Posted by Paul Kemp on 03/04/2019 22:26:38:

Posted by Boiler Bri on 03/04/2019 21:18:20:

If you use a reamer to get to size are you not going to end up with a larger hole? Unless I have missed something and your using an adjustable reamer?

All my fixed reamers are over size when used.

Only a small amount.

If you want to borrow an adjustable one I can lend you one?

Bri

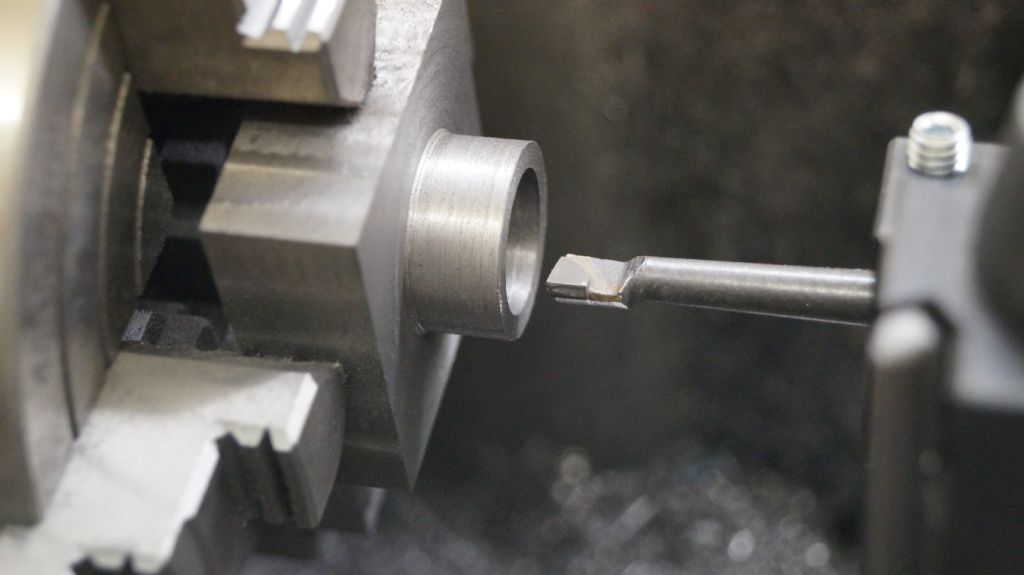

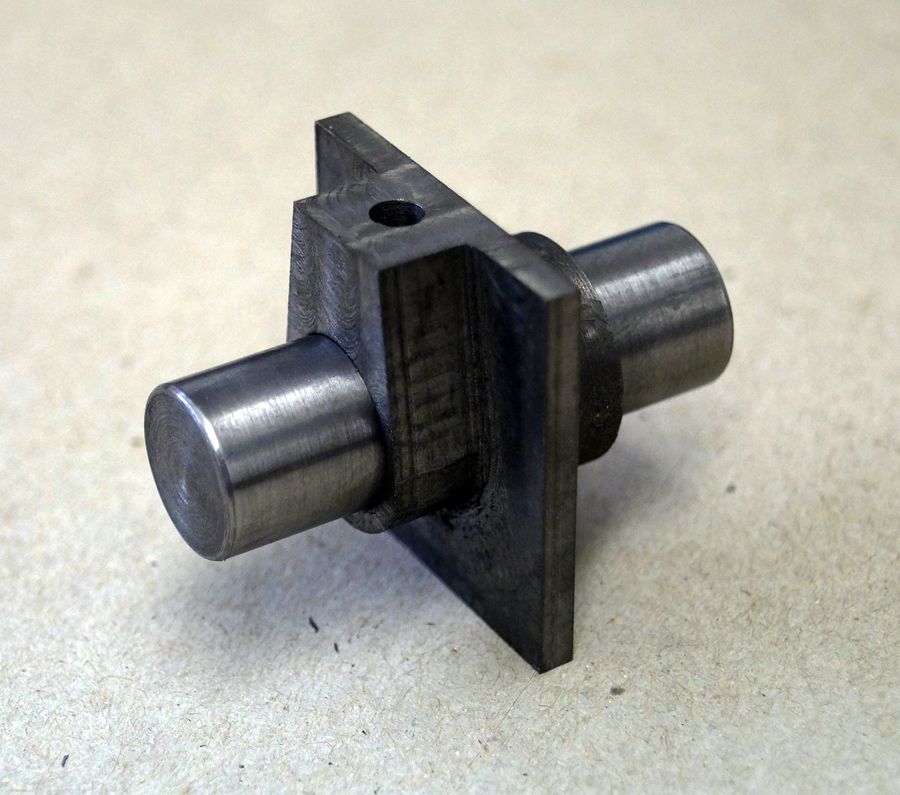

Well generally for what Ron is trying to achieve you need a bit of oversize or undersize somewhere if a shaft is going to enter and be free running in a hole. If your reamer makes the hole exactly 16mm and the shaft is exactly 16mm then a decent running fit is unlikely. Professional reamers are made in a variety of tolerances to allow for this, the general hobby reamer will make a hole with a little clearance in which a shaft of the nominal size will run. Remember oil takes up space too so it's always good to leave a bit for it to do its job. Size for size is not a good free running fit. If you want to make the hole and shaft a press fit then you really have to look at tolerances. For general running fits a general purpose reamer is fine. I have just made a 1 1/8" hole into which I need to press fit / shrink fit a bush. I used a standard machine reamer for the hole as an easy, quick way of making a hole that is basically round with a good finish, saved setting up the boring head. I will put the interference on the OD of the bush when I turn it after measuring the hole.

