Kiwi Bloke,

No offence was taken on my part by you mentioning Young's Modulus. I have you to thank for the Maximat Screwcutting Clutch design. You prompted me to take another look at the problem.

Young's Modulus is, as you rightly say, a Ratio of Stress over Strain. It's use in answers on this thread, sheds no more light on why the Plain solid boring is out performed by the pre-tensioned boring bar. If greater thought was applied to this problem we might be nearer an answer.

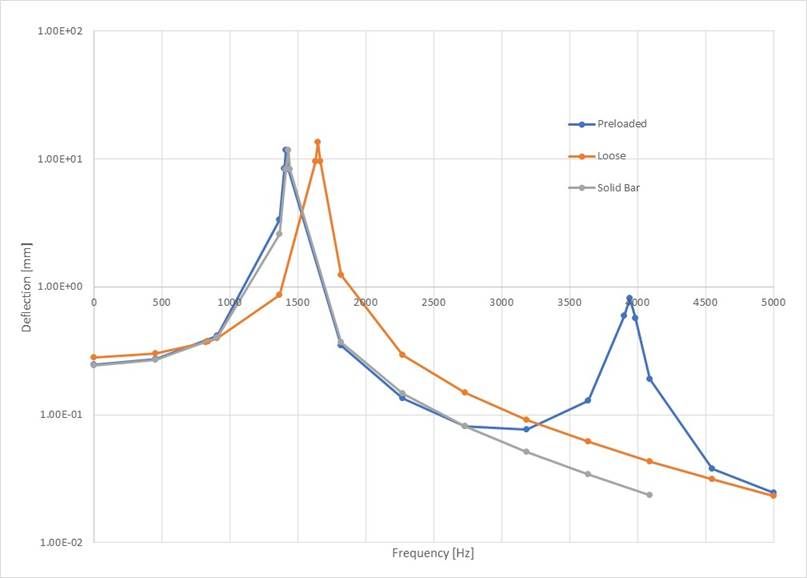

I too am struggling to understand what is going on, but I do like to see things through and by experimentation I have sorted in my own mind that the pre-tensioned bar is better. By my experimentation I have added values to a mostly theoretical thread.

Regards

Gray,

Michael,

I do not think your analogies were wrong, it sometimes pays to scale things up and look at the problem from a different perspective.

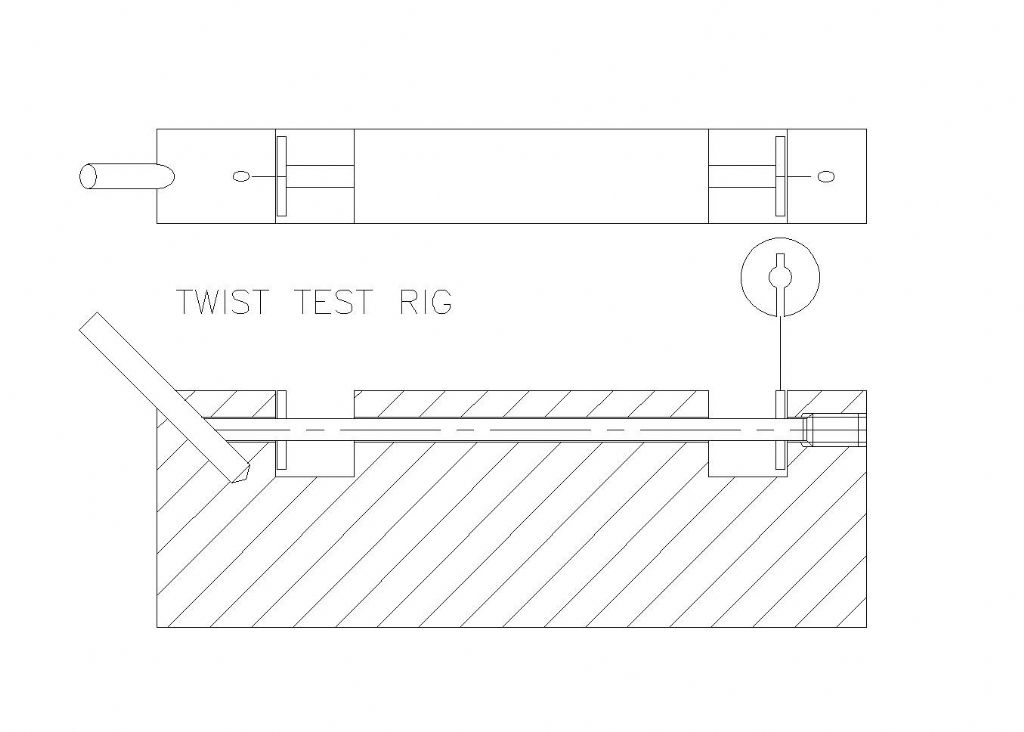

Like my example above with the wooden beam and the metal tie rods. The materials have not changed but the resultant structure is better. It is far removed from the boring bar problem, but the boring bar is just like the initial wooden beam attached at one end, that is to the tool post. Adding the push-rod changes the outcome, why it does escapes me.

As regards the FE analysis I hope you can draw conclusions from it, as it is all double dutch to me.

Regards

Gray,

Generally,

I received on Friday from a good friend an article by Martin Cleeve, Model Engineer 16th Sept 1966, pages 824-826. This, until Friday, was the first time I had read the article. I only started taking Model Engineer in Sept 1968, when I started my apprenticeship.

Martin's work is highly regarded by me, and many others. Thus it came as no surprise to me that his boring bar of choice was one using a push rod. His only drawback to using this type of bar was the need for the long drilled hole. He does however go on to describe a composite boring bar, part push-rod, part plain. That part I thought was a clever and an original bit of thinking. This latter bar does to a certain extent "put a stone in the ashes" on what I have been thinking. However he does say he could not see any difference between the bars in use.

The bars are threaded together, and in his "Practical Test" he states he had the joint "purposely left only finger tight", while plunging a 0.135" wide cutter into a 1" bore at 145 rpm.

Thus this is something that I would like to know the answer to "what is going on" with these bars. As this "structure" is even more complex.

Regards

Gray,

Edited By Graham Meek on 23/02/2020 12:45:57

Michael Gilligan.

Michael Gilligan.