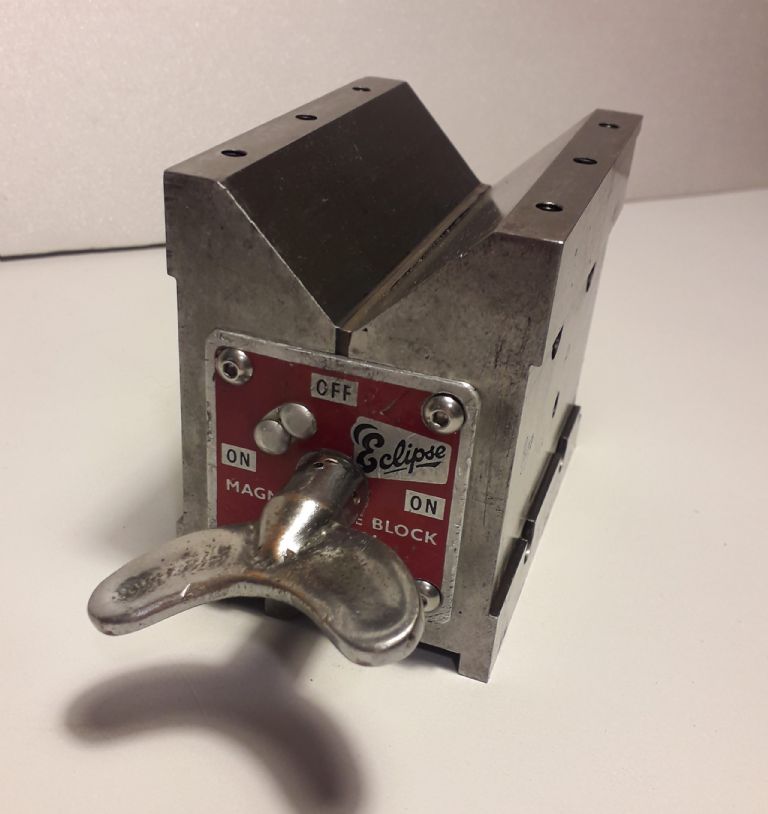

An update on this topic. I've spent the last few days making a new rotor for my V block. It seems to have succeded.

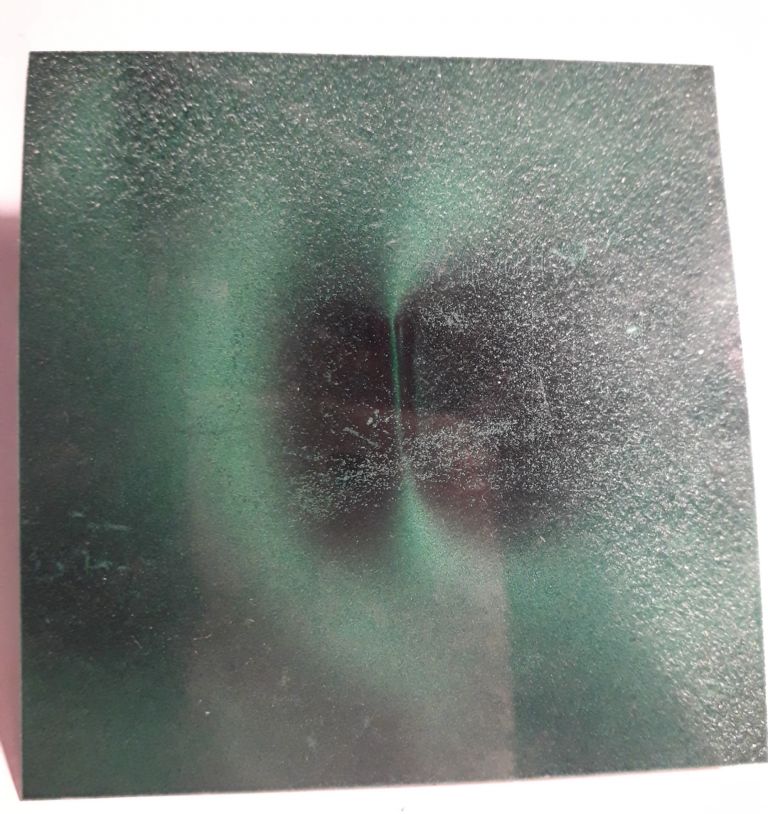

I glued (with Loctite 648) and screwed two surface ground lumps of steel to a milled block of aluminium. Mounted the assembly with a Myford dividing head on the milling machine and roughed off the corners. The reason for using an MT2 drill chuck rather than the three jaw lathe chuck was that the lathe chuck fouled the milling chuck.

