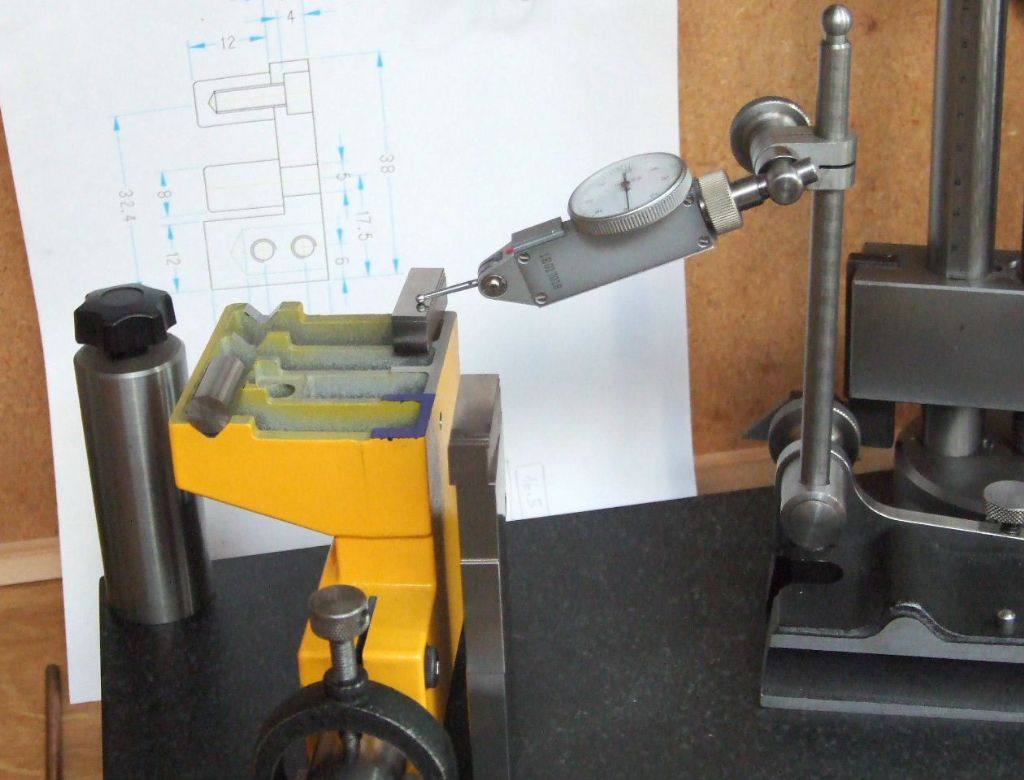

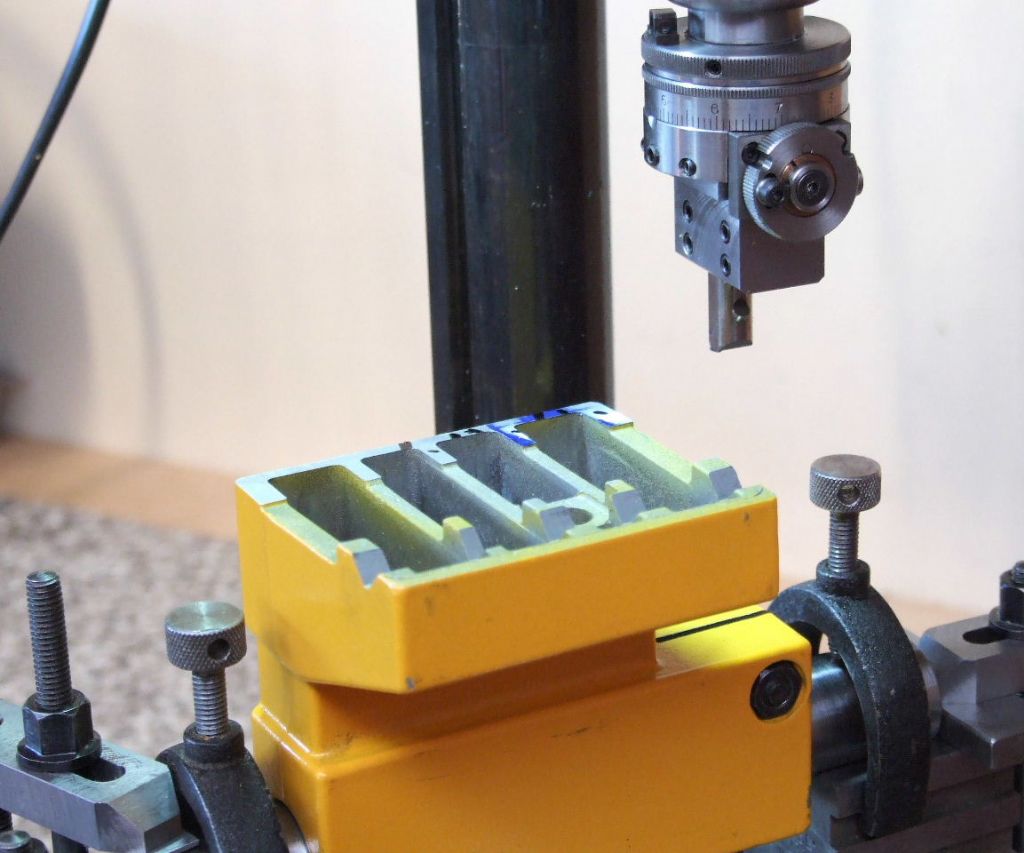

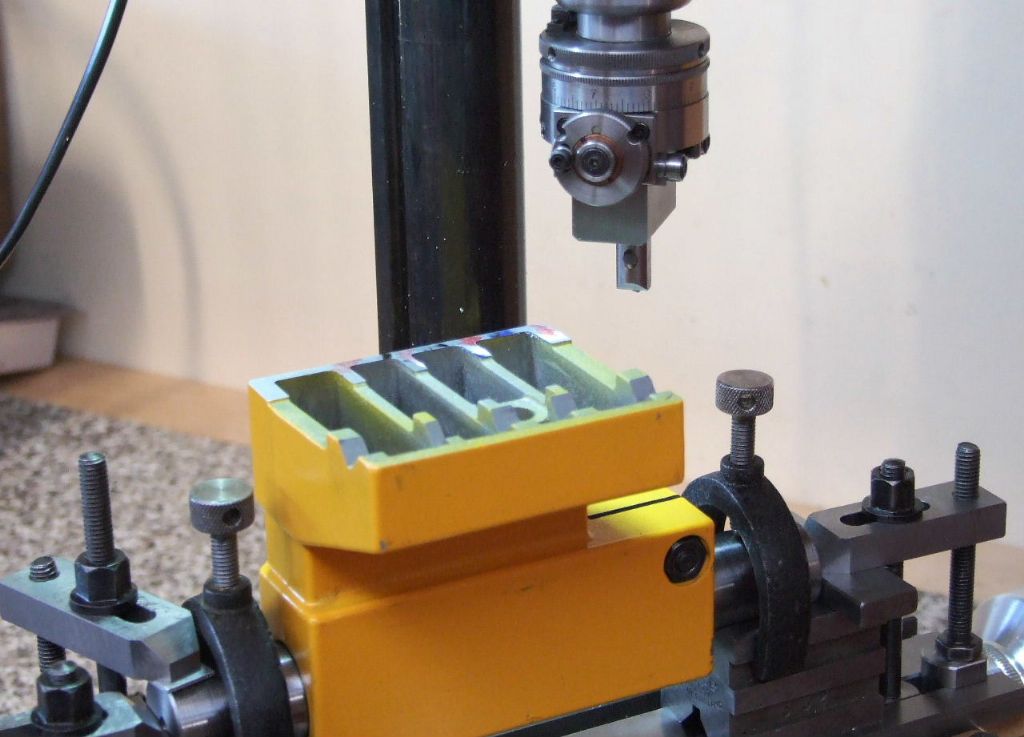

