After deciding to downsize my workshop in January, the need to get the Compact 5 (C5) up to a standard I was comfortable with became a priority. The use of my larger machines would be of benefit while they were still here.

Having had the luxury of the Screwcutting Clutch on the Maximat Super 11 it was something I was not happy to do without. The C5 had always been tempting me to do this mod, so during my recuperation in February I set about designing the attachment.

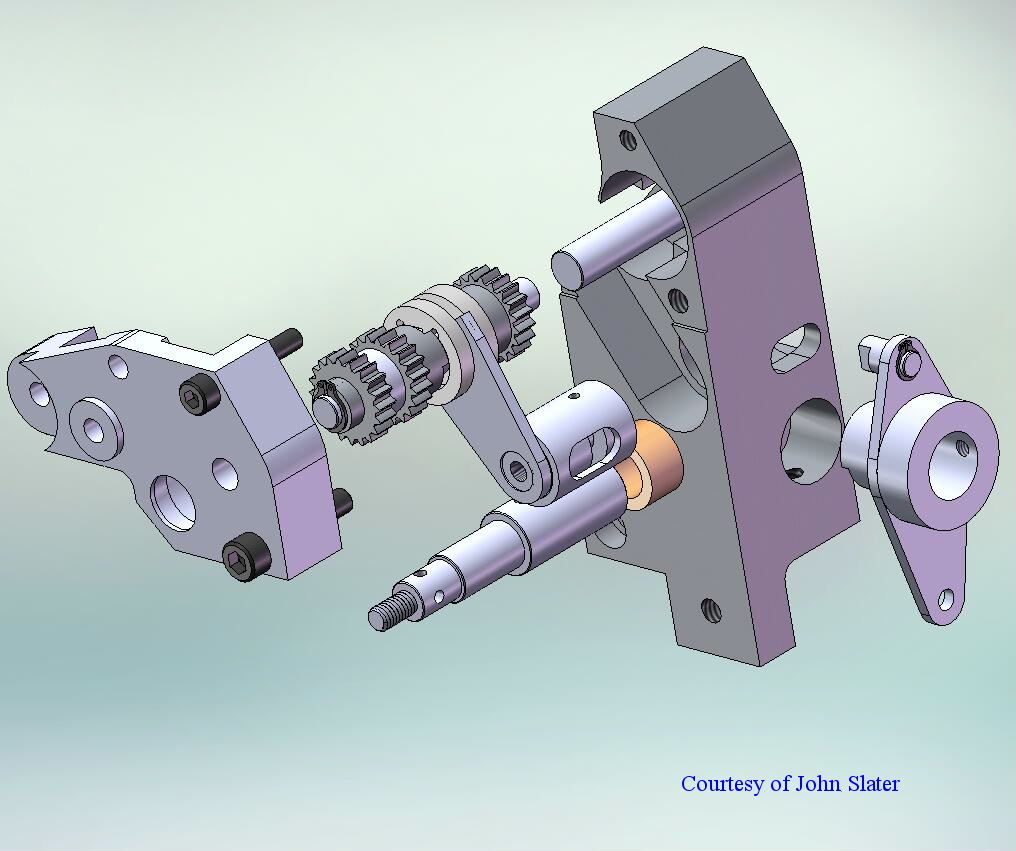

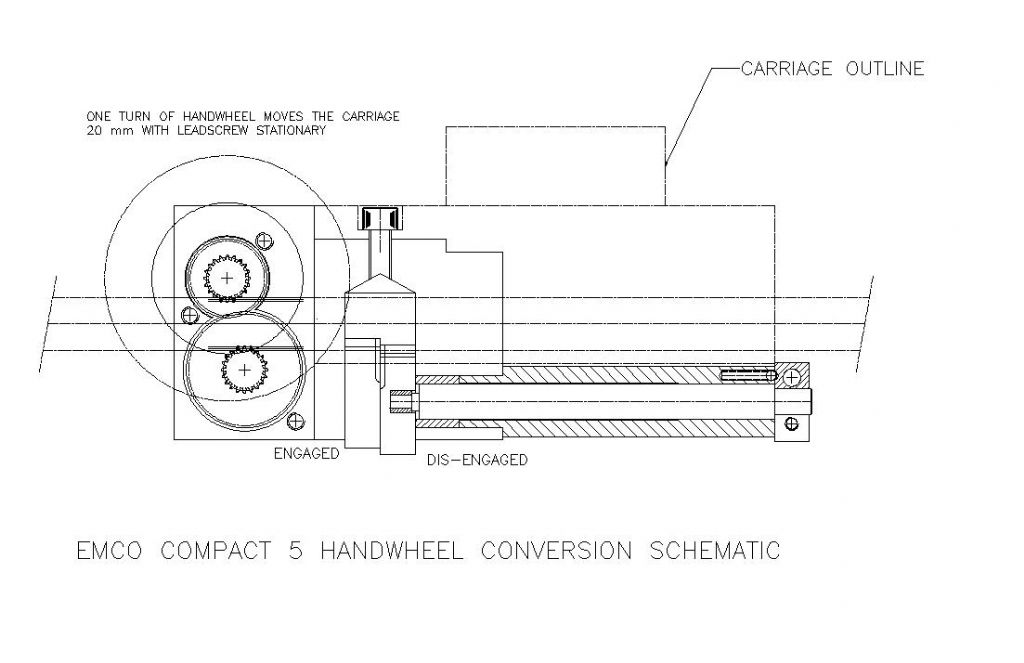

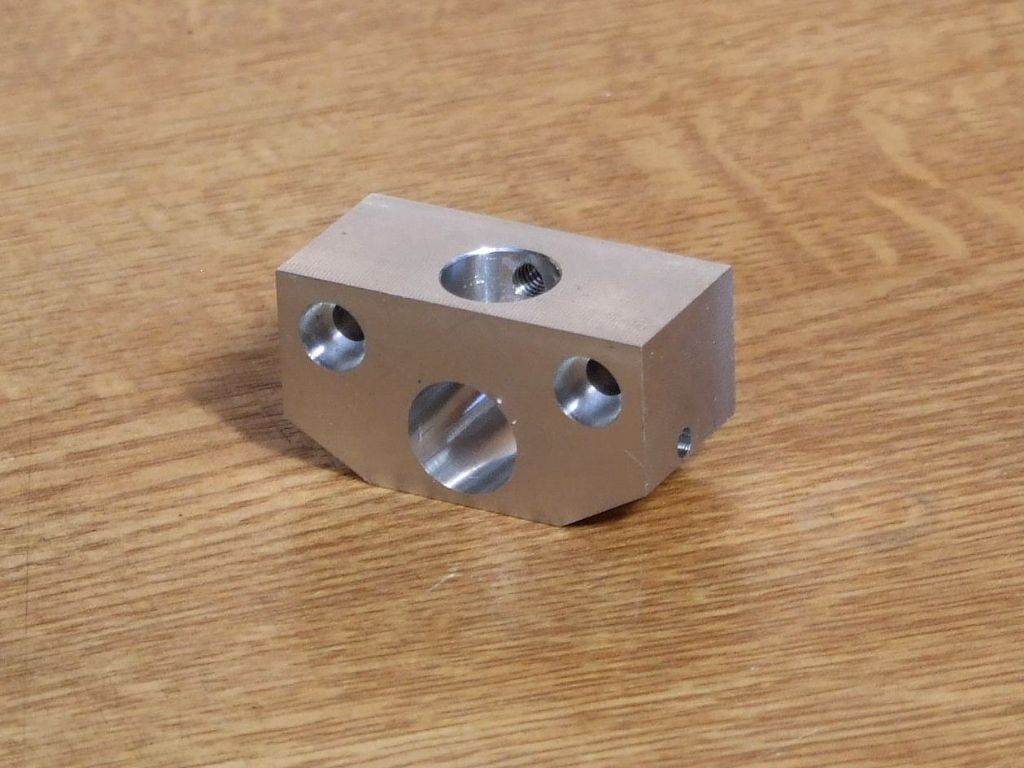

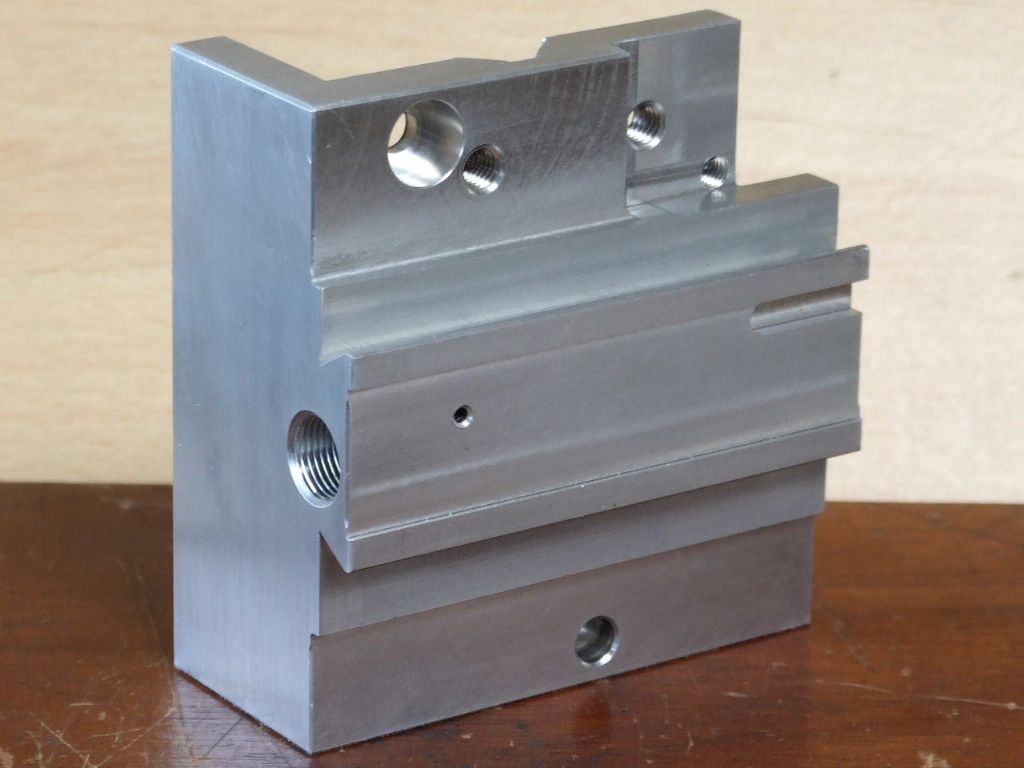

The above view shows the Mk1, and it also shows you really need to be in the workshop more. The reason being I had forgotten to allow for the dis-engagement of the Leadscrew. This being a necessary requirement on the C5, other wise in Manual mode the operator has to turn the banjo gears as well.

