Well, thank you all for that vote of confidence, very much indeed. I guess I’ve now got to live up to it.

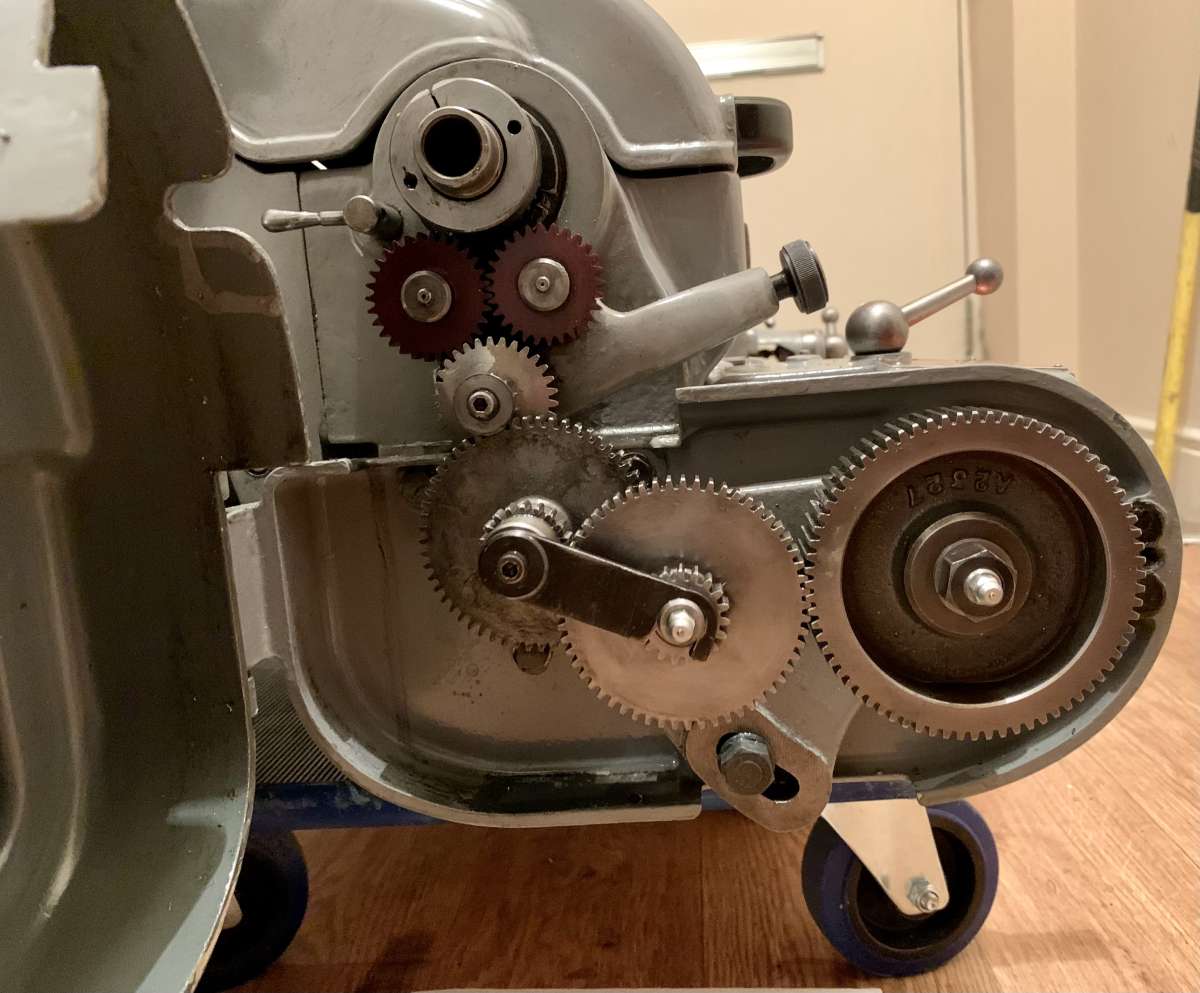

I think the answer is actually quite simple. If you take the QCGB out of the equation you’ve now got just another lathe with an 8 TPI leadscrew. Back in the day before I bought a gearbox I used change wheels as did everyone else, and thereby needed a range of wheels and a bit of arithmetic to make the gear train do what was needed.

My recollection is that a set of standard change wheels for the non gearbox application consisted of one each of the sizes 20, 25, 30 etc by 5’s up to 65T. Here’s a copy of the reason why:

xxxx

That’s taken from the back cover of this document:

I had an ML1 at this time – still got it – which I bought off a scrap man for £37 in 1979.

And you’ll note that this duplicates the information Brian has shown in his book. Table 67 refers though there is a 2:1 factor to accommodate because the Seig lathe imperial leadscrew is 16 TPI.

I dare say the same information is in the ML7/S7 handbook with the brown cover. I couldn’t lay my hands on that though I’m sure I’ve got one somewhere. Note that the metric trains only need the same set of gears, though two 20’s are needed to get something pretty close to 1.00 mm pitch. I seem to remember buying a 21 T gear for something to do with the metric set-up, but the why is lost in the mists.

Hidden in this is the need to fit a 20, or a 40 or a 30 t wheel to the mandrel, which is why that keyed 30/x gismo labelled “Standard Idler Cluster” was included with the kit of parts above.

The 30/12 cluster was sold as a fine feed gear, it’s incidental that this same is needed to feed power down the gear train to the Mk1 gearbox.

Which doesn’t explain what the 24T (nor the 32) gear was about, but maybe we’ll come back to that.

Brian Wood.

</p>

</p>