The first thing I'll say is bear in mind that these bits of kit are designed for a wide range of environments, and in some of them the fact that the scale is stuck to the substrate is actually a good thing from a metrology (accuracy) point of view. I could go into more detail, but in our world the benefits gained from having a scale that stretches as the substrate changes shape due to thermal expansion are by far outweighed by the physical environment. So…>>

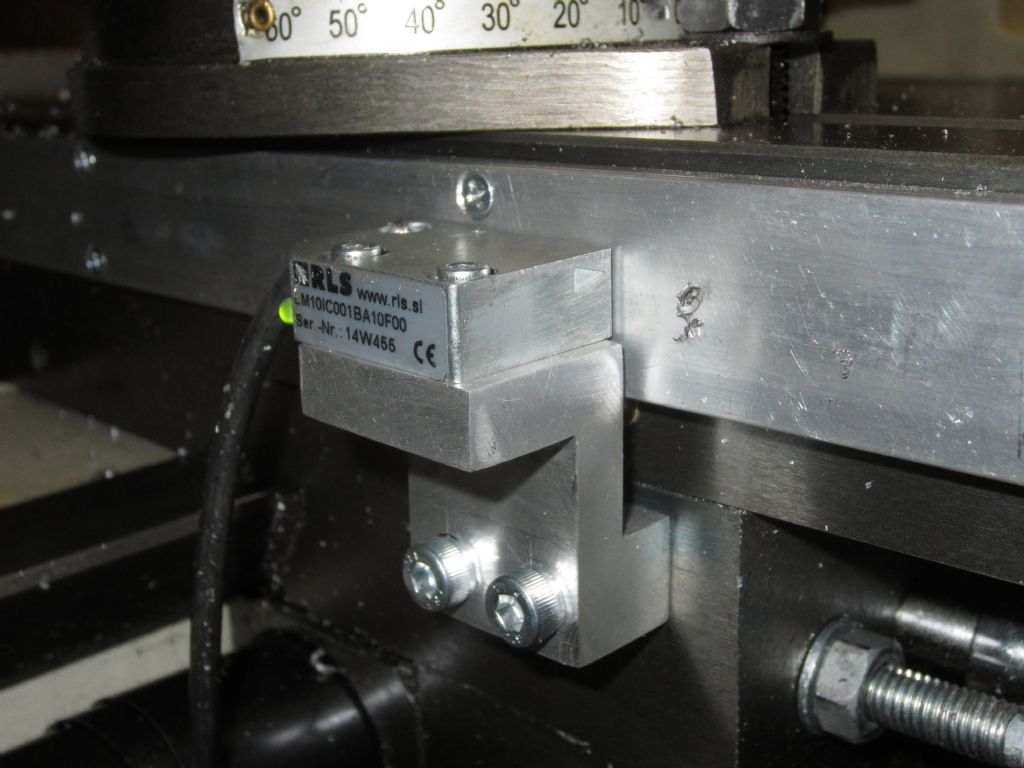

I simply mounted the scale in a 2-part support profile (link in previous post). These consist of a bottom part with mounting holes that you screw to your machine and then stick the scale onto, and a top cover, that screws to the bottom part and completely covers the scale protecting it from swarf and coolant and being bashed. The readhead is perfectly capable of reading through the ally top cover with no affect on accuracy (ok, there is a tiny one, but being in the region on nm we can ignore this error source too!). The photo below shows the bottom part mounted, ready for the scale to be stuck to it and the top cover screwed on.

The scale is magnetic and I guess, could get damaged by introducing foreign magnetic fields. However in practice you'd have to be trying pretty hard, i.e. by mounting a mag-base for a DTI right onto it, and even then you'd probably be ok. To give you some idea, I managed to put some scale in the same plastic carrier bag as a replacement motor for my lathe, and had no probs. The actual fields themselves are fairly small and don't radiate much above the surface of the scale so you'd basically have to place a strong magnet right up on the scale itself to damage it – and remember we've now got a cover on it so we've got an extra layer of protection.

You're right, these are serious pieces of kit, and new they cost several hundreds of pounds. But they can be sourced much more cheaply on eBay and I'd much rather have a product designed precisely for this kind of application than one based on dismantled calipers or otherwise. That said, £300 was for me affordable, and for others it may not justify the cost.>>

Captain Biggles.

that they have a really wide range of setup tolerances.

that they have a really wide range of setup tolerances.