My attention was then turned to the cylinder head, I firstly skimmed the combustion side to give a stable base to sit it on in the mill to machine the various bosses.

It must be said that the casting was of excellent quality, it machined beautifully and gave no problems with material allowance.

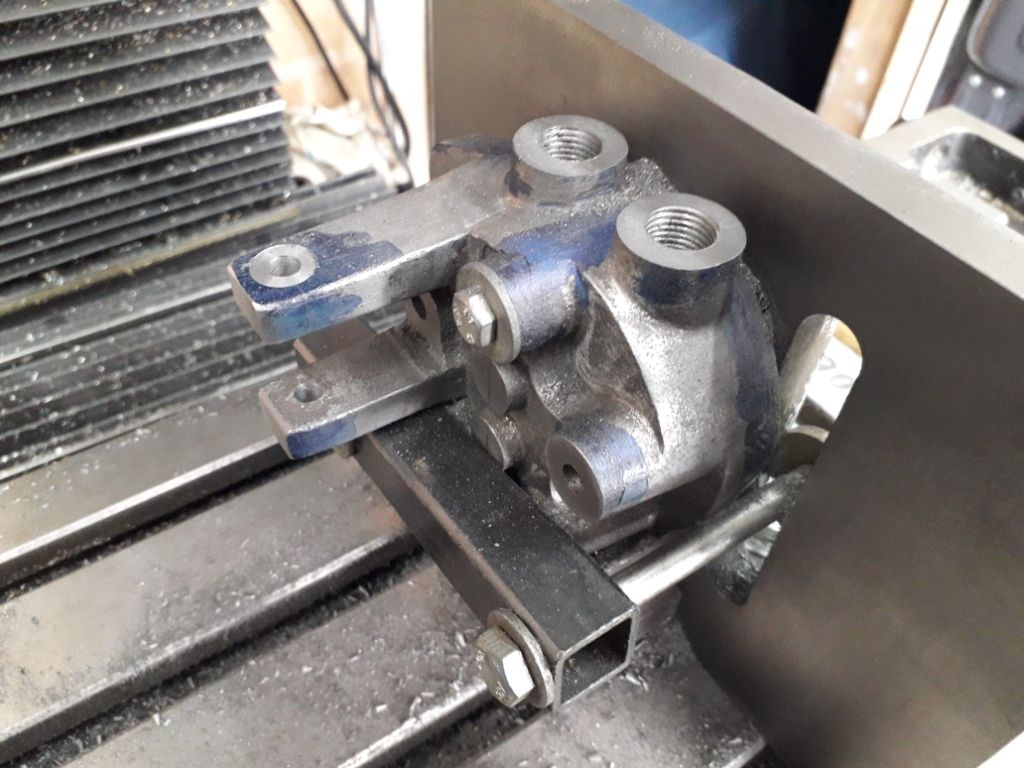

It was then over to the lathe to do the faces that mate to the cylinder and liner using the fixture I'd previously made based on what others have done.

I didn't machine the valve throats on the lathe, I found it was easier to go back to the mill and bore them on there, I used a 90 degree countersink cutter to form the valve seats..