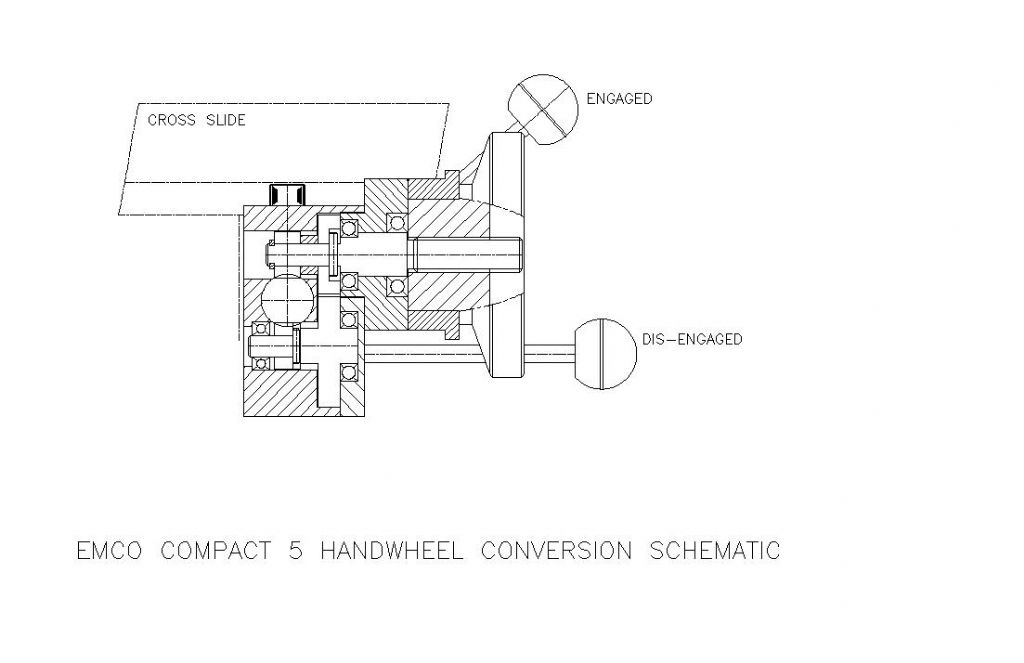

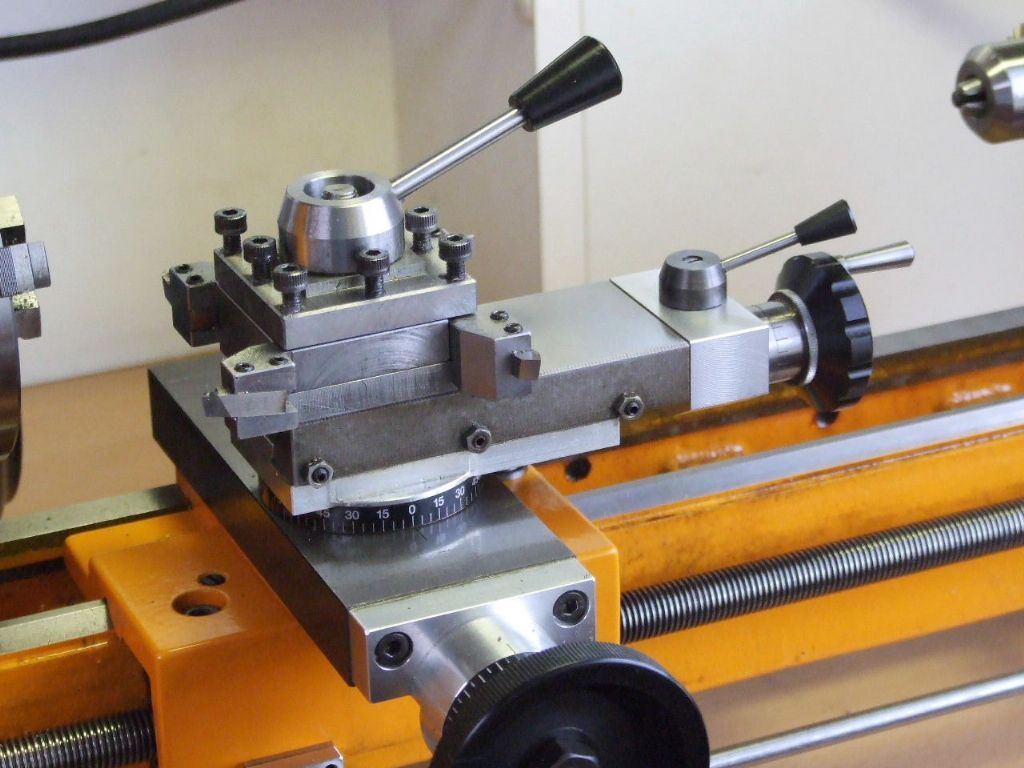

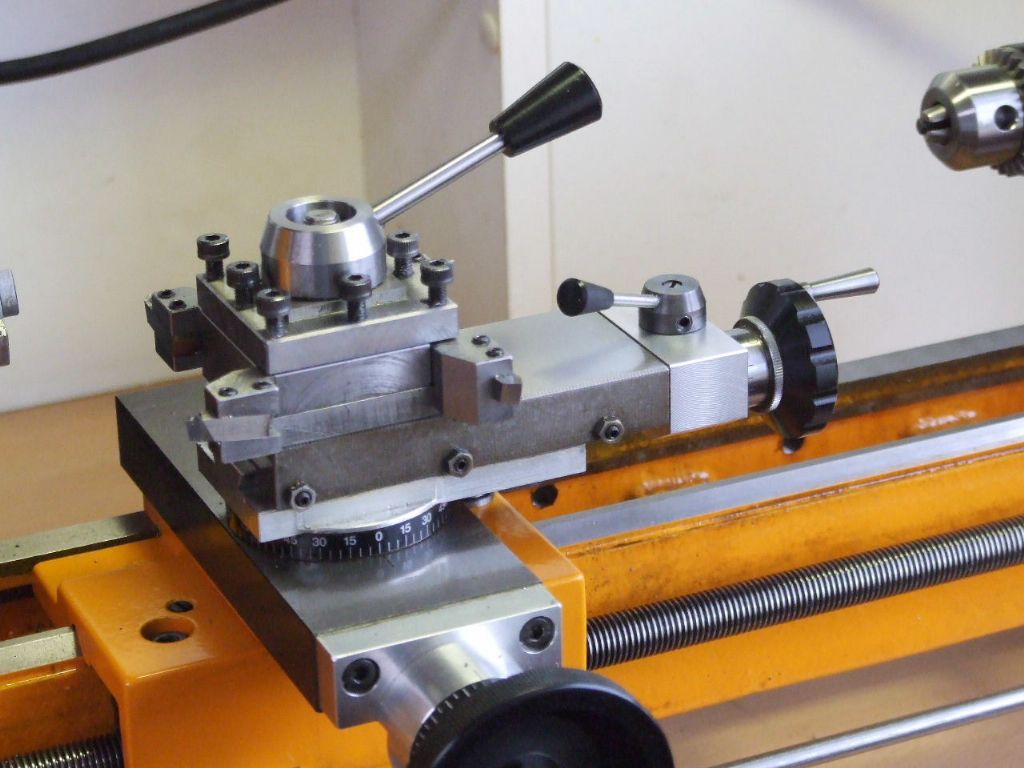

This need to retain the C5 disengagement Knob meant the Operating lever would need to move from the chosen site where the knob was to in front of the headstock. Thankfully during the need to do a complete redesign of the main body it was possible to have both controls in the one place.

