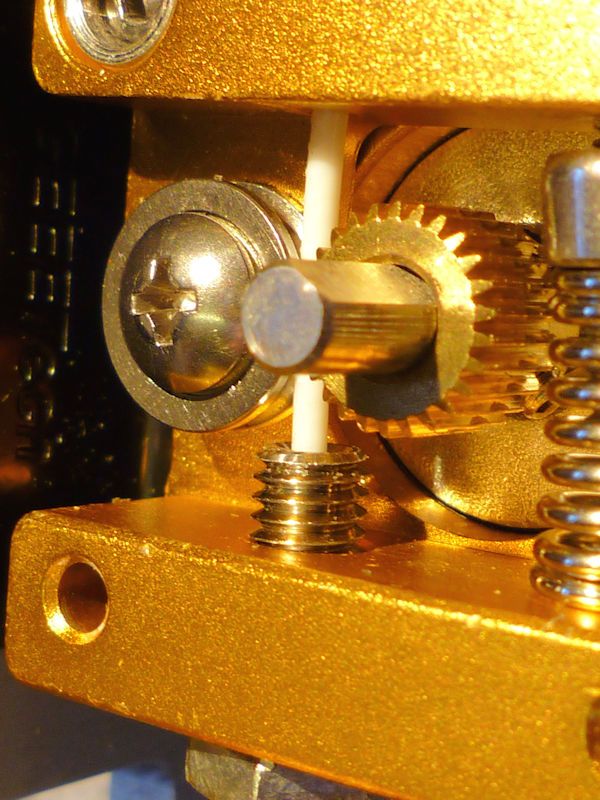

Some time ago, I printed a little guide in the form of a convex-sided wedge with a central hole, that guides flexible filament to the heatbreak tube of a Mk8 hot end.

There are various versions on thingiverse, none of which fits as-is but some can be cut down to make a good fit.

I've since done some experimentation and the reliability can be greatly increased by fitting a short length of heatbreak above the normal heatbreak to ensure a continuous path from the feed rollers to the nozzle.

The great benefit of this come when changing filament. Set the hotend to a suitable temperature, cut the filament (nice and squarely) close to where it enters the Mk8 then tell the extruder to extrude about 40-50mm of filament. Once the filament has cleared the wheel you can manually release the sprung roller and pop in the new filament, without any fiddling, until a bit of ooze comes from the nozzle. If changing colour now feed until the new colour runs true and you are good to go.

This is MUCH easier than the hit and miss of pulling out hot filament hoping it won't snap or get stuck and it also makes threading the new filament easy instead of rather fiddly.

I've done this several times with PLA and today I changed from PLA to nylon with no problems at all, although it did take a while for the PLA to clear.

Neil

Muzzer.