Hi Phil,

I have already assembled the cover you offered on the box I bought from England. It fits well but only after cutting the small curved edge at the corners. My box is therefore different from yours. Interestingly, the day after the assembly of the lid you offered me, the box ordered from China arrived and I could verify that the lid is exactly the same as the one I bought here in Portugal.

So, I have this part of the project almost ready.

I didn't find on the WWW anyone who sold the driver DM542T to Portugal and that's why I bought the DM542. Whatever the differences, I'm not sure, but I read that basically, for my purpose, they are the same. Later, eventually, when the COVID-19 crisis is over, I can buy the DM542T.

I want to go ahead and make the connections to the PCB interface you made.

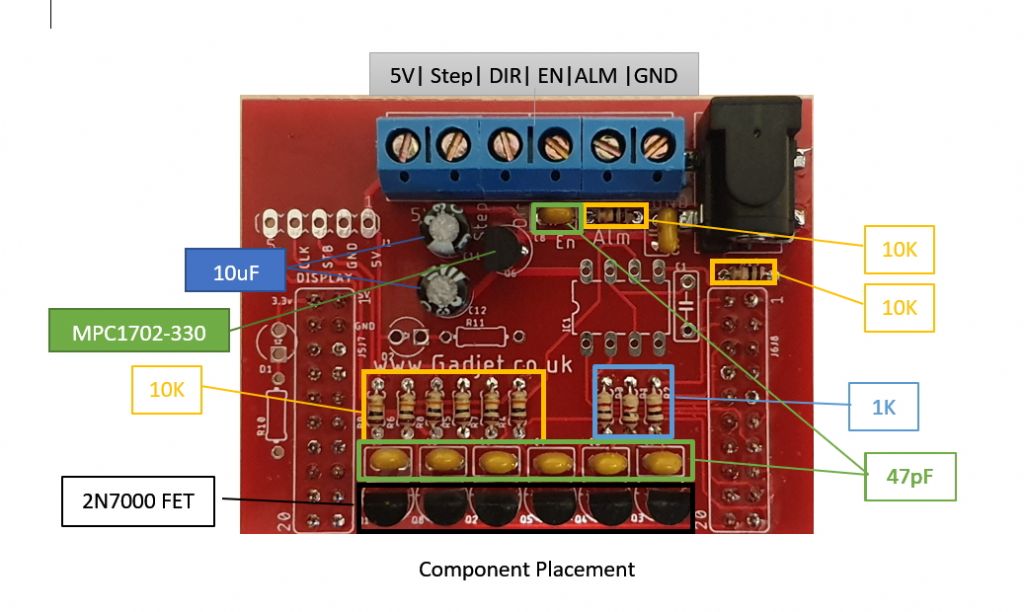

I now need help with the following: The interface you manufactured, has connections that are visually different from those of the Clough interface and also the driver that I have has different connection point designations than the driver that Clough uses. So I can't use the diagram he makes available to support the connections.

Could you please show me the point-to-point connections between the interface board and the DM542T driver?

Can you tell me, please, what does ALM mean? I looked in acronym finder but I didn't find an answer that fit.

Thanks in advance

Dias Costa

John Hinkley.

John Hinkley.