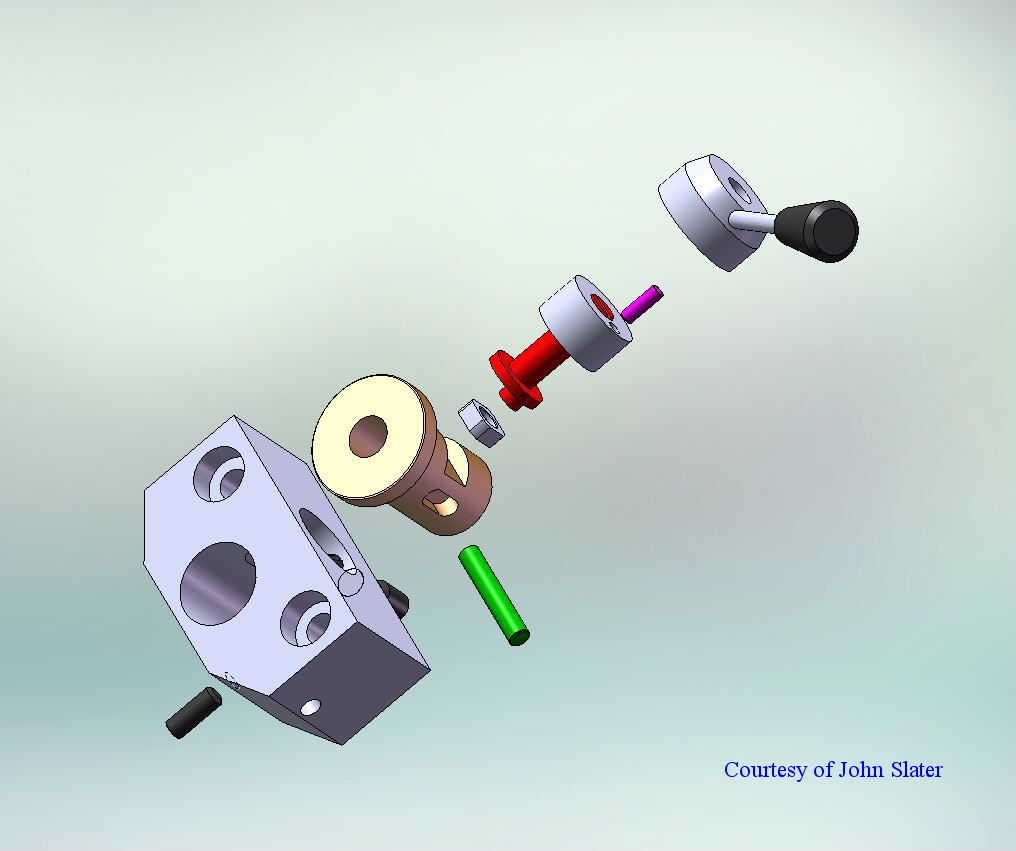

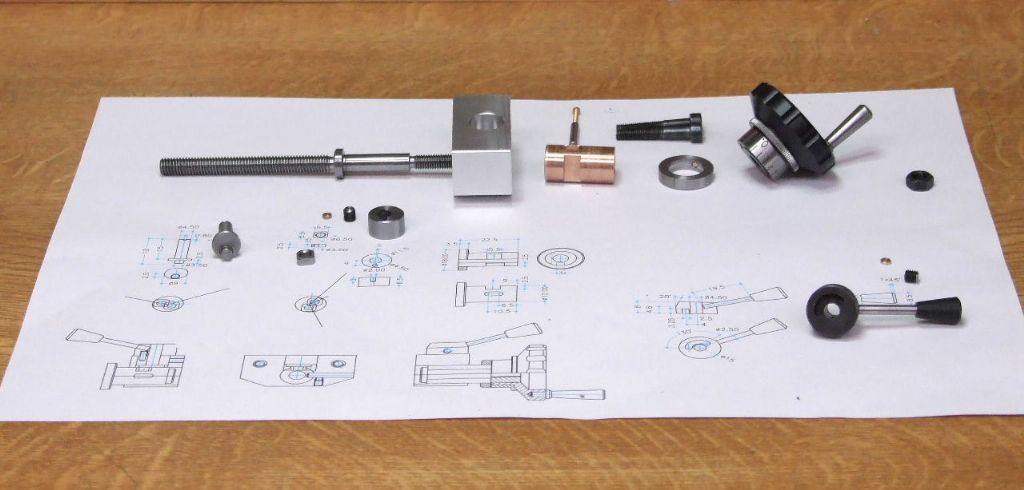

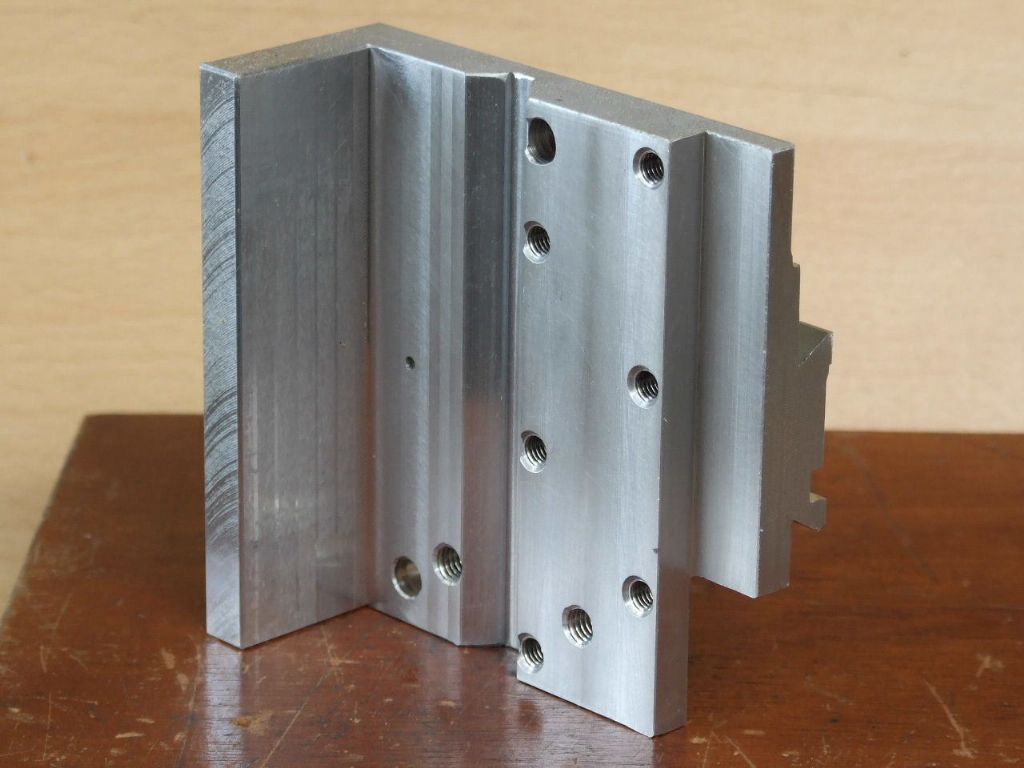

The keen eyed amongst you will notice the main body is now in two halves, or parts. Again had I have been a more frequent visitor to my workshop at the time, I would have noticed the Bracket welded to the inside of the Headstock cover, which takes the cover locking screw.

Had it been possible to retract the leadscrew with drive key attached through the bearing in the lathe bed, then the original design would still have worked. Unfortunately the key stands proud of the shaft and this cannot happen. Thus there was nothing to do but start again with two halves, and yes this was after I had machined the main body in one. Of course I could have cut the bracket off, but that is not how Graham operates.

The redesign also threw up another problem, in that the Dog Clutch, because of the split line needed to sit higher in the upper part of the main body. Unfortunately this brought the dog clutch selector into conflict with the drive belts when changing to the