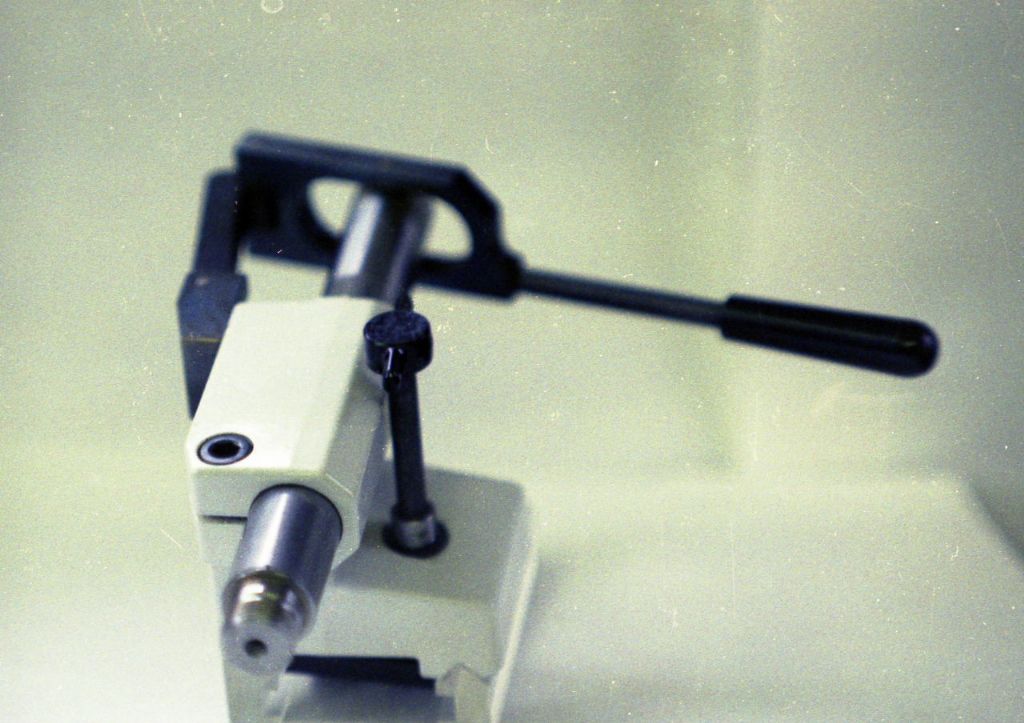

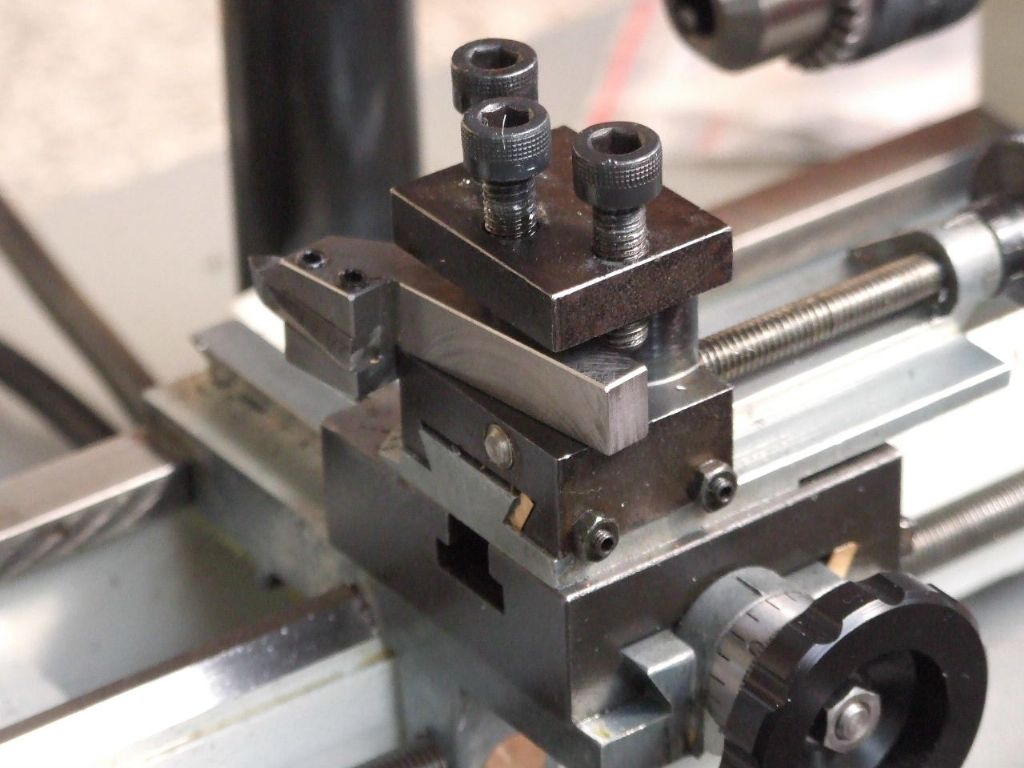

