Have just watched Stefan Gotteswinter's video – thank you for the link, Mike.

Very interesting ideas, not just in the drilling, either.

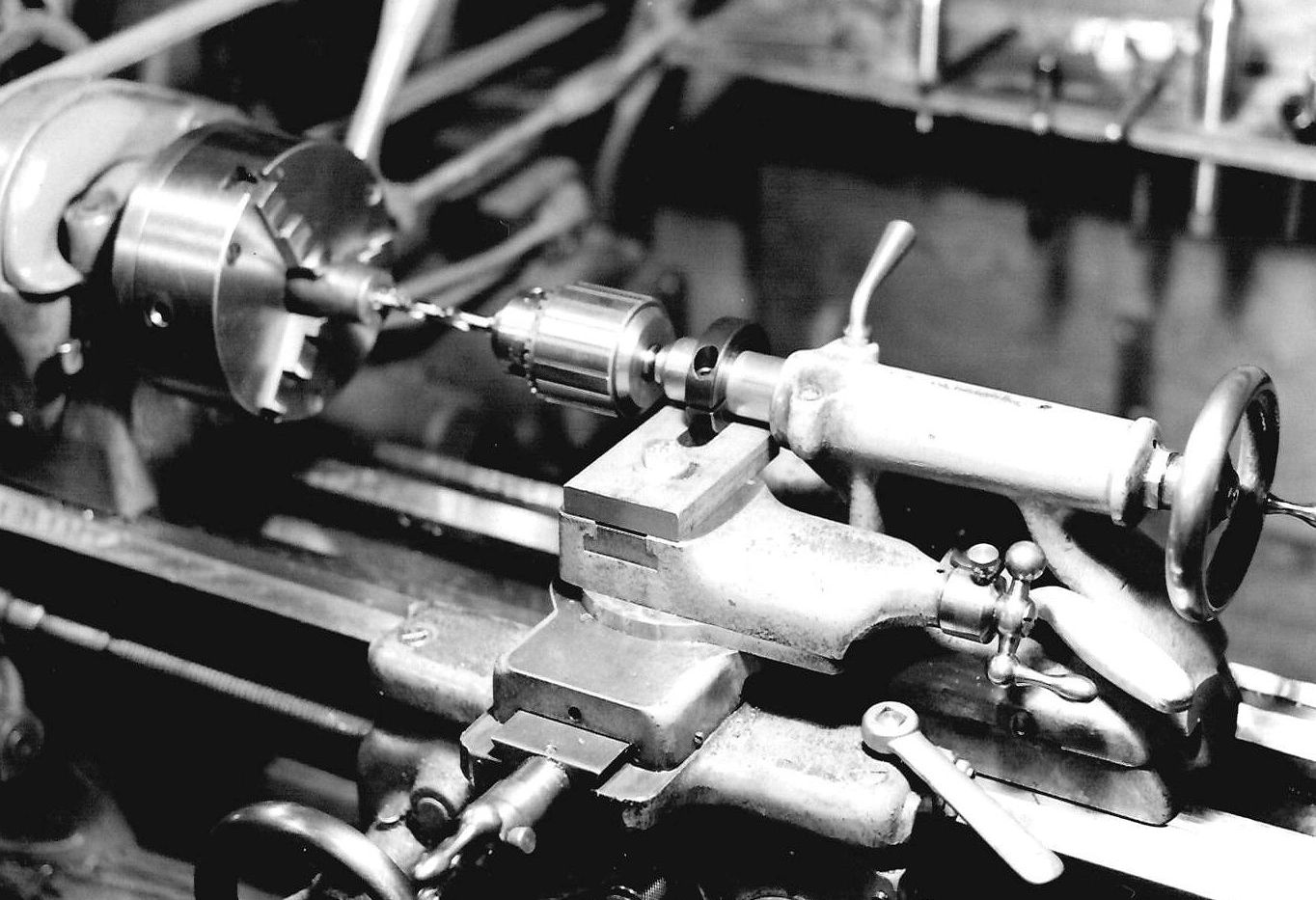

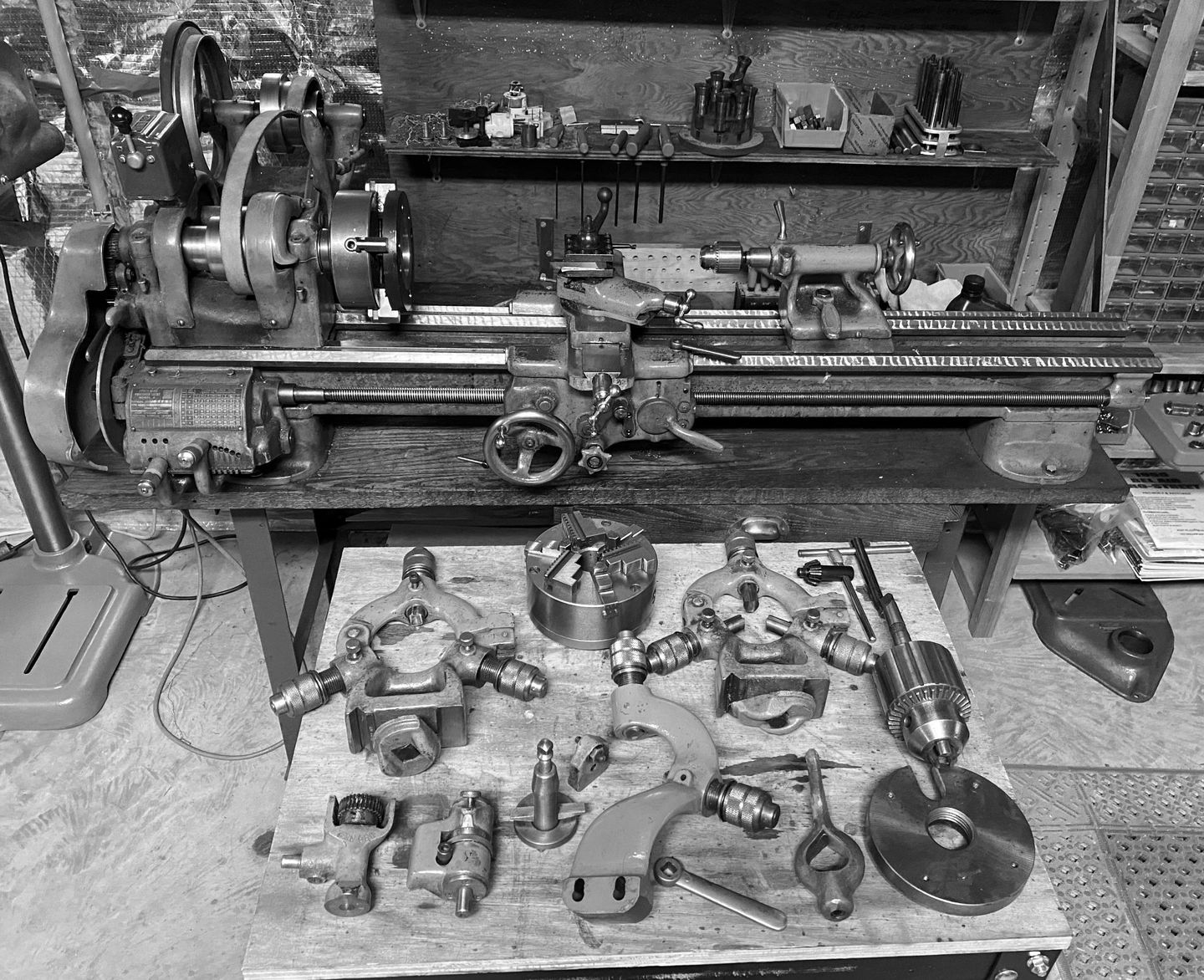

I had pondered the feasibility of a chuck-holder held and driven by the saddle but located directly by the bed, obviating having to align it every time. Using the saddle to pull the tailstock along sort of does that, but you've still the problem of a long overhang, especially with short drills, for the drill even to reach the work.

I must admit a 6-jaw chuck is new to me. I might vaguely have heard of them but never seen one in the metal, so to speak.

He says a centre-drill is wrong for spotting. Well, I won't argue with that, as it's often said by model-engineers rather nearer the Gold Medal than I'll ever be; but this does seem a recent development, and I don't recall seeing an explanation why they are fine for their named use but not for starting a drill.

Regarding his counter-sinking the hole before tapping, assuming sensible metal depth I usually counter-drill to nominal full diameter to just below the surface, one to two thread turns worth. I still lightly chamfer the edge.

0.2mm drills….. I worry about whopping great 2 whole-millimetres…. (Like last night, in the bench-drill, making split-pin holes across 1/4" dia steel.)

Hopper.