lowest Mandrel speed. This was eventually overcome by machining a flat on the selector similar to the flank on a camshaft. An eccentric balance weight is yet to be made and fitted to the outer end of the selector shaft.

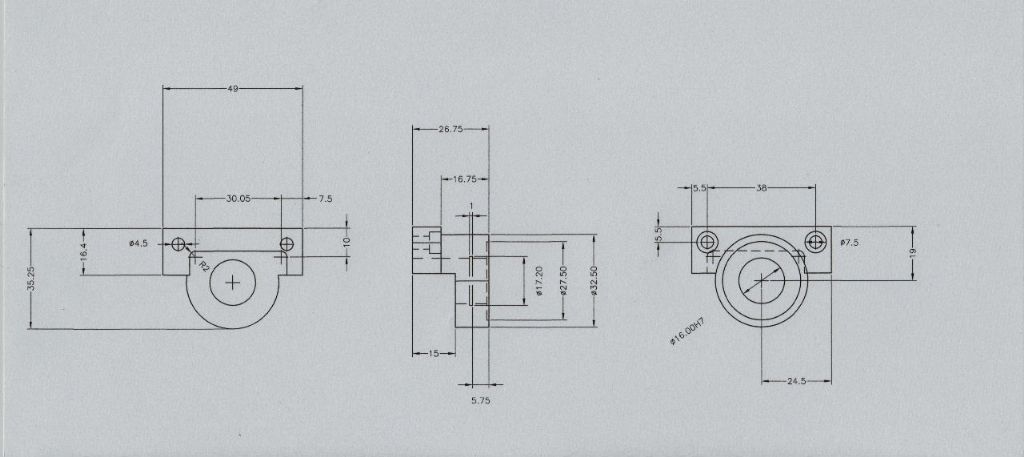

A new bearing assembly was also made for the Leadscrew handwheel which has some Radial ball bearings in. The housing was extended towards the Headstock to provide the anchor point for the outer Trip Rod support. The ball bearings will eliminate wear to the leadscrew end face and give better repeatability when screwcutting.

While I have used this lathe for screwcutting in the past, it was a rather hair raising experience. This attachment now completely eliminates the heart stopping moment as the tool approaches the chuck jaws.

I will in due course go on to describe other attachments for the C5, two of which get the benefit of the screwcutting clutch. I hope you have enjoyed my rather long winded post.

Regards

Gray,

Edited By Graham Meek on 15/05/2022 11:20:55

Edited By JasonB on 30/06/2022 20:35:31

Graham Meek.