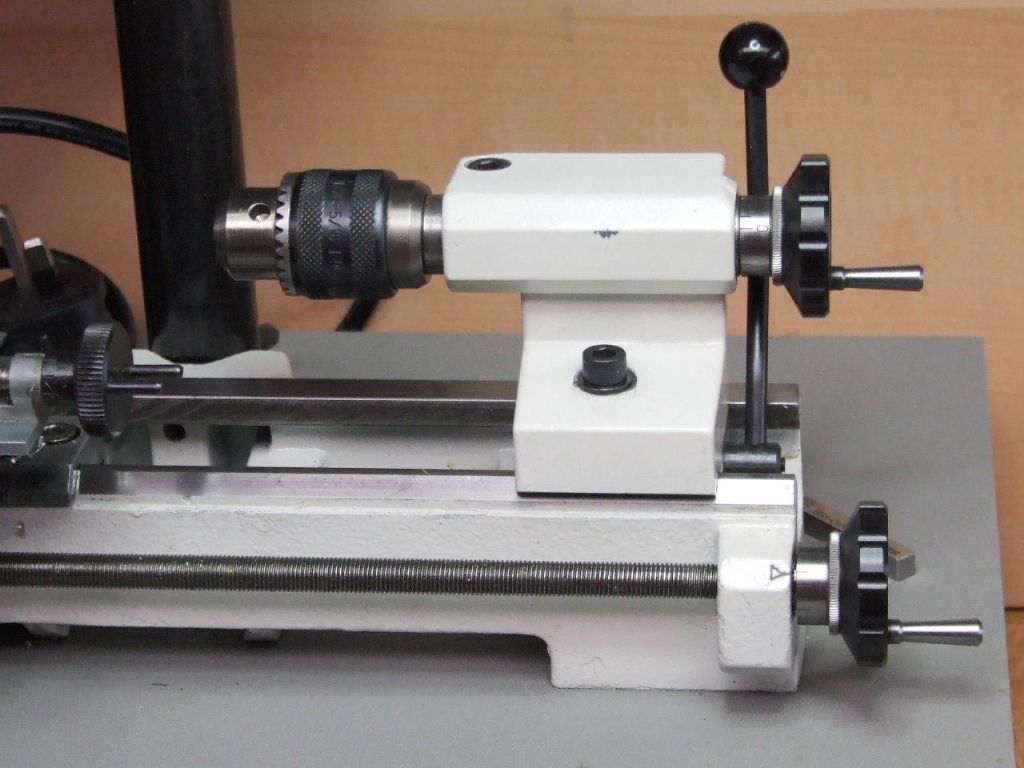

This shows the set-up, note the clamping screw in the tailstock next to the slip stack.

