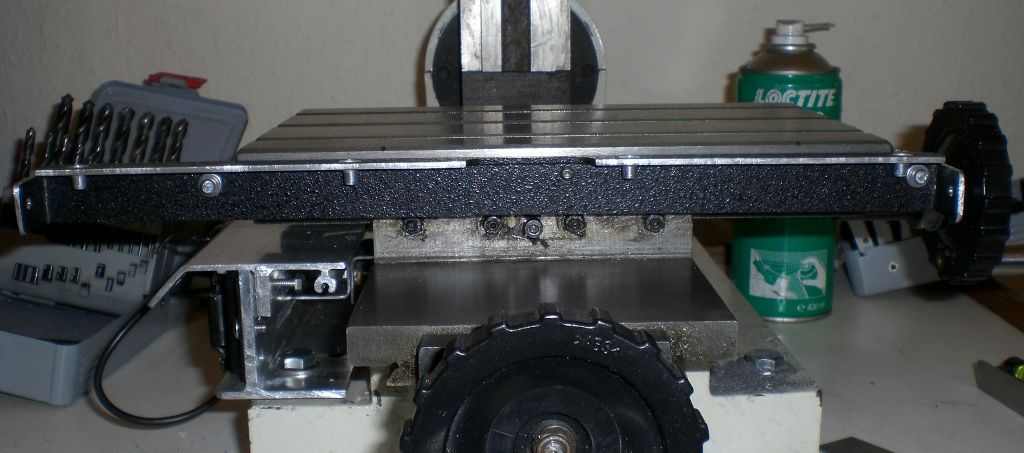

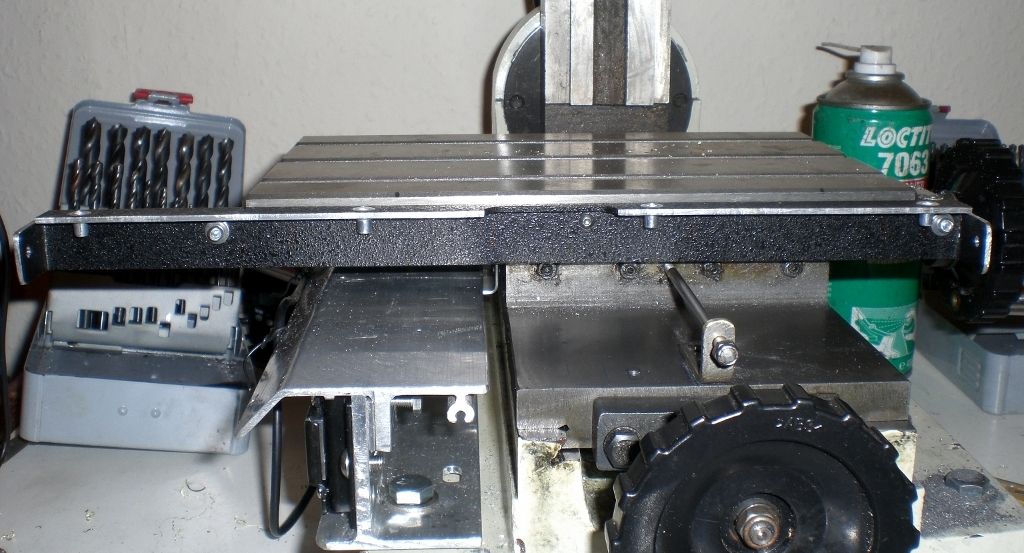

Hi, the aluminium extrusion in the photo below was salvage from a scrap Telex printer and is what I have used to mount my Y slider bar onto.