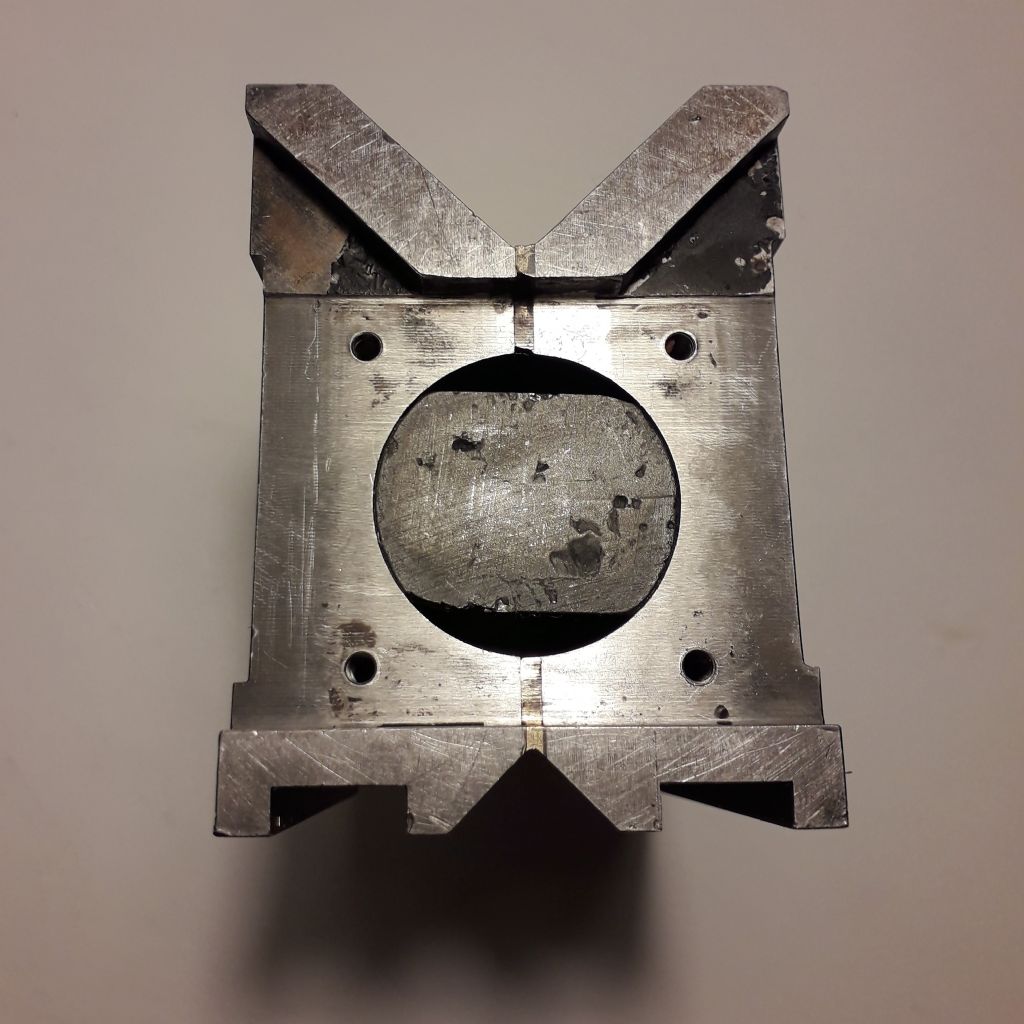

This is what the innards look like. It wasn't an intentional dissassembly, I got it a bit warm when turning is on the lathe with a chipped insert and the glue came apart. But it does show the general arrangement.