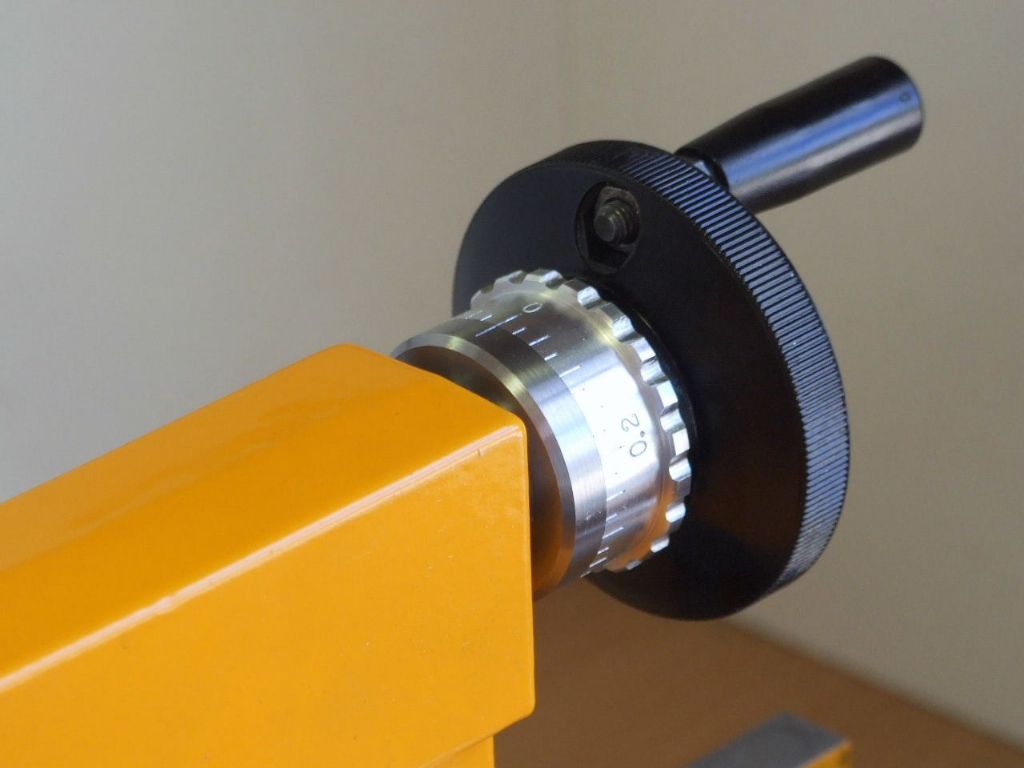

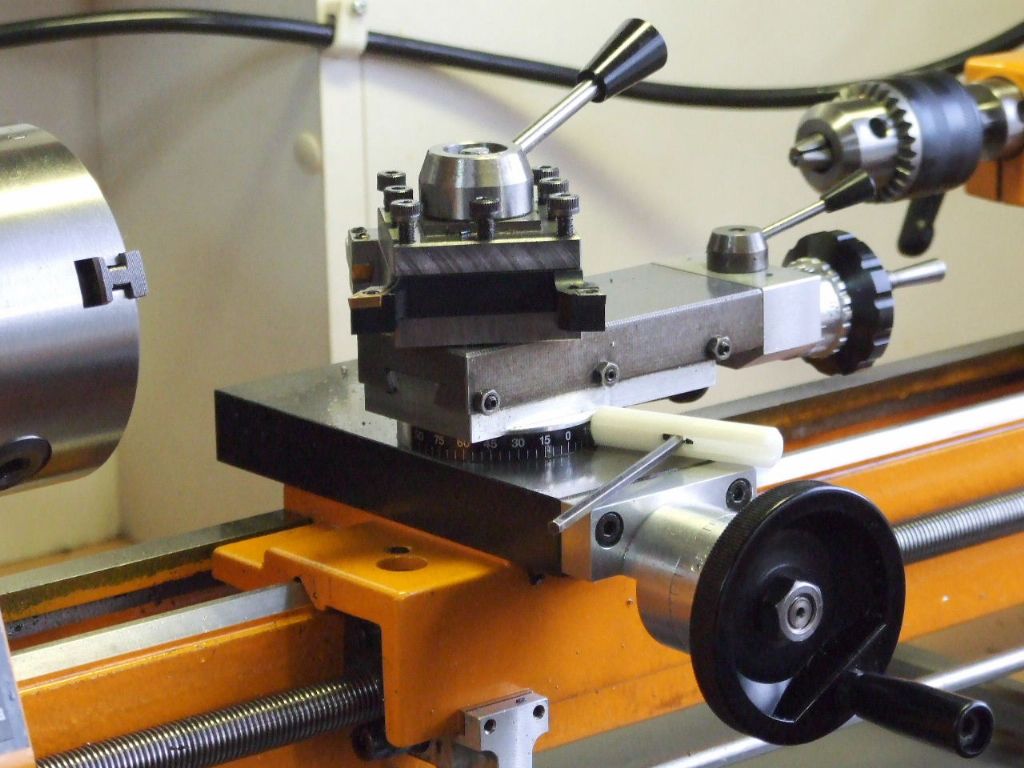

The slips amount to the height of the centre-line of the Mandrel off surface plate. Plus the centre height of the lathe and an additional 10.48 mm. This last dimension was assessed from the Headstock of the Unimat 3 that I refurbished as well as the new Carriage purchased from Austria.

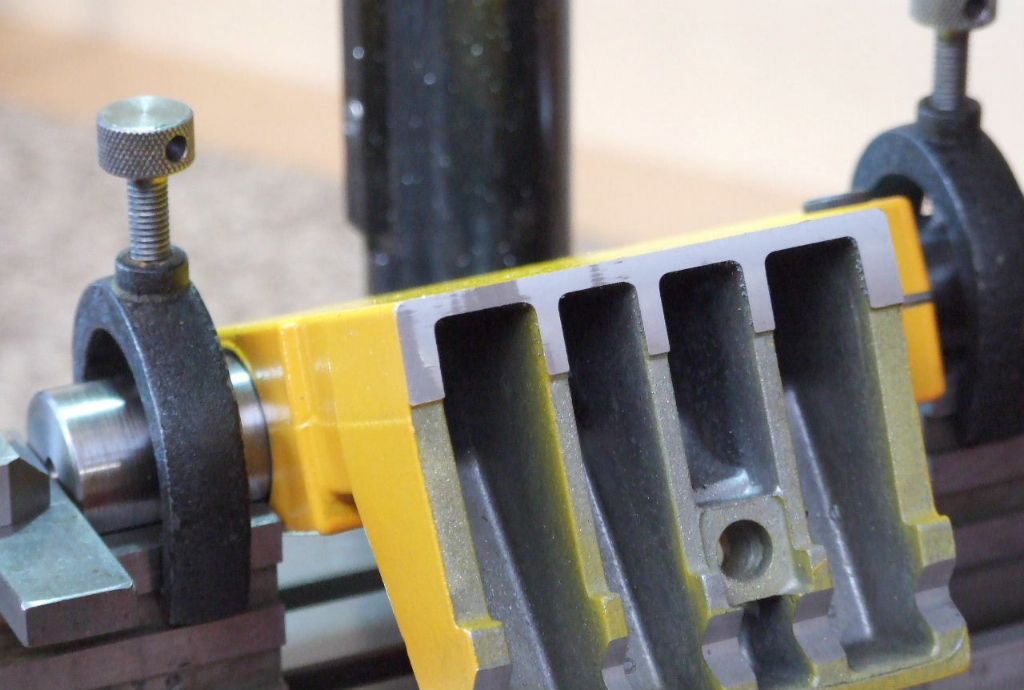

The dimension is the height of a 10 mm diameter roller resting in the Vee in relationship to the flat on on the headstock or tailstock body.