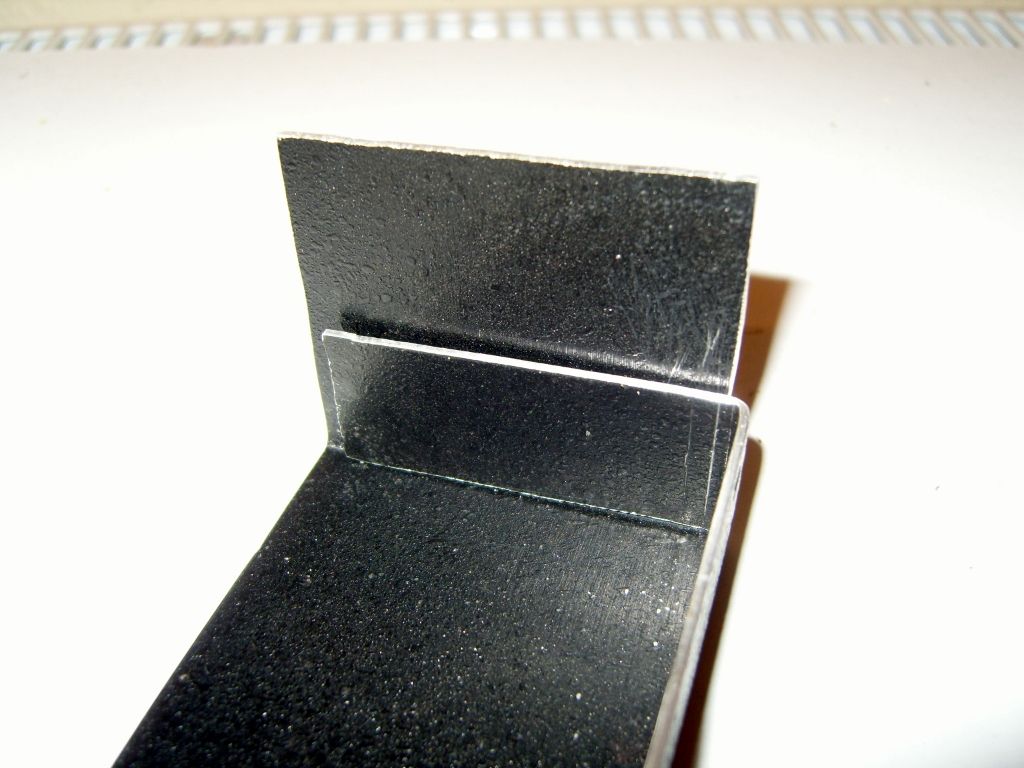

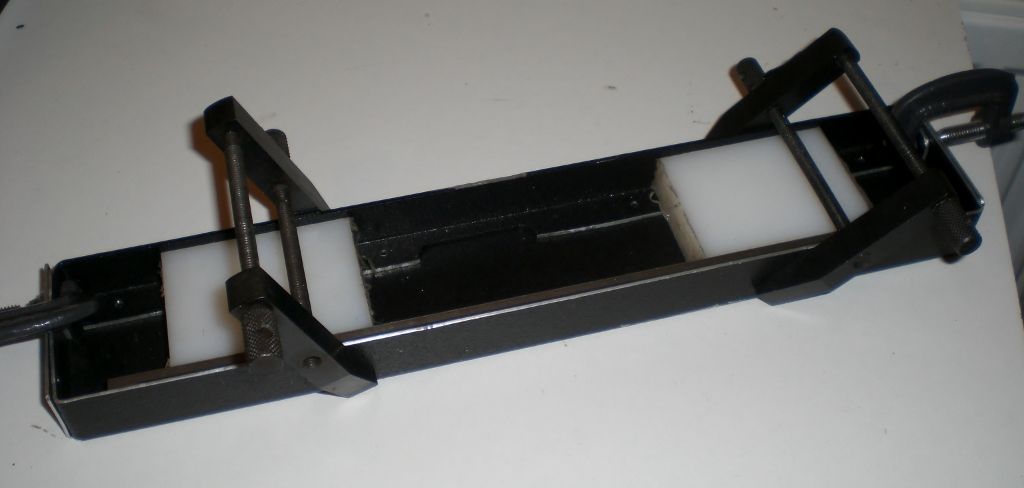

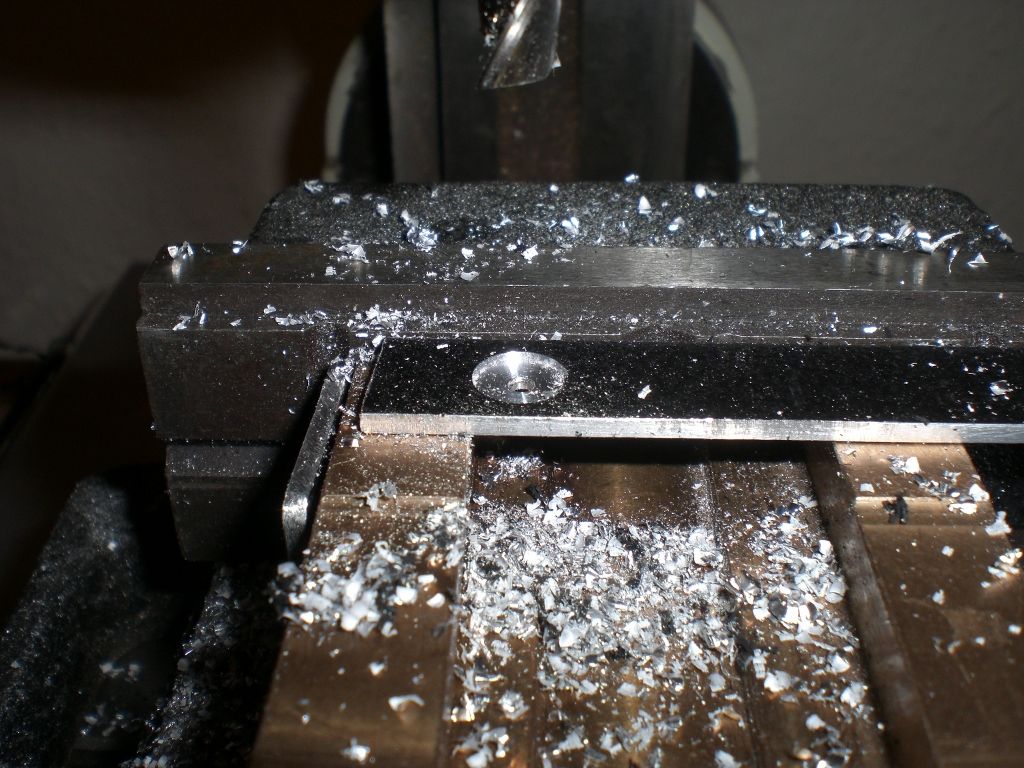