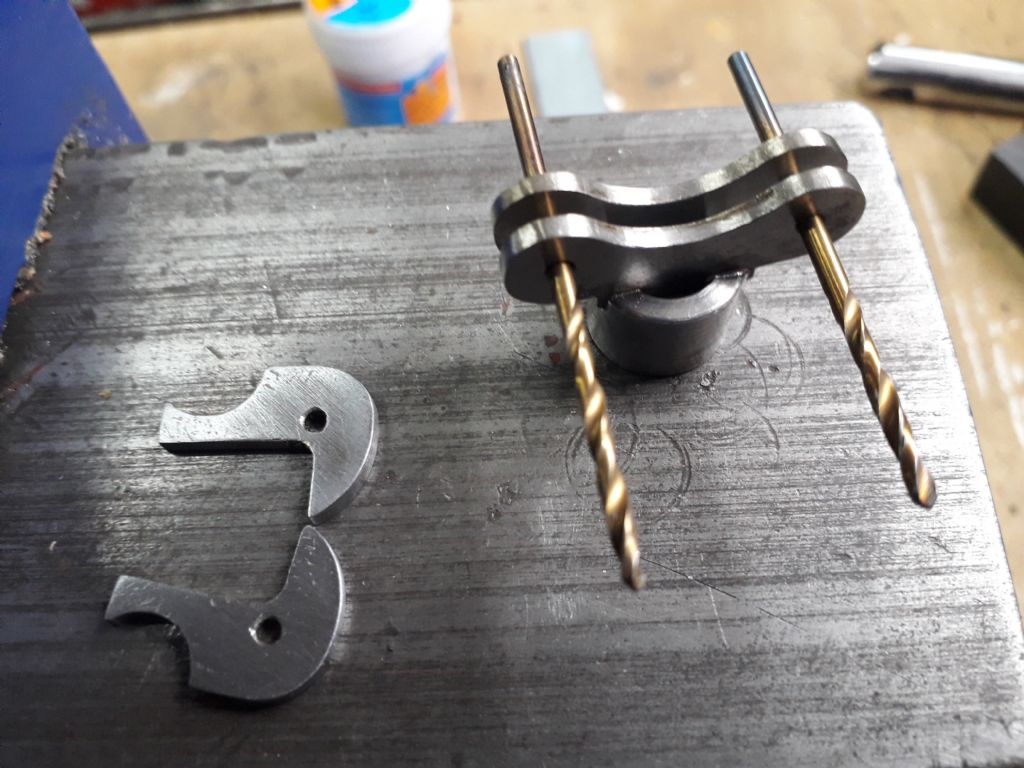

The valves were next in line, I turned the shaft end first. They were then mounted in a square Stevenson block set in the 4 jaw chuck that was set up using a piece of silver steel in the same collet that would be needed for the valve stem and the head end finished. I checked the first off against the seat in the head and it blued up a treat so carried on to the second.