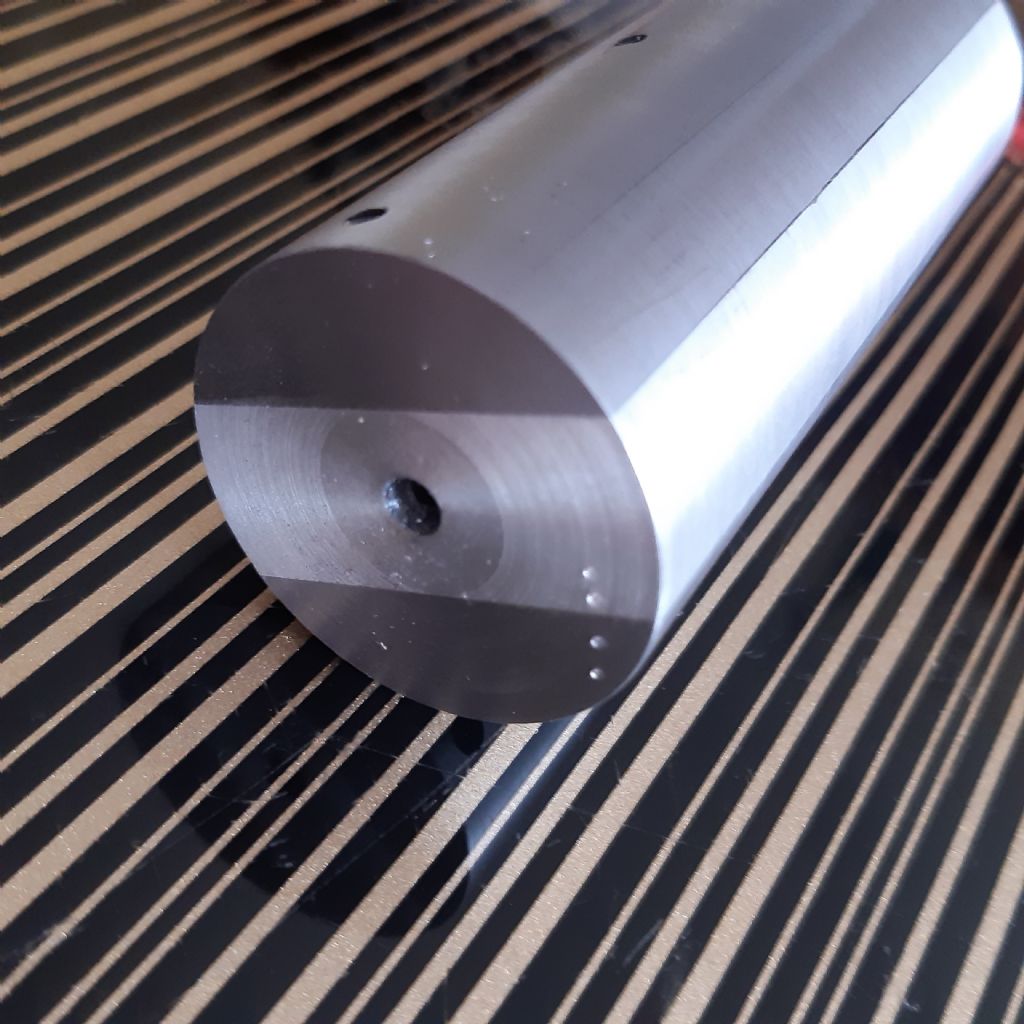

This is the finish turned rotor.

I match marked the ends with one dot at one end and two at the other to simplify reassembly

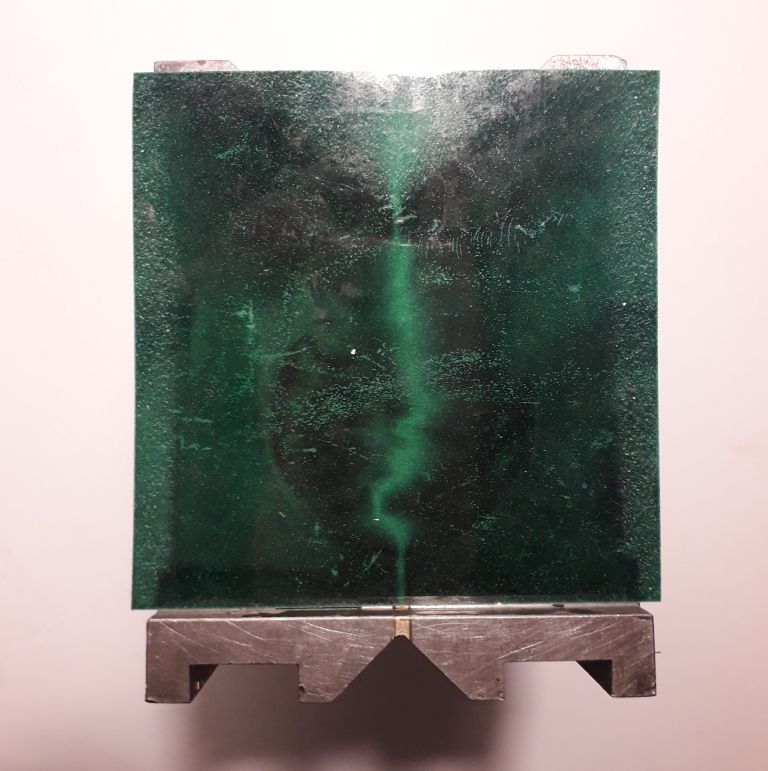

After cooking it in the oven to release the Loctire, I cleaned it up and reassembled the bits. This took some care, the 30x30x15mm magnets are extremely strong and want to sit on top of each other, not side-by-side. I actually used the bit of wood, clamped with two, distanced, G cramps to sit over the first magnet while pushing the second magnet into its pocket. The edges of the steel pole pieces are also razor sharp and need respect. More Loctite 648 was used as glue.

