Posted by RichardN on 18/08/2017 20:43:40:

…

But is a boring tool a simple cantilevered beam with a vertical load? Under no cutting forces with a tool mounted in holder but not engaged I accept gravity tends to act vertically, but surely as one plunges into a bore, the cuttting load is initially vertically, but at the first hint of downward movement the shape of the bore will add an exponentially increasing side load… is this not therefore a torsional/rotational force rather than a simple vertical load? Or does the maths still work out the same…?

If you consider this a rotational force… and the inner compressive push rod is compressed by means of a helically inclined plane… will increased deflection created additional tension, and change the 'strength' or 'chatter resilience' or will the reality of amount of rotation be insufficient to be measurable…

My response to those questions Richard is a resounding 'don't know'. I'm confident that a boring tool isn't a 'simple cantilevered beam with a vertical load' because – as you say – the cutter is forced sideways into the work, and then pushed downwards as it cuts. On top of that, any chatter will drive the boring bar with an oscillating force. I have no feel for the scale of forces involved.

After unsuccessfully searching the web for info on tensioned boring bars, I've decided that they 'don't work'. There's discussion about 'static deflection', like bending under gravity, and 'dynamic deflection', that is vibration. In a boring bar the first is minimised by making it as stubby as possible; by choosing a rigid cross-section, and by making it from a material with a high modulus of elasticity. Carbide is MUCH better than HSS in this application. The second is minimised by 'tuning' the bar to dampen vibration. This involves something like a pair of loose weights inside the boring bar near the cutting end. The weights are separated by a rubber pad and the space filled with oil. This type of bar is superior – even essential for getting a good finish – when boring long narrow holes. They work, for example, by mounting weights inside the boring bar near the cutting end. The way they work reminds me of the dampening mechanisms used to protect tall buildings in earthquake zones – a suitably mounted large weight at the top absorbs the energy. This US Patent is worth a read. At the really expensive end, there are boring bars that detect and compensate for vibration using electronics and servos in the tool-holder. Mega bucks apparently!

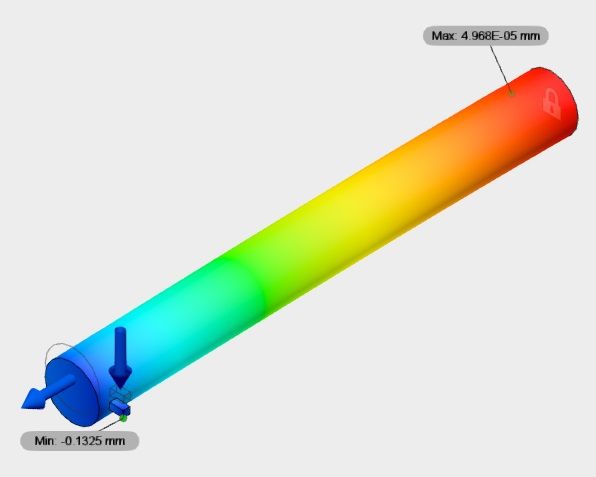

I think that a push-rod inside a boring bar is able to alter the frequency at which the bar vibrates. I'm yet to be convinced that the effect is useful. Using an internal push-rod to clamp the cutting in place is a good idea because it minimises the cross-section of the boring bar: it will fit into a smaller hole. That it also has an effect on tool vibration may have been exploited to boost sales.

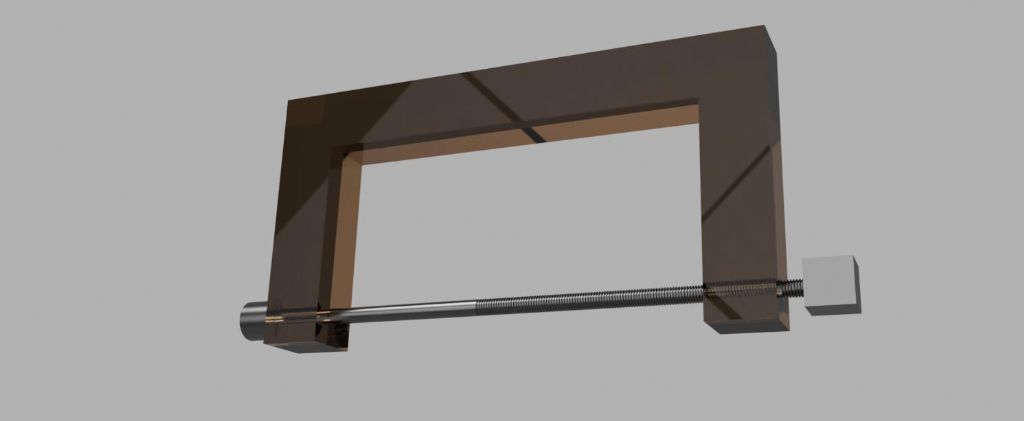

In other worries, Duncan criticised the guitar string analogy. That's lead me to ask if there's any difference between a rod tensioned with a push-rod, and a rod tensioned by pulling against a frame:

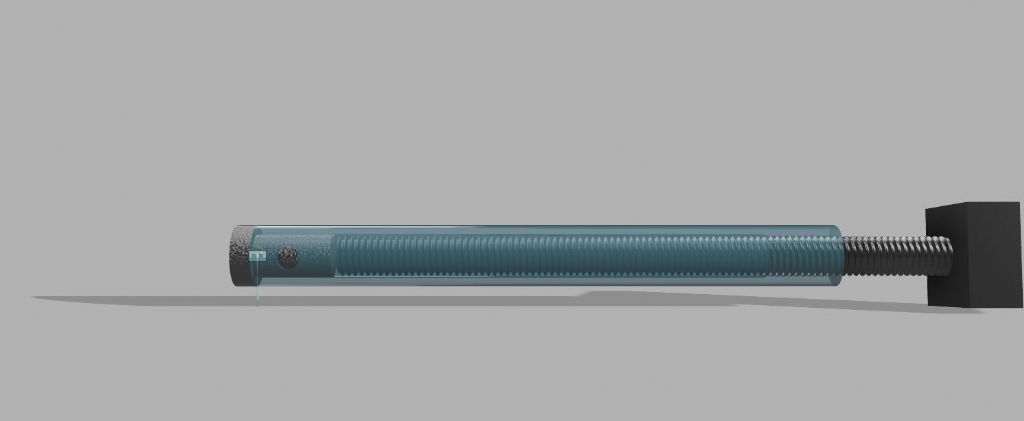

The rod is represented as a blue glass pipe in this Fusion360 picture so you can see the innards. Not very clear but the push-rod's thread is only engaged for 20mm at the right hand end. The blue pipe is stretched when the screw push-rod bears on the fixed plug on the left.

In this one, unscrewing the rod pulls it into tension against the frame on the left.

Dave

Edited By SillyOldDuffer on 19/08/2017 13:19:25

Michael Gilligan.

Michael Gilligan.