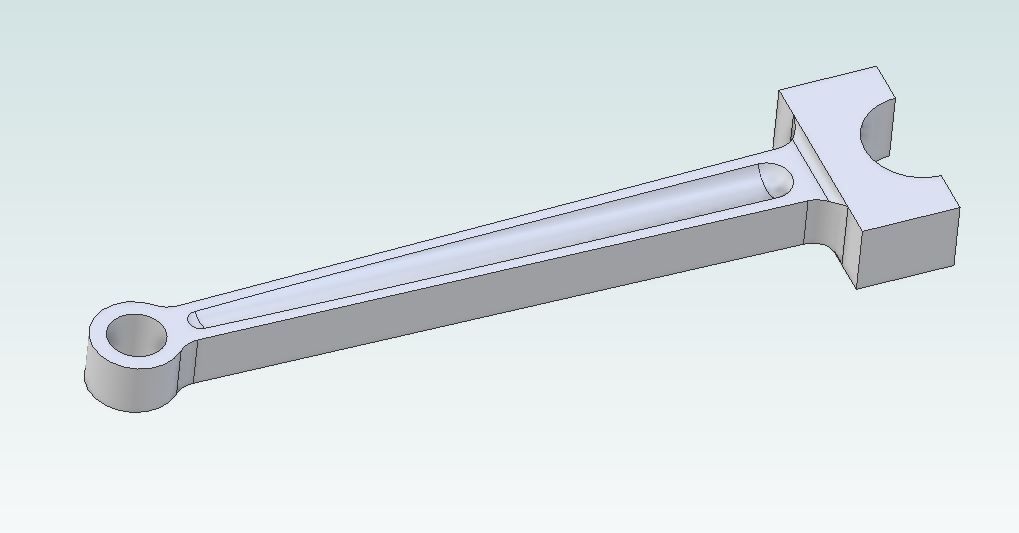

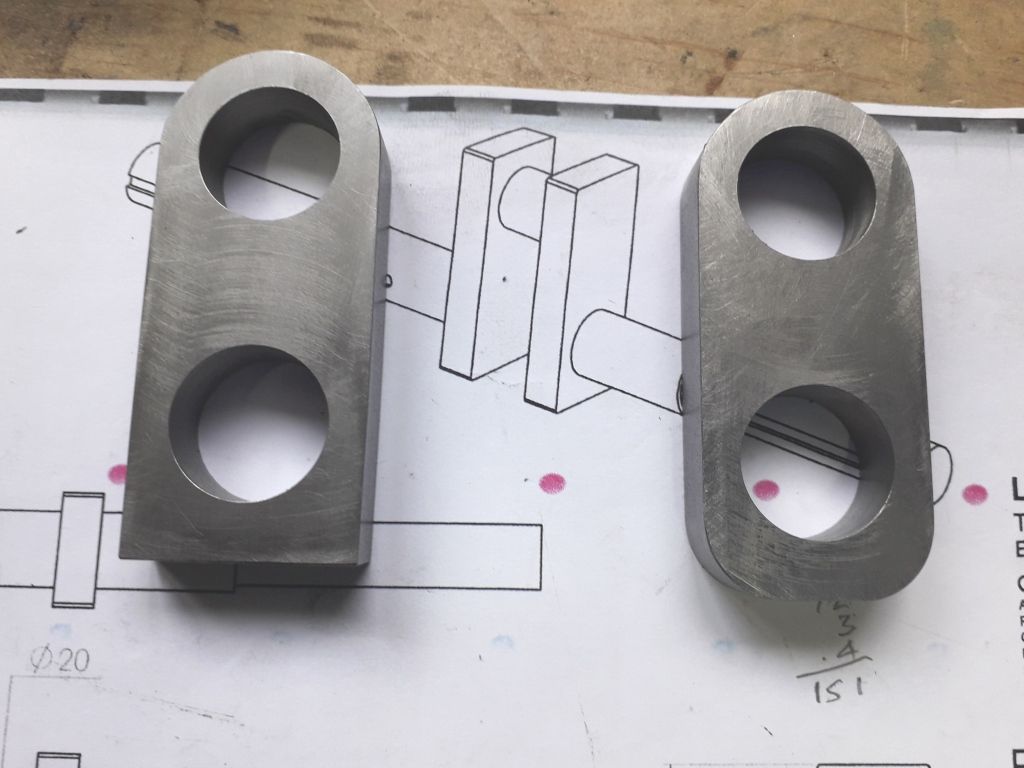

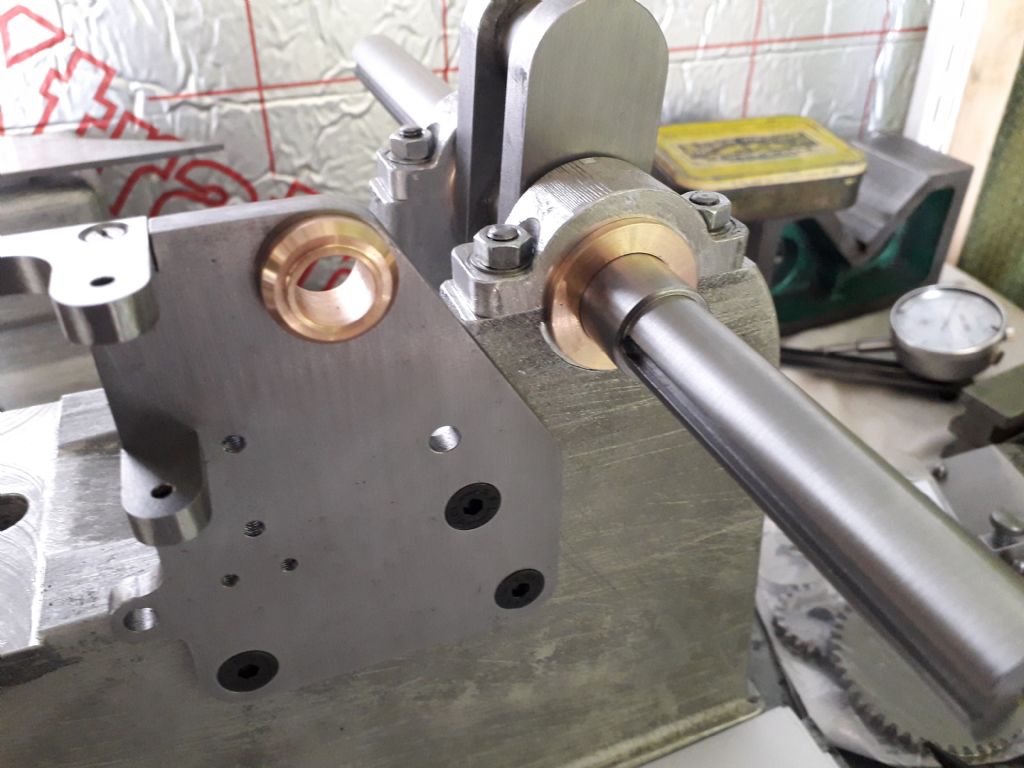

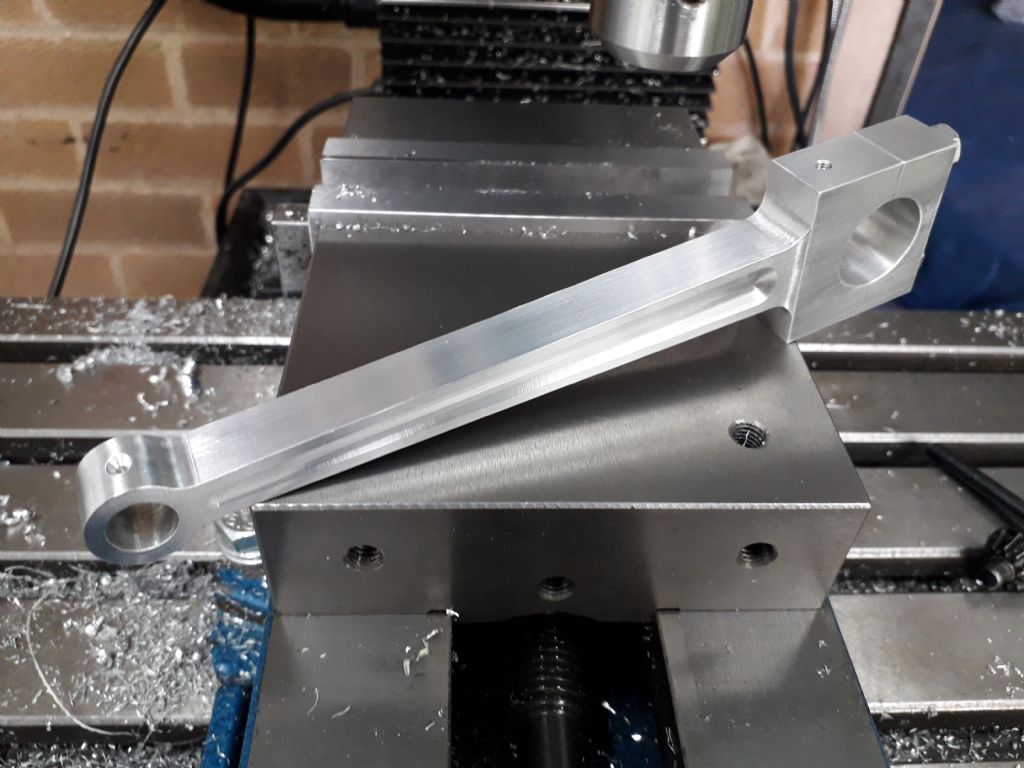

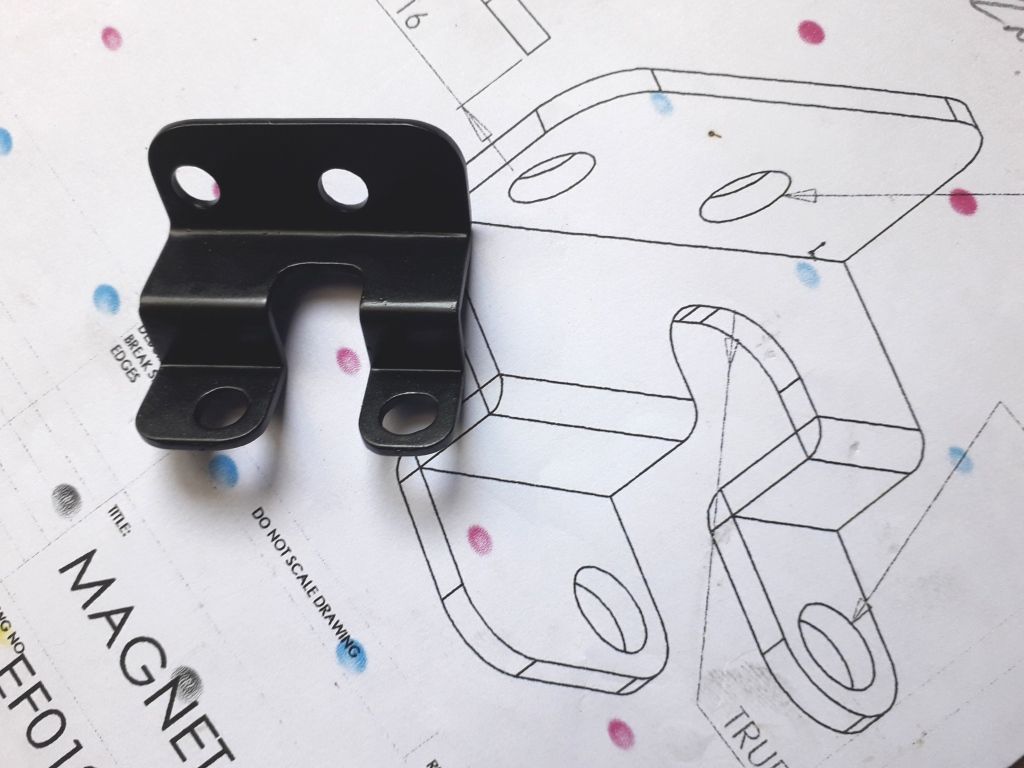