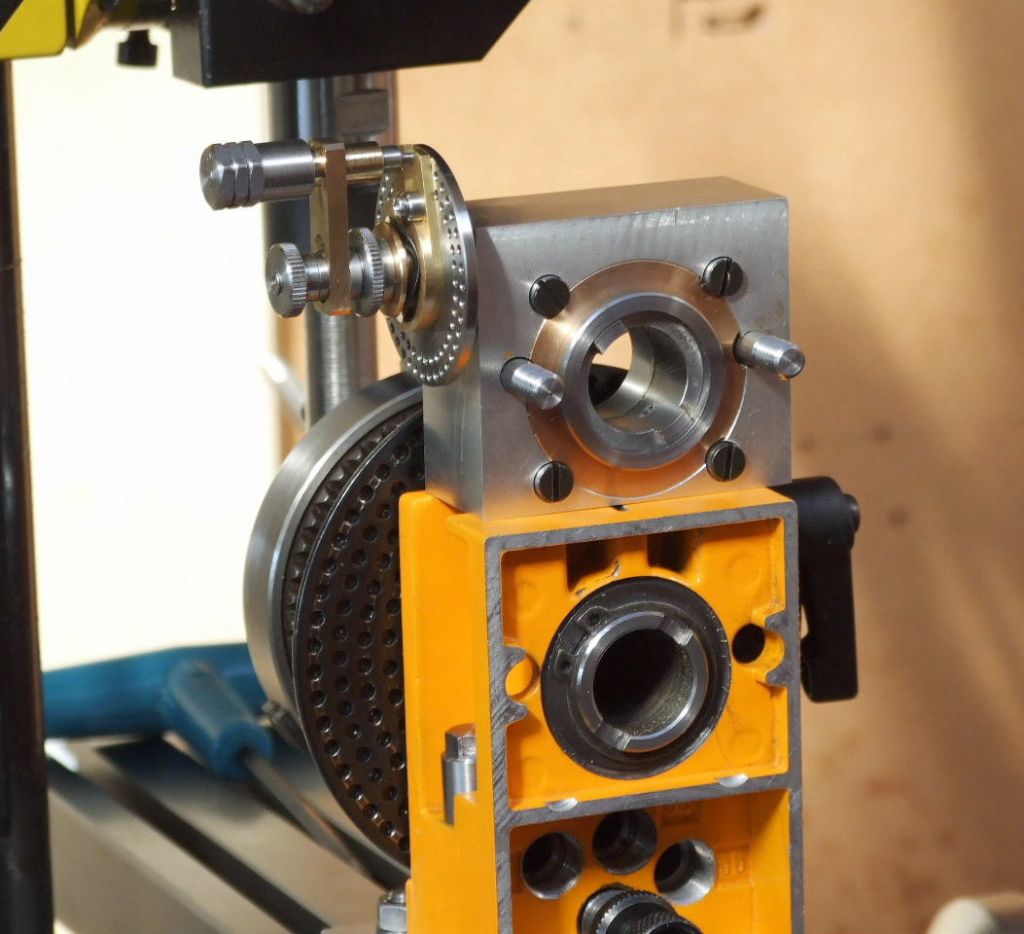

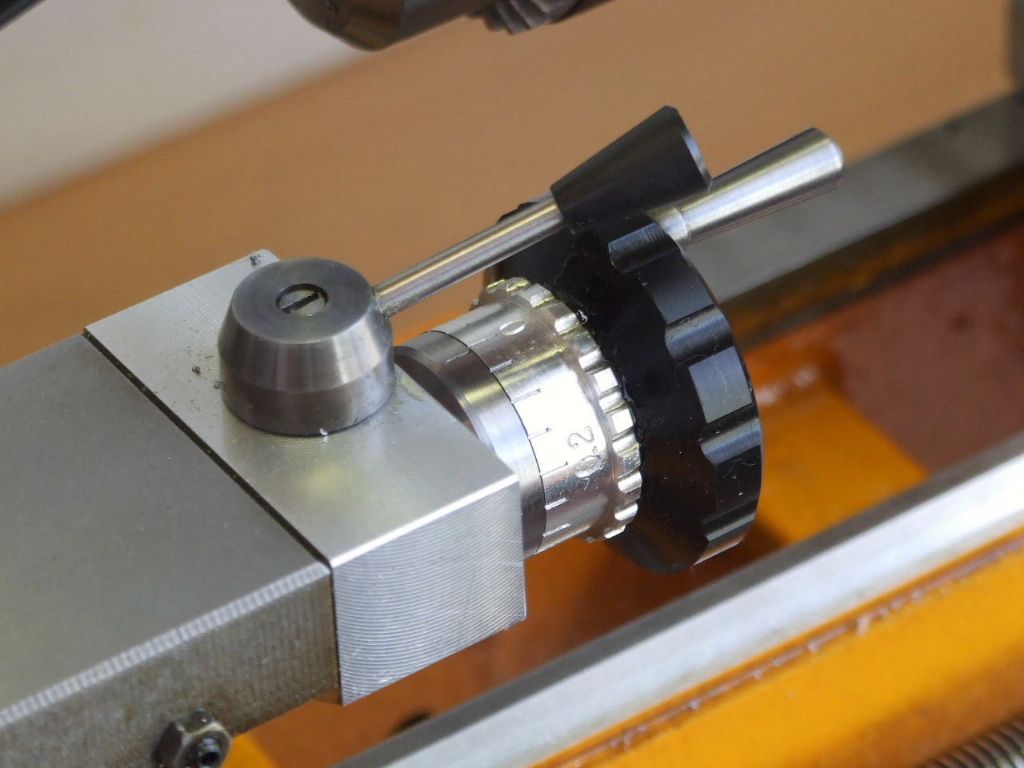

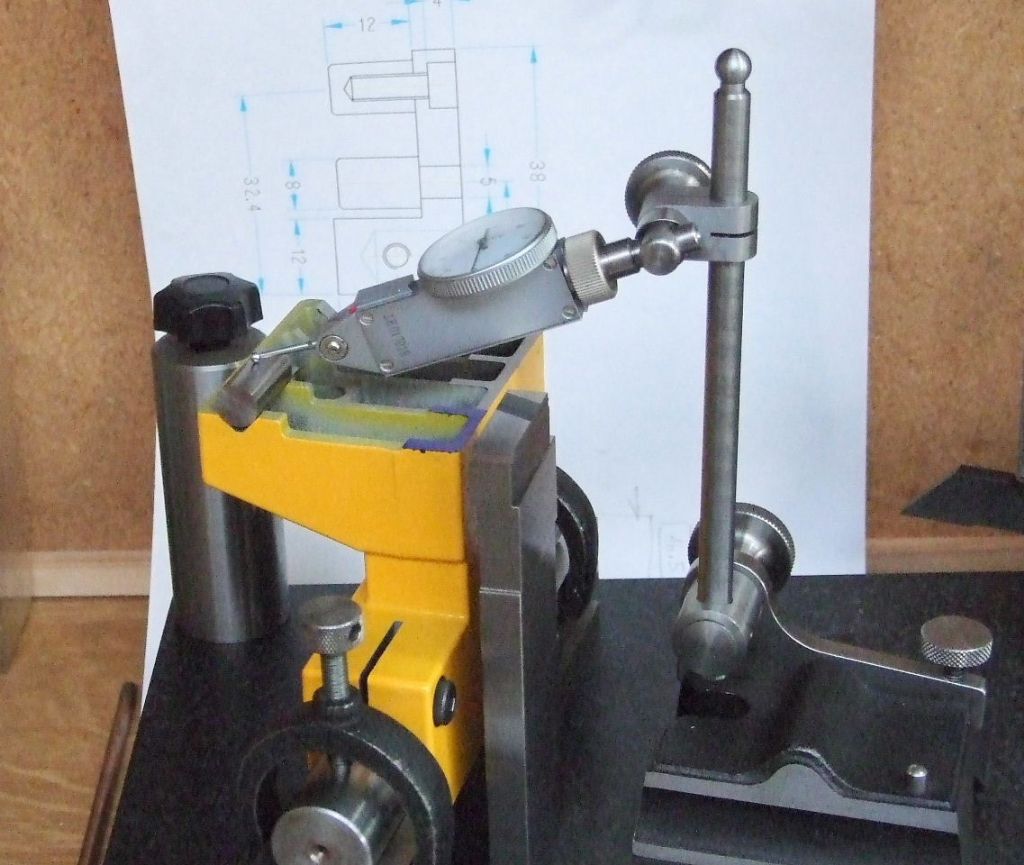

The clock is then used to get the roller to the same height as the slip gauges. Once this is done the Vee block clamps are locked. The roller was then moved to the other end of the Vee way and checked