Hello chaps,

Nice to see the Drummond fraternity is here too.

I’m afraid that you are mixing your models and ages.

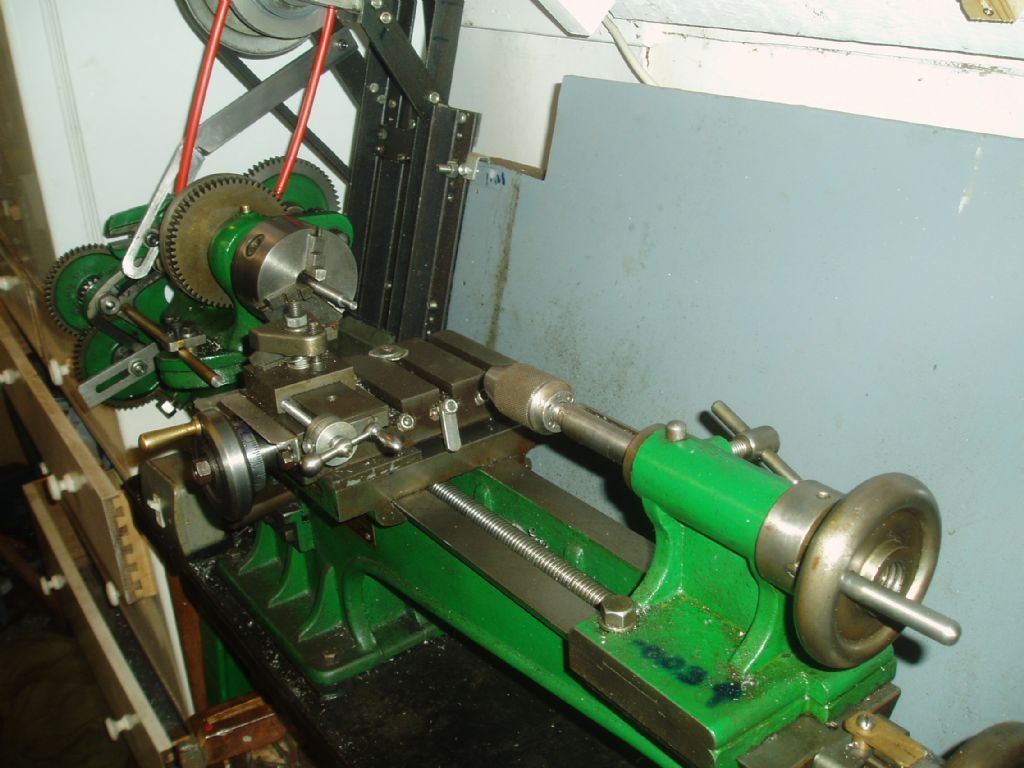

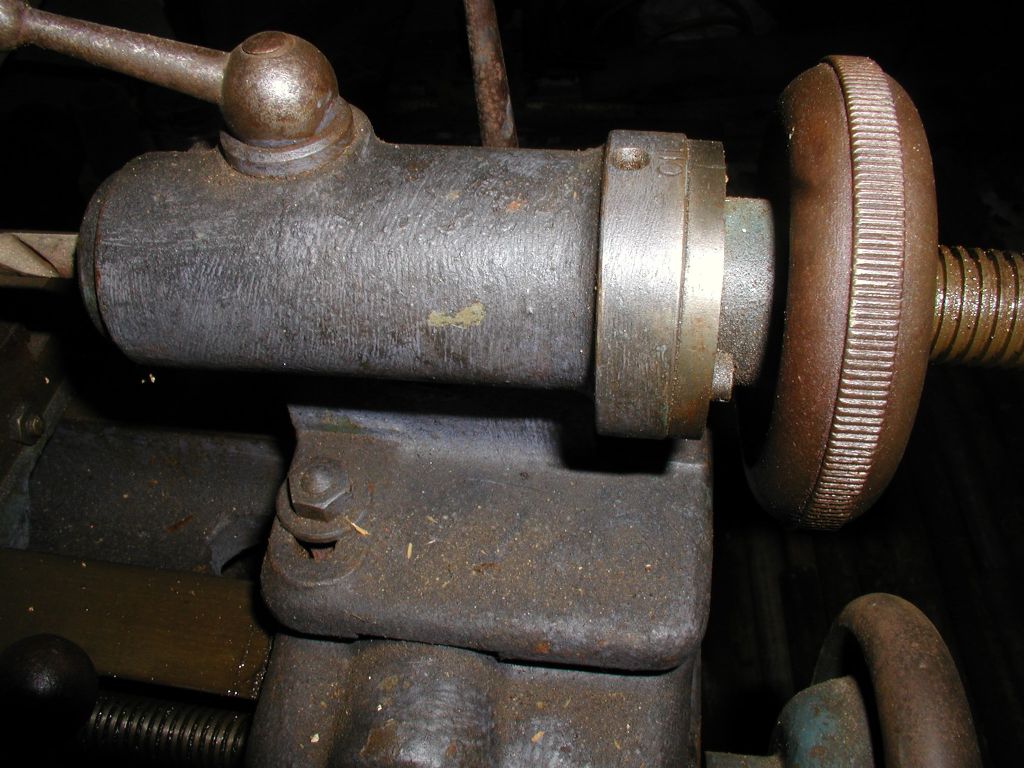

Nobby’s is a 1903 – 1912 model, commonly known as a Pre A type. This was the first full production model of the 3 1/2 in flatbed lathe. It did not have a