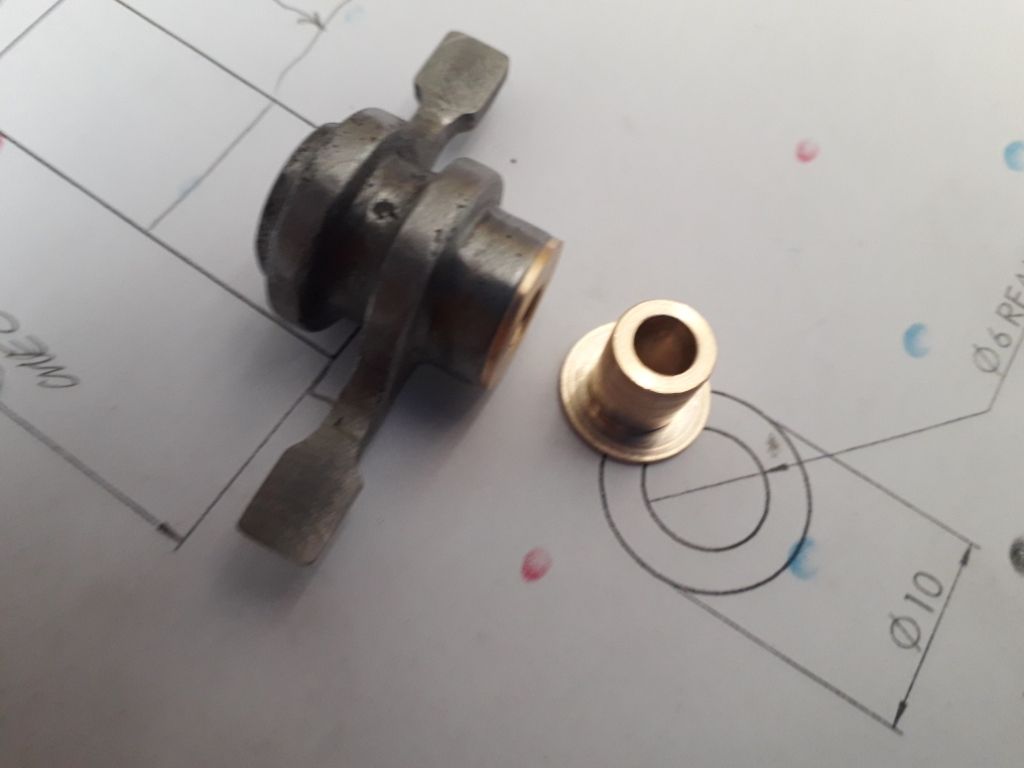

I had previously done some work on the rocker arm and it was now time to make the bushes. I deviated a little from the drawing as I felt it would be beneficial to have some bearing for thrust on either end, the drawing is for a plain bush that relies on the CI rocker bearing against the CI of the head, perfectly ok in this application but I felt this would be better. A top hat bush was pressed in from each end…

Of course a trial fit was in order. I guess I will need to think about a suitable paint for the head and rocker in due course…

