Posted by Robert Atkinson 2 on 10/05/2019 07:47:43:

Posted by Nicholas Farr on 10/05/2019 07:04:08:.

…

…

If the KDJ 17 is so reliable why are there so many being sold? There are dozens just on ebay, they are not all for new build machines.

The bigger problem is the NVR contact is not failsafe. The only force opening it is a spring. If the spring breaks, coil armature or sear sticks or the contacts weld there is no force to break the contact. A properly designed E-stop has forced break contacts.

…

Robert G8RPI

Bit of false logic in 'If the KDJ 17 is so reliable why are there so many being sold?' : Robert draws the conclusion that they must be unreliable because 'so many are being sold'. That might be true, but there's no evidence for it. We don't know what the size of the market is for these switches, or their failure rate. But the real killer is that we don't know how many are being sold, we only know that they are being offered for sale. If Robert's logic is correct, then it also applies to the entire RS catalogue!

I agree though that these NVR switches aren't fail-safe. But for exactly the same reasons neither are the contactor circuits used in most machine tools.

Problem with fail-safe systems is that covering every contingency, however unlikely, rapidly gets complicated and error prone. In this case, we are reducing a workshop risk, not preventing a second Chernobyl. I suggest there's a hierarchy of measures that could be taken:

- A fused machine is safer than an unfused machine. (People do replace fuses with paperclips…)

- The correct type of fuse (or circuit breaker) is safer than the wrong type of fuse (fast-blow, slow blow etc.

- A switched machine is safer than an unswitched machine because it can be turned off in an emergency. I suggest steps 1-3 are the absolute minimum.

- An NVR switched machine is safer than a plain switched machine because the machine won't restart automatically after a power cut. I suggest this is well worthwhile.

- A machine fitted with a prominent easily reached Emergency Stop switch wired to disconnect the entire supply is safer because the machine can be stopped quickly, even by someone who knows nothing about the machine. I suggest this is highly desirable.

- A machine fitted with safety interlocks on guards, end-stops, and doors etc is safer because the machine stops when the operator does something unwise. Whether or not this one is applied depends on the risk. However, it's not usually desirable, or safe, for small interlock switches to interrupt the full power applied to the machine. Instead, they are wired to control a contactor, or the NVR switch.

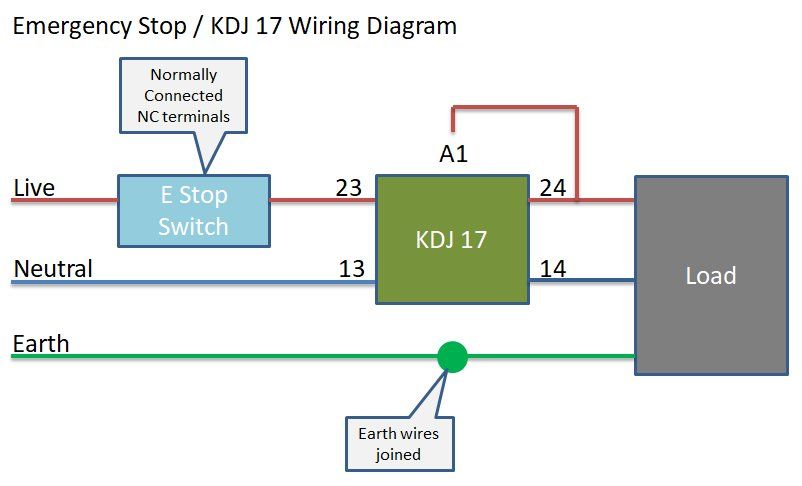

For what Grant is doing, Andy's circuit seems entirely appropriate to me:

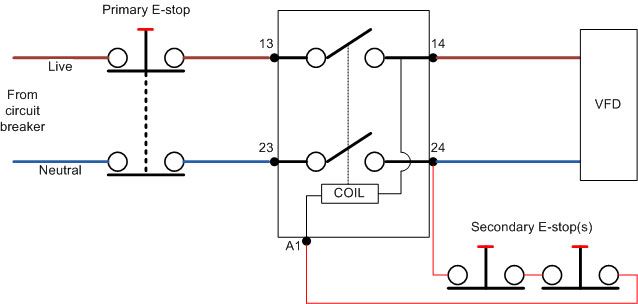

And if Grant has secondary requirements to cut power, like protecting a door, putting extra switches in the A1 to 24 link wouldn't be insane. However, I wouldn't use a KDJ17 like that if the secondary switching was frequent because it's unlikely that a cheaply made NVR will take a lot of on/off cycles. For multi-repeat switching a contactor is a better bet.

My experience of safety interlocks is in software, where I learned my second favourite adage: 'Fail-safe systems fail by failing to fail safely'. The best advice is 'Never meddle with gunpowder by candlelight'.

Dave

Robert Atkinson 2.

Robert Atkinson 2.