designation, but earned the Pre A type name when Drummond brought out the A type Roundbed in 1908.

Ady’s is a 1925 – 1940s M type.

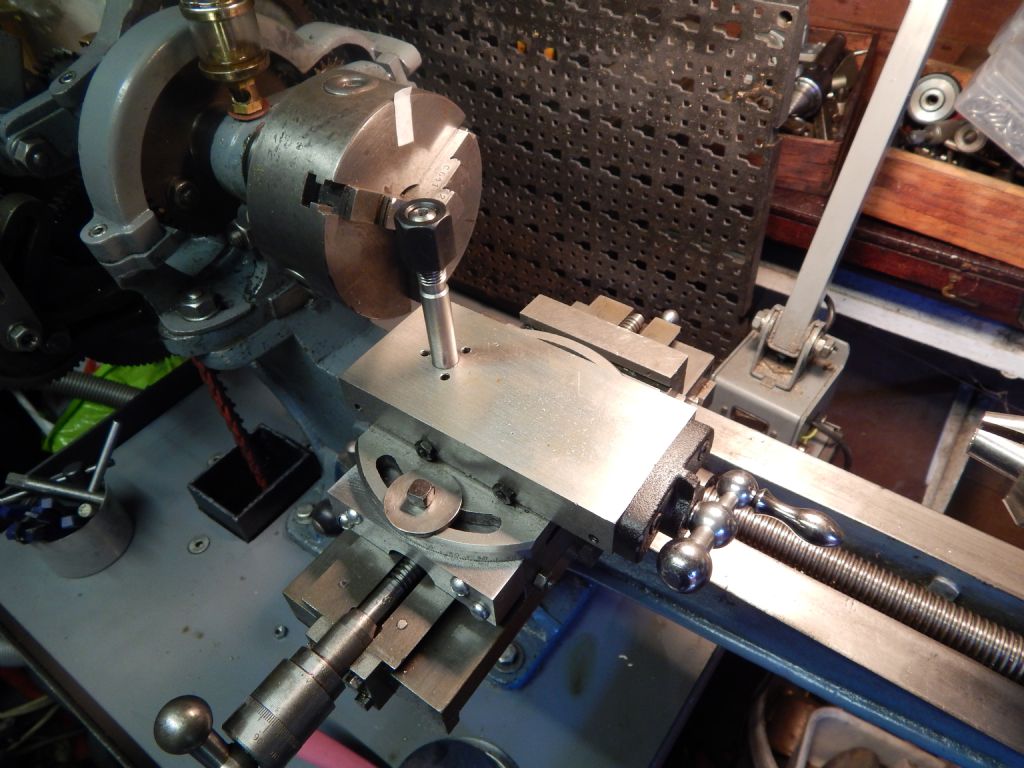

In 1912 Drummond brought out a new model lathe, completely different to the previous Pre A type. This was the B, recogniseable by the strengthening loop casting on the headstock.