with the clock at the same setting. It was as I suspected parallel to the table, which meant the flat was going to be at fault.

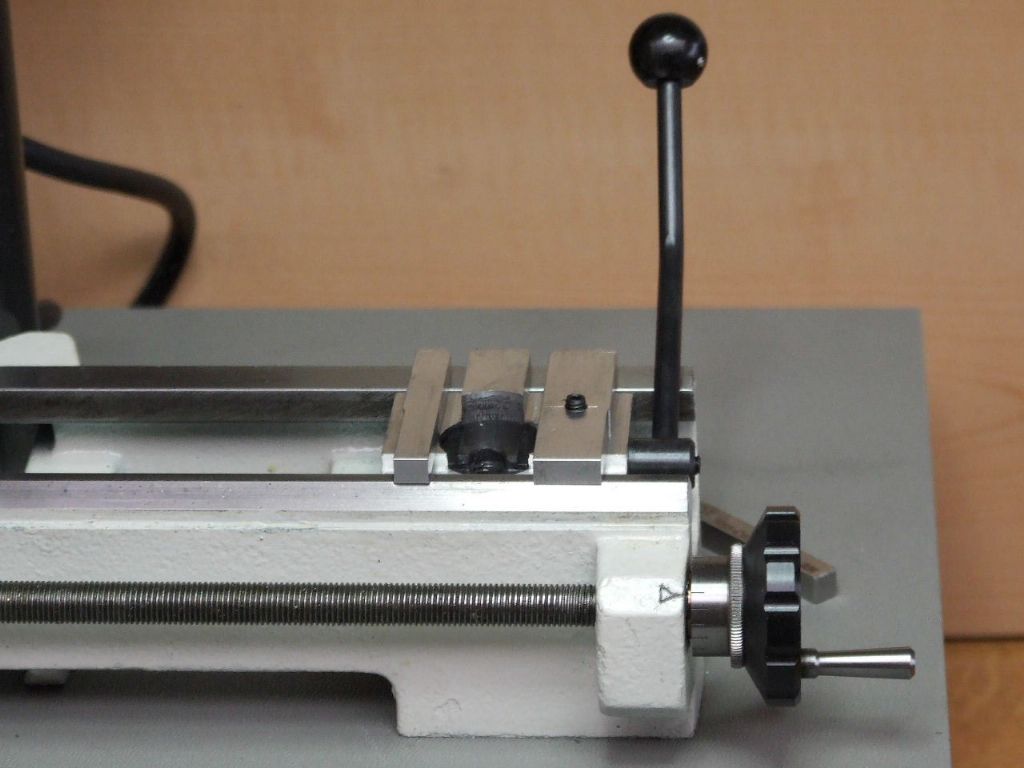

Using the 10.48 mm stack of slip gauges the clock was run over the flat. Whilst at the back in this shot it is where I would want it to be at Zero.

