Posted by Circlip on 12/06/2017 11:45:25:

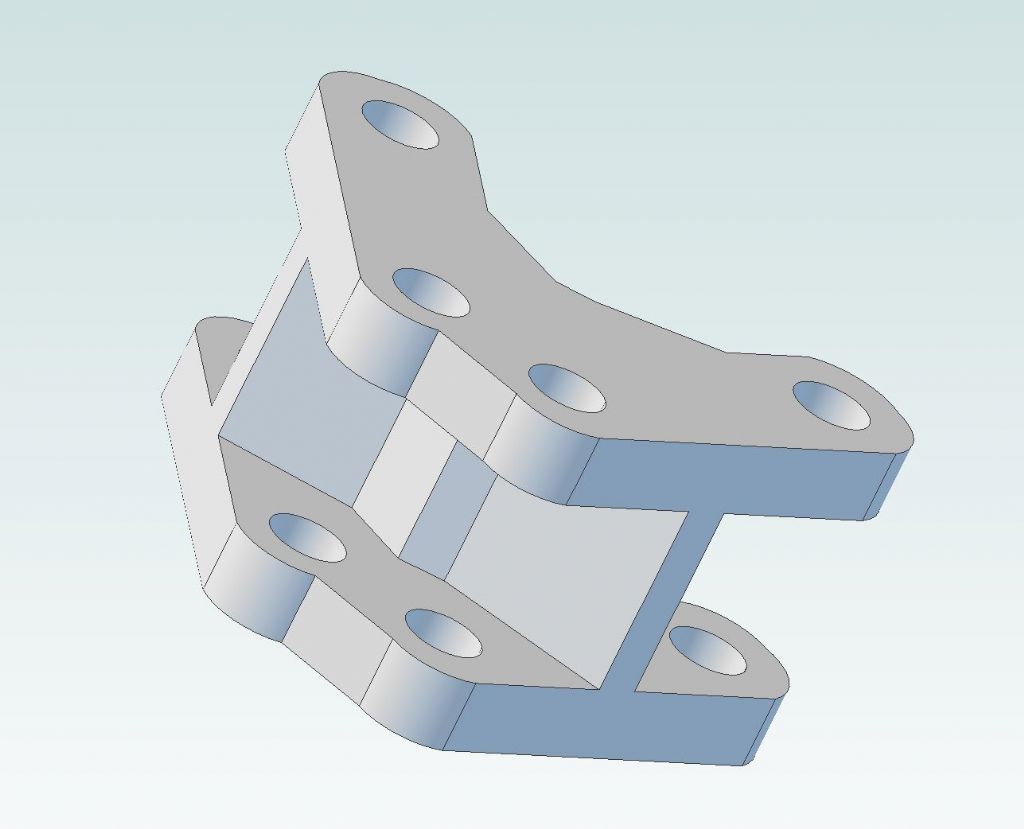

Can't see anything on the picky that can't be made by conventional methods John, Even the Pozi pan head bolts look like they could be bought.

The reason I 3D printed it was (a) vastly cheaper than using up loads of aluminium section and fabricating all the joints, (b) no worries about getting all the parallelogram bits the same size and (c) a very easy way of making a body to suit both the lens and the LED lamp.

A great example of the advantage of 3D printing was making a proper battery box. I wanted to fit in a standard lithium cell, a little charger board with a micro USB socket and use the switch out of the lamp used as a donor for the LEDs. It didn't take long to design the box so the board and switch clip in place, and the cell is held in place. There's a hole for the status LEDs to shine through (glazed witha touch of clear silicone). The box clips together, taking advantage of the texture of 3D-printed items (a useful tip) and the box itself clips to the base of the lamp.

If redoing it I might 3D print all the screws, you can go down to M5 quite easily.

Posted by Circlip on 12/06/2017 11:45:25:

' Spose since muddle ingineering has become a "What can I spend my disposable income on" 3D printers will become the must have. Is there a universal 3D printer component manufacturing measuring system? Metric or Imperial? No doubt whichever is stated, somebody will want T'other.

Regards Ian

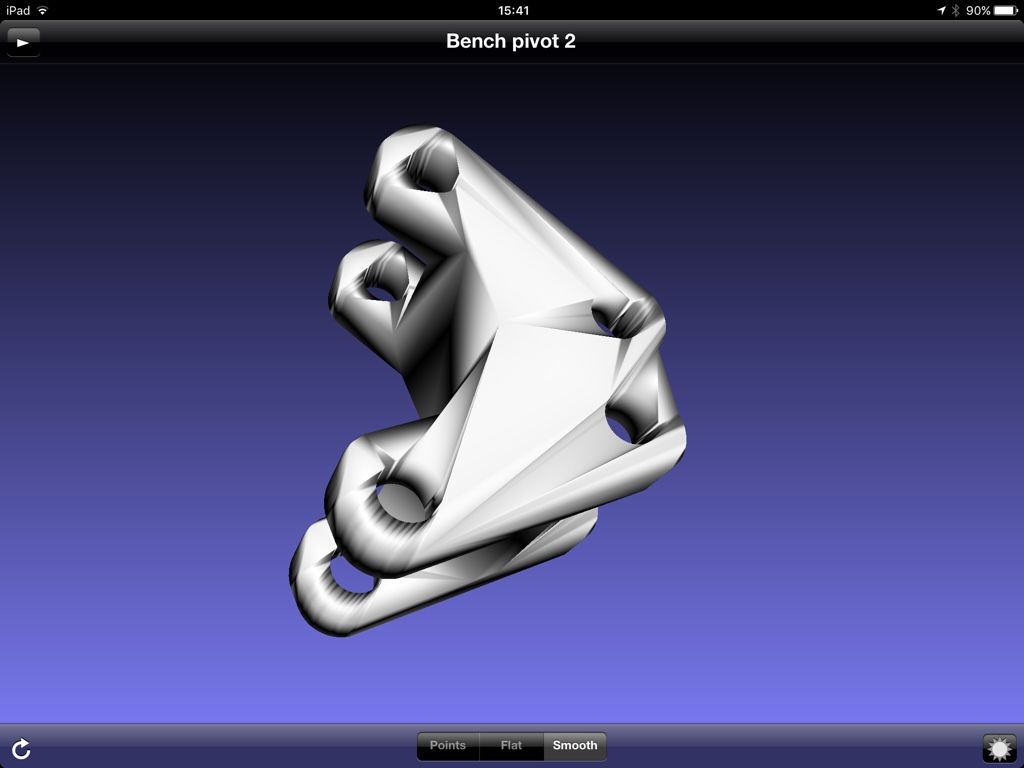

STL files just have measurements in 'units', I happened to design these in mm so if you use inches it will be rather big, the joy of 3D printing is you can scale things to whatever size you want.

Neil

Edited By Neil Wyatt on 12/06/2017 12:11:42

Enough!.