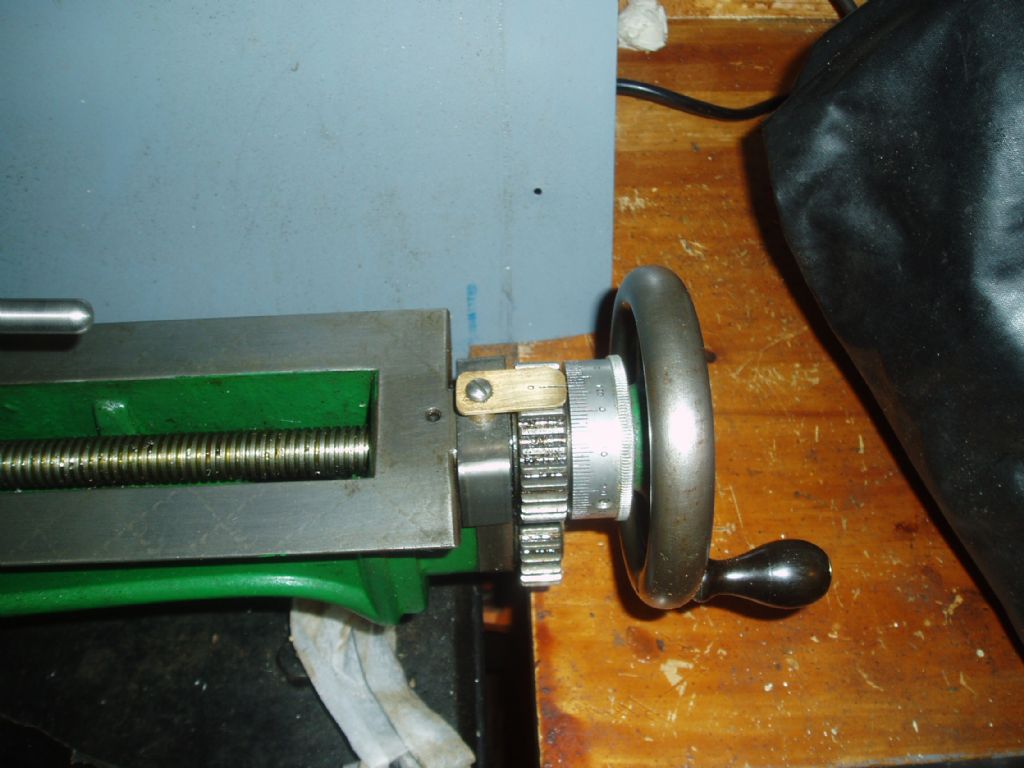

In 1925, Drummond brought out the M type which is really an uprated B with a stiffer headstock, so did away with the loop on the casting. They also added a rack and pinion for moving the cross slide along the bed but be warned…turning the handle clockwise moves the cross slide TOWARDS the headstock!

B and M parts do not fit the Pre A, but many are interchangeable between the B and M as they used the same bed, such as cross slide, topslide, tailstock, and changewheels.

The M tailstock is recogniseable from the screw adjuster at the back for offsetting while the B type is a plain ‘slide and hope’ type

In 1942 the Ministry of War Production told Myford to take over the manufacture of the Drummond M type so that Drummond could concentrate on their larger lathes.

Myford used Drummond-made parts until they ran out, and used the Drummond serial numbering system too…for a while.

By the end of the war, Myford had added a changewheel guard made of cast iron and went on to ‘electrify’ the M with an electric motor mounted on the back of the stand.

Myford brought out their new model 7 in 1946, but carried on supplying Ms until the late 40s/early 50s.

There are NO interchangeable parts between Ms and 7s! The beds and headstocks are completely different, as are changewheels. The T slots on the cross slide are slightly different dimensions and spaced differently too so topslides don’t fit except with a bit of engineering.

For a full account and some brilliant photo essays on the Drummond lathes go to Tony Griffith’s website as I mentioned originally…in fact, everyone should visit as it is the most comprehensive machine tool archive in the world!

Hope your workshops are becoming more habitable after the cold.

Andy

geoff walker 1.