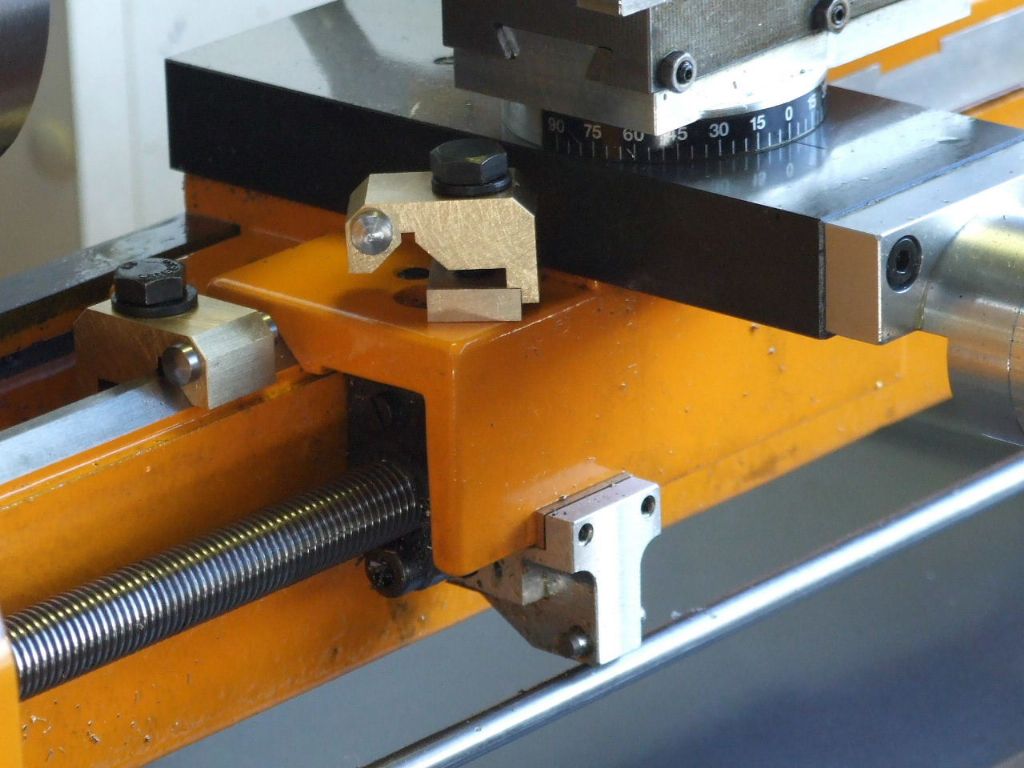

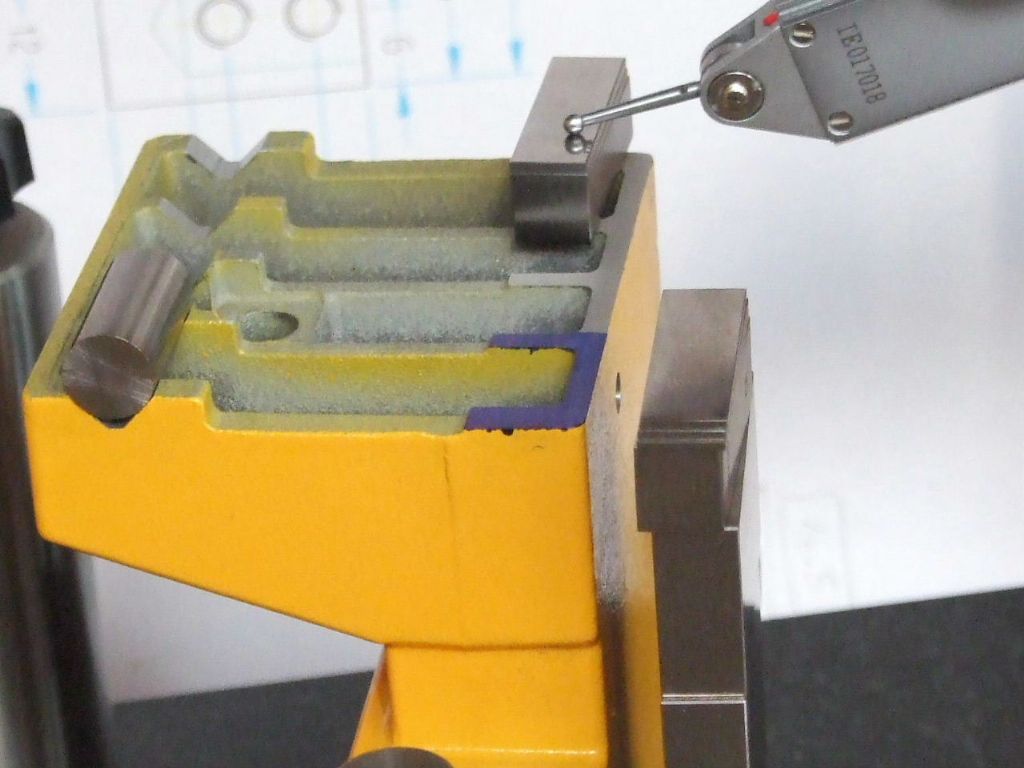

The area of Blue Marker pen shows that this area is higher by 0.03 to 0.04 mm. This confirms the displacement of the tailstock body towards the Operator, and the rocking from corner to corner.