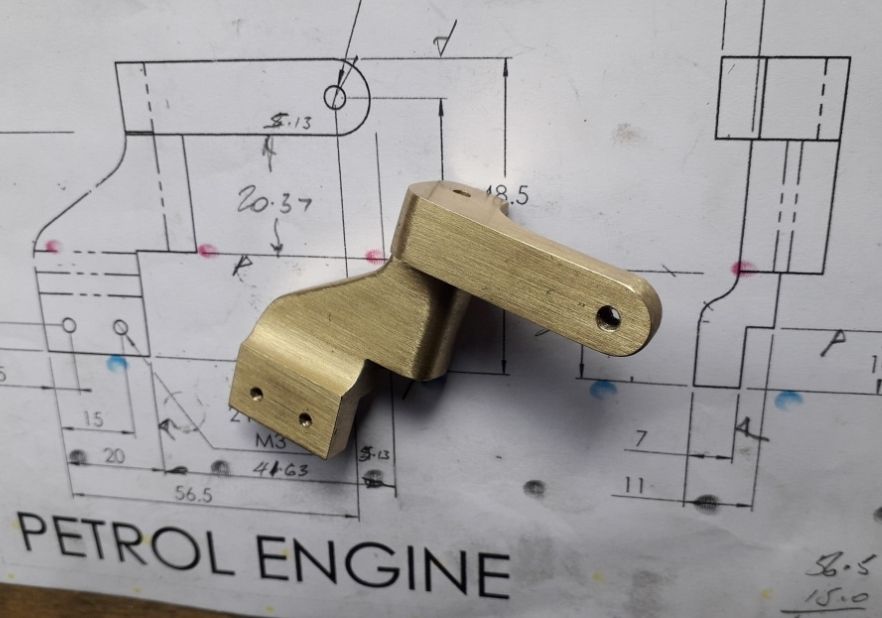

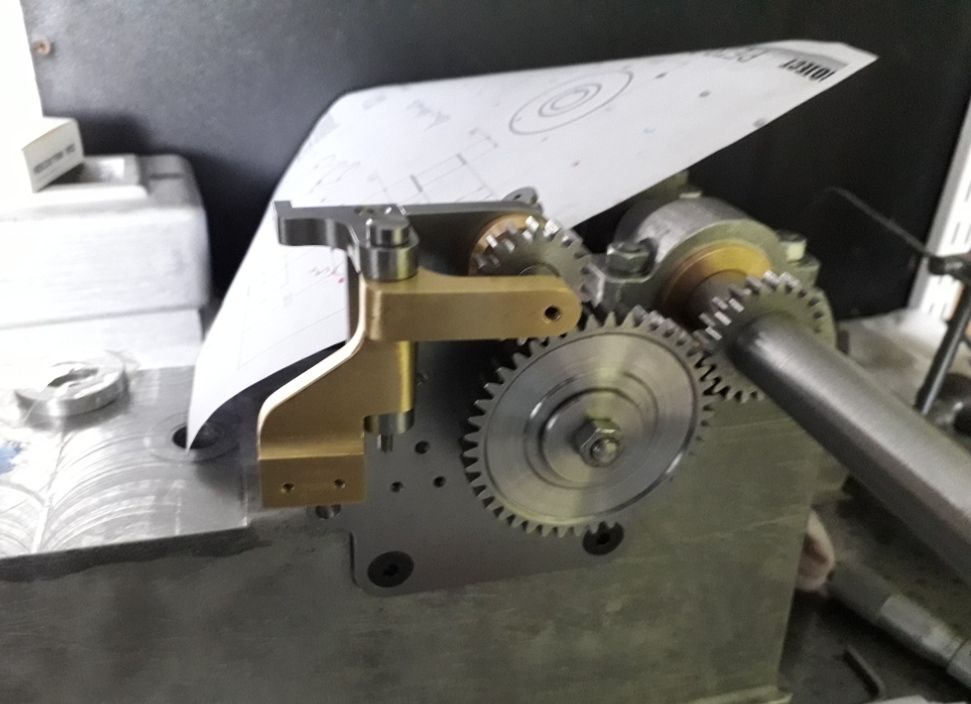

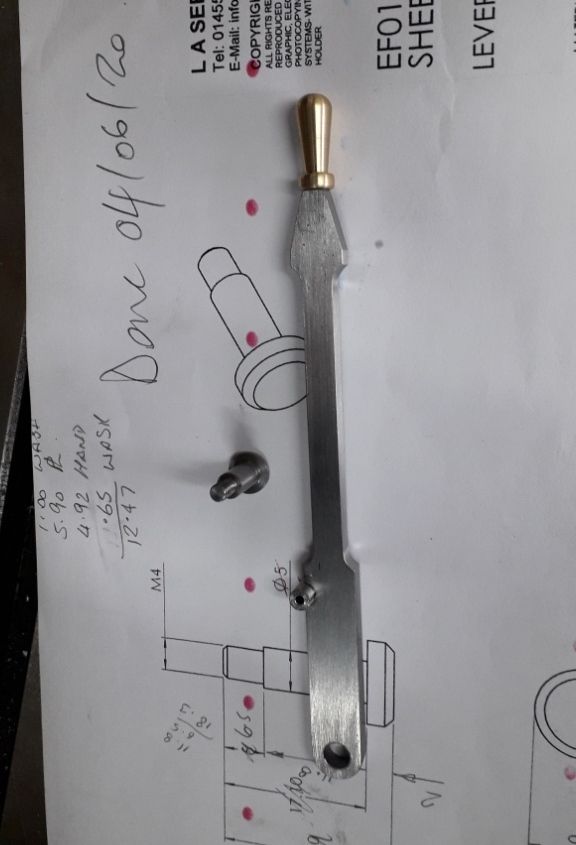

Back to the little bits again, this is the speed control lever, the little brass knob added a bit of bling!

I had planned to start on making the cylinder liner but the material (cast CI bar) that was supplied as part of the kit had some inclusions in, that is being replaced so will probably be the next job.

Robert Askew.