Paul.

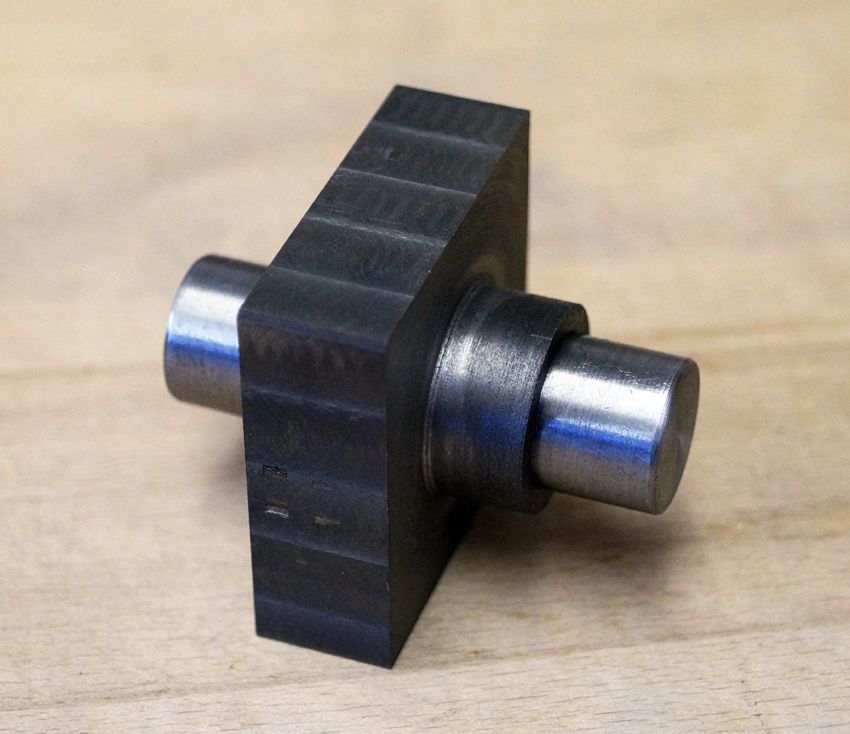

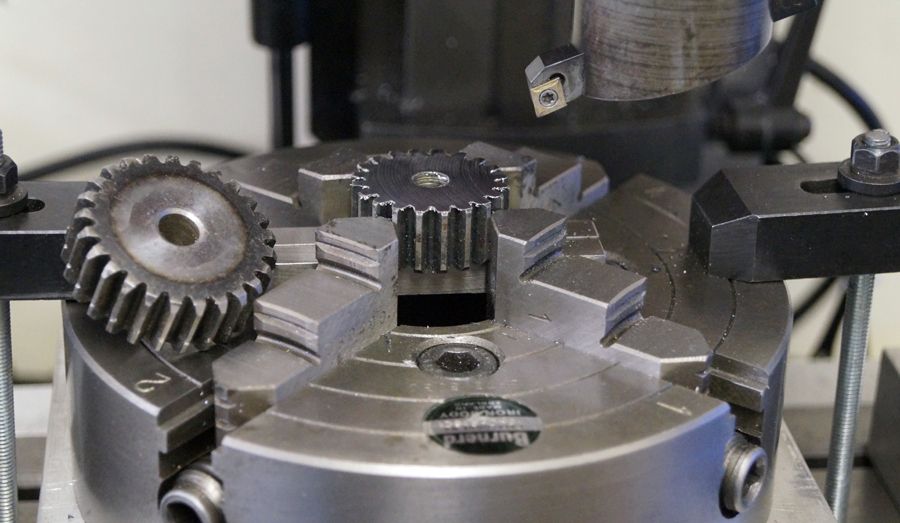

As I mentioned once I have the 16mm ground bar I will use that as the gauge and bore to achieve a good running fit, dont want to use the reamer in case it cuts too big. I am using ground bar for the axle, crankshaft, 2nd and 3rd shafts so they set the size and associated parts I will machine to achieve the type of fit needed, well thats my plan.

Ron

p.s. Thanks for the offer of the reamer Bri but hopefully I wont need one.

Edited By Ron Laden on 04/04/2019 08:14:31

Ron Laden.