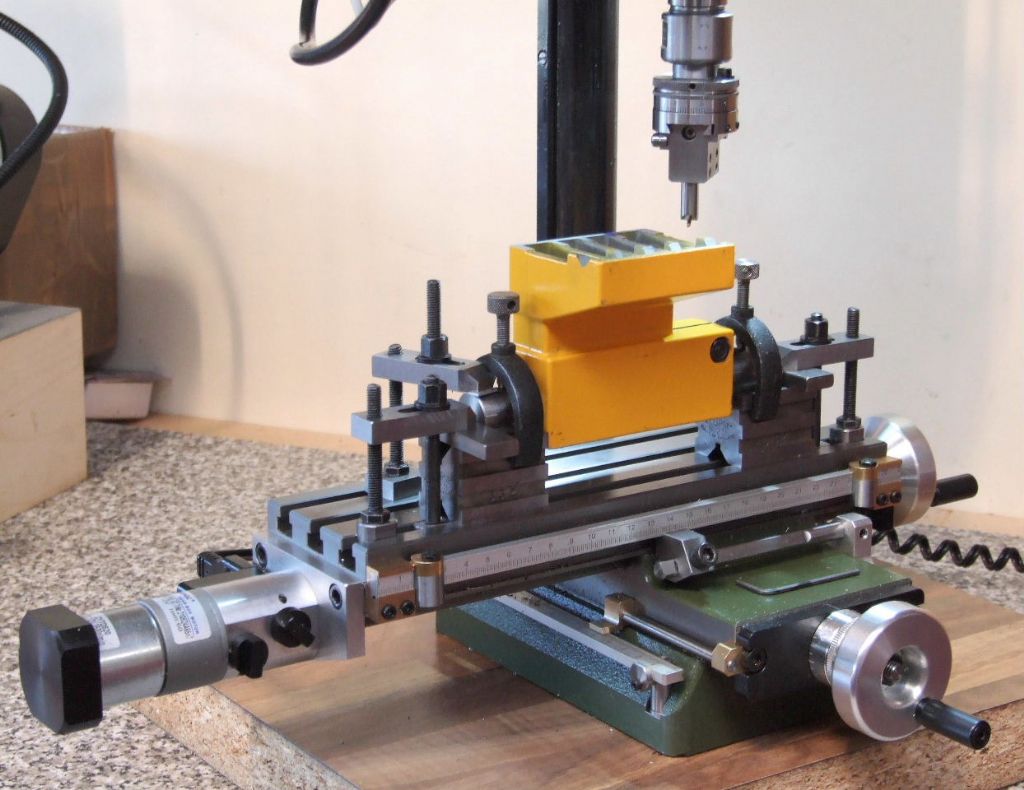

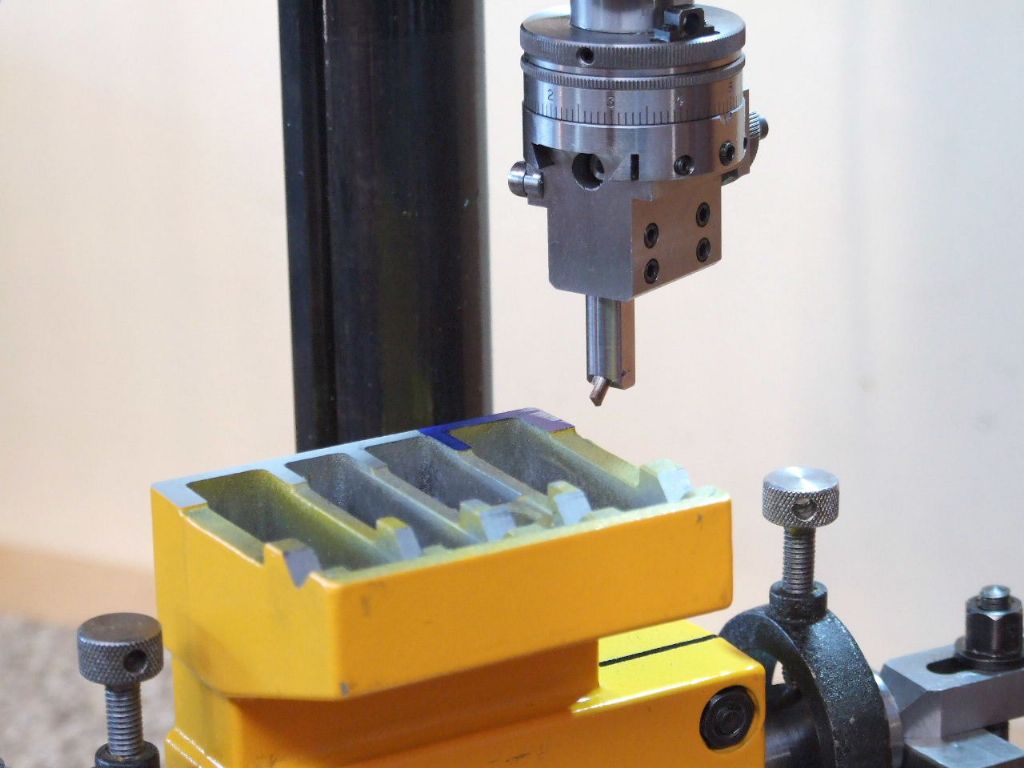

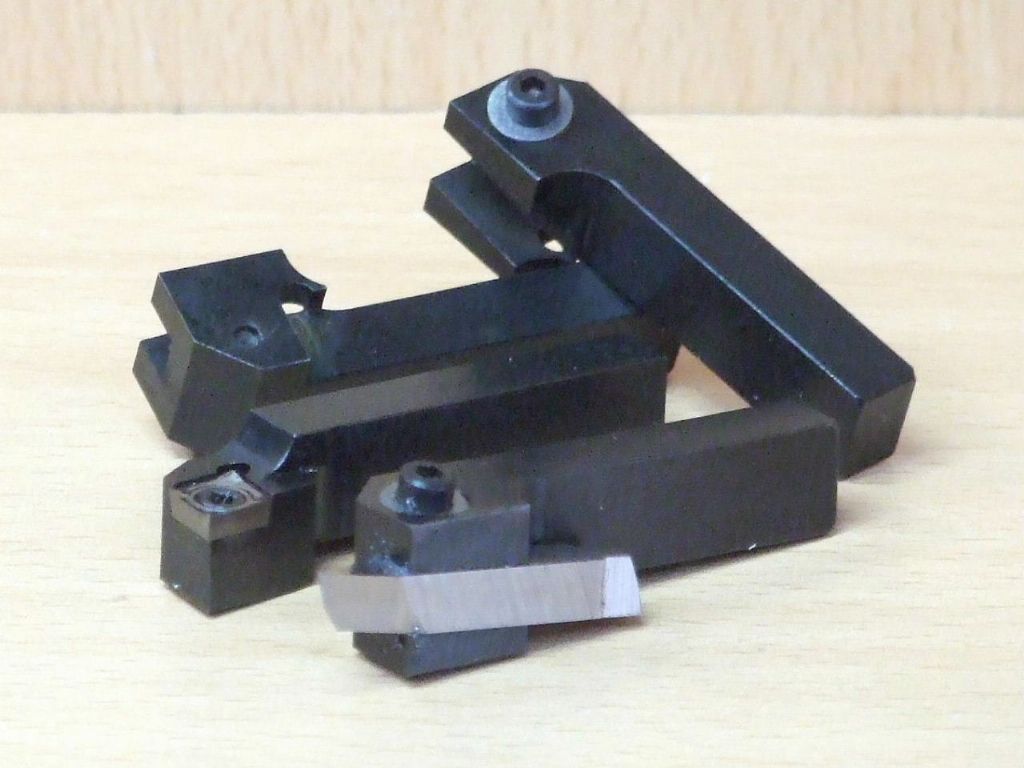

Next time we will mount it on the Proxxon Mill.

Regards

Gray,

Graham Meek.