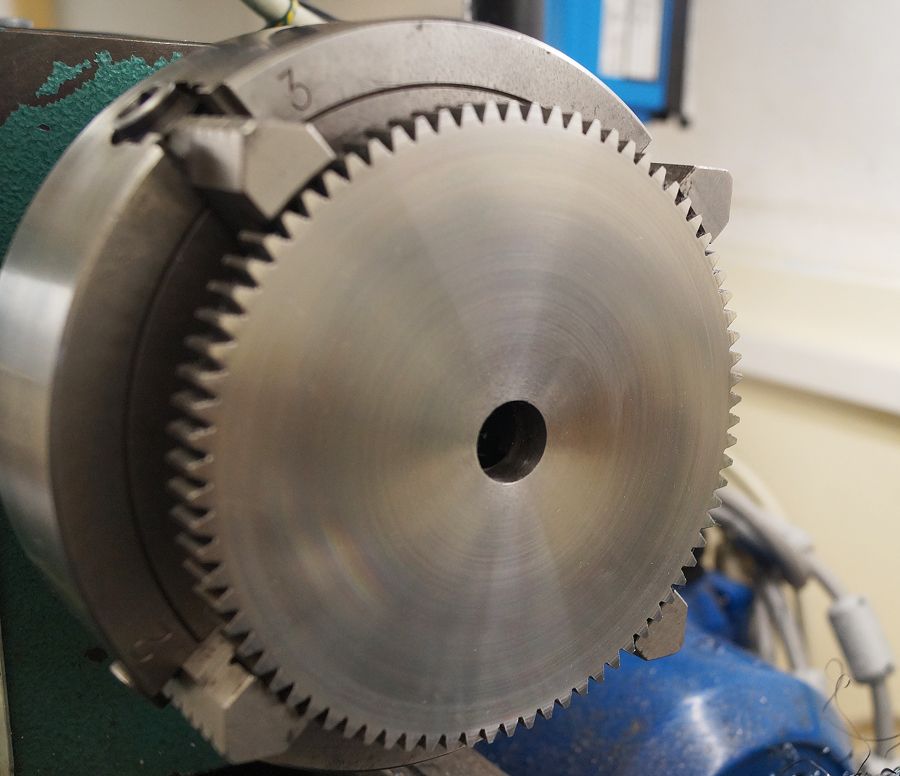

Reduced the large gear from 15mm to 10mm, 80T – 1.5 MOD getting towards 5 inch diameter, I put it up on the lathe as I didnt fancy fly cutting it in 2 passes. I dont know what it is made from, some Chinese concoction but it was awful to machine, really hard work and the hardened teeth didnt help, I wouldnt be in a hurry to do another one.

HSS wouldnt look at it and the insert tool didnt think much of it either, 10 thou cuts was the most I could go with and that was pushing it. Finish is not perfect but quite smooth to the finger so I think it will do. I now have 160 hardened teeth ends to debur and a standard needle file wont have it so probably need to get a couple of diamond type.

I have noticed that the last 20mm towards the centre hasnt cut so well but I suspect that was lack of speed. I increased the speed as the diameter of the cut reduced but I was in mid speed range which was probably not enough for the centre. I will wind the speed up later and see if a light finishing cut improves it.

Edited By Ron Laden on 07/09/2019 09:51:00

Edited By Ron Laden on 07/09/2019 09:56:31

Ron Laden.