Having a day off from the 22 so have been giving a bit of thought to the drive on the electric T/E. I was planning on mounting the motor in the firebox and having a 12T gear driving the 80T which in turn drives back through the gears to the cylinder.

I though it would be great if it could be driven from the cylinder as per the norm but couldn't see how, until I had an idea last night. Now this a bit off the top of my head so feel free to jump in if I am missing something or whatever.

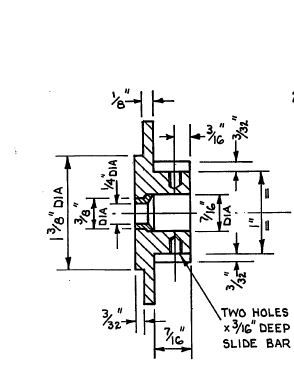

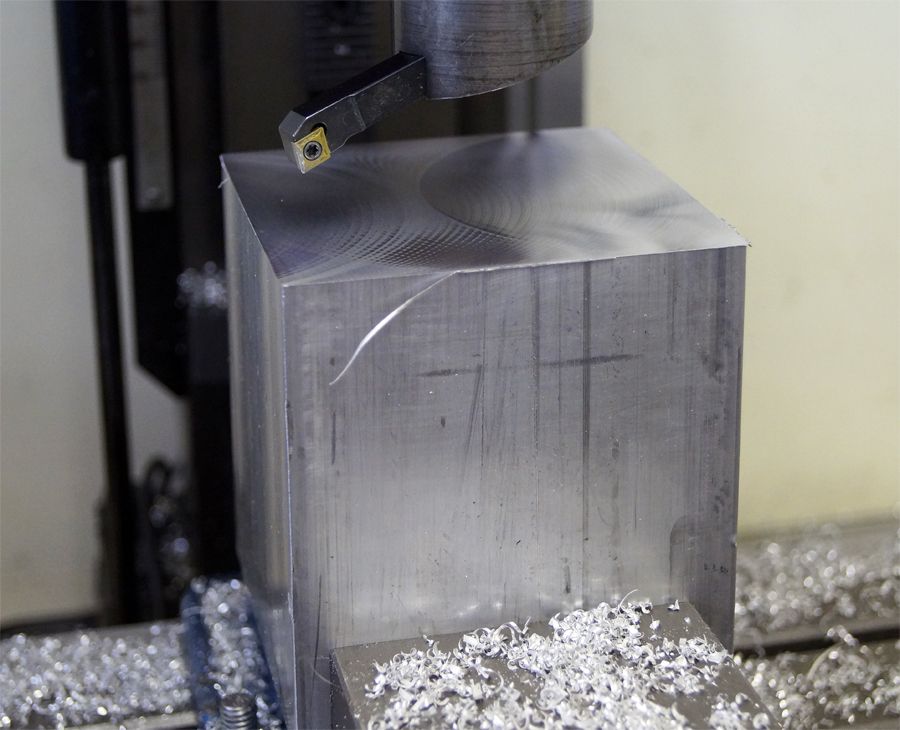

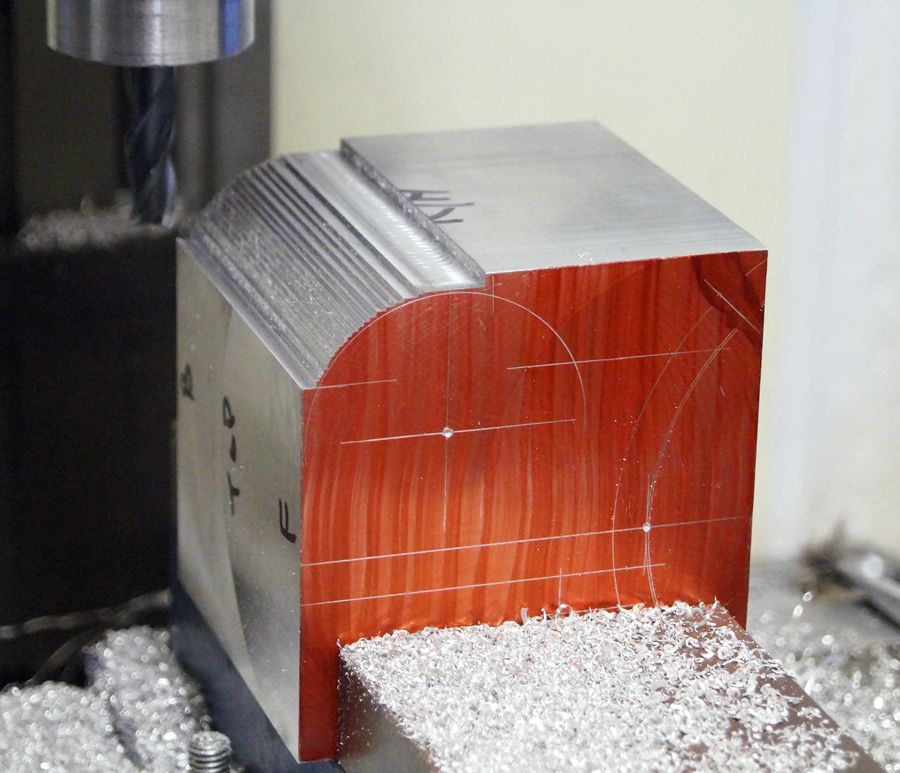

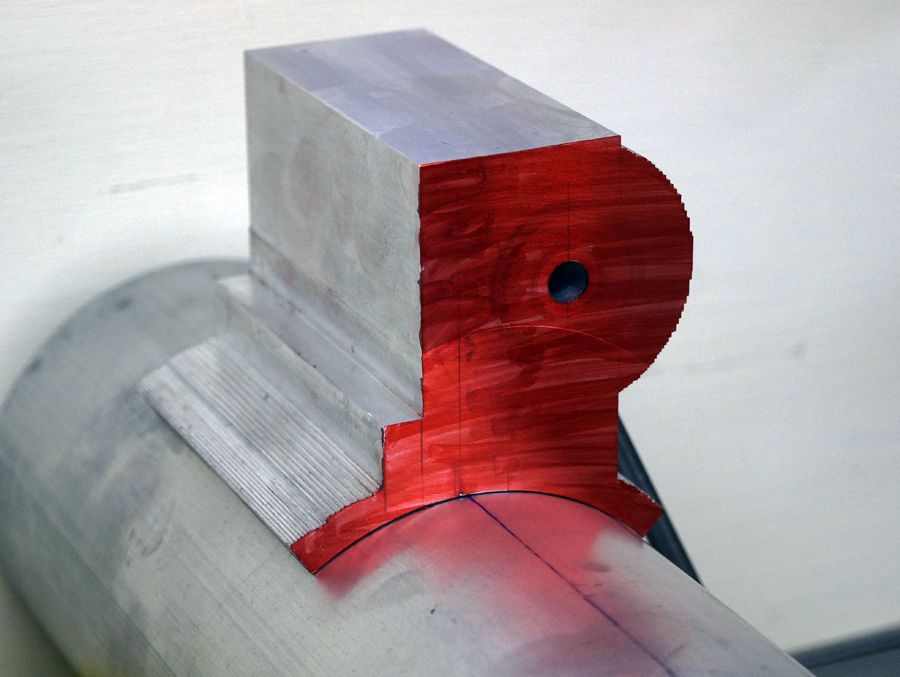

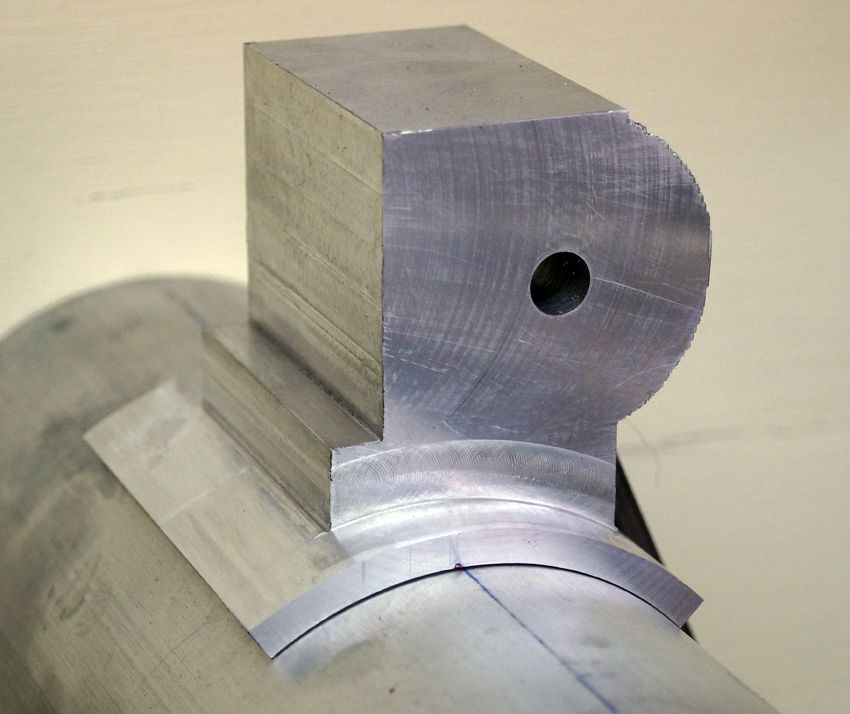

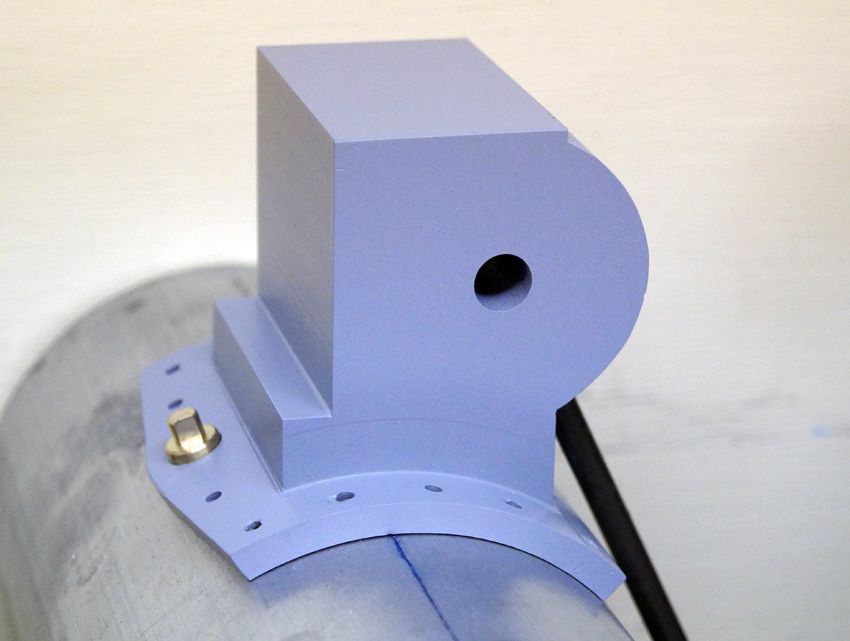

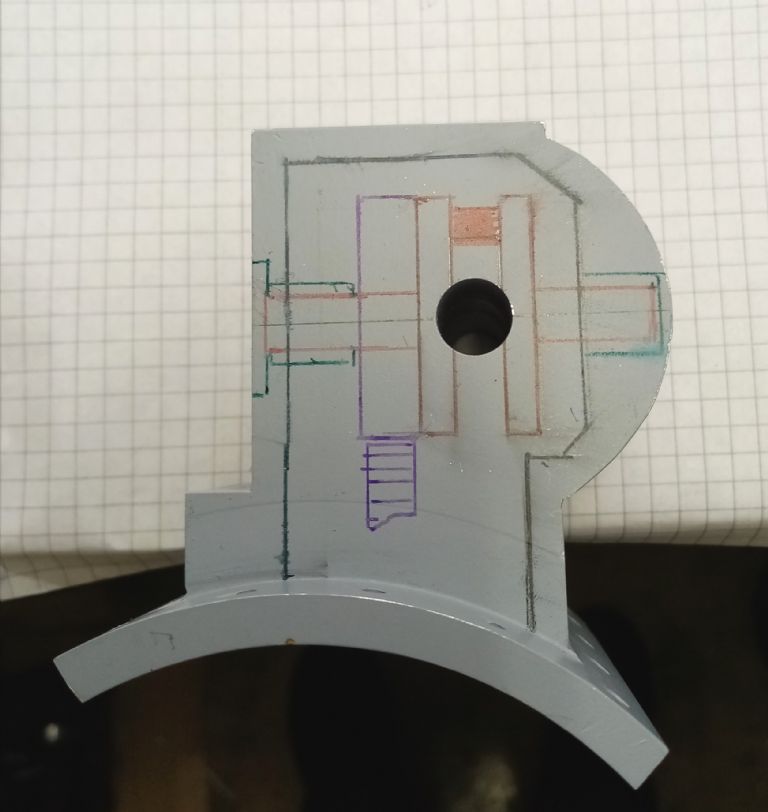

A picture below of the cylinder with an internal crank drive excuse the sketch on the end but it is just to give an idea. The black outline shows the cavity, the red the crank, the green plain bearings and the purple the toothed belt drive. It would mean the geared motor fitted in the boiler tube with the belt running through a slot in the tube up into the cylinder.

I must admit it looks a bit small when compared to the actual crank but the motor should be good as should the belt drive.

Don't know and as mentioned its off the top of my head so any thoughts welcome.

Edited By Ron Laden on 21/03/2021 11:05:47

Ron Laden.