At this point I learned that it would have been better to use a taper reamer in the screw holes before separating the parts, so that they could be accurately realigned with a couple of taper pins. I had to turn a couple of thou off the assembled rotor to get it to fit in the V block. Not a nice thing to do with a strong magnetic assembly.

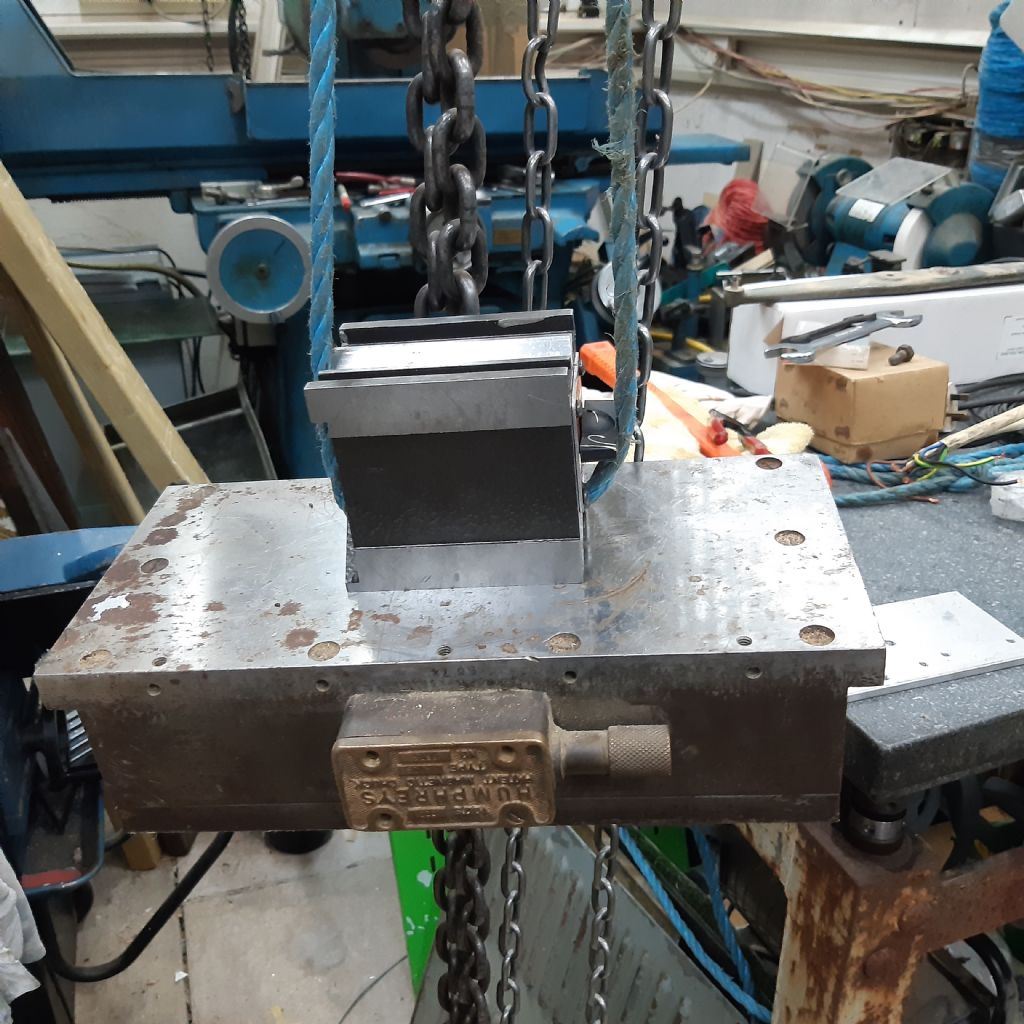

After getting it all together I gave it a little test. It happily holds up a 27kg electromagnetic chuck. With the original magnets, I could pull the V block off with my hands.

Edited By Mark Rand on 13/03/2022 12:45:52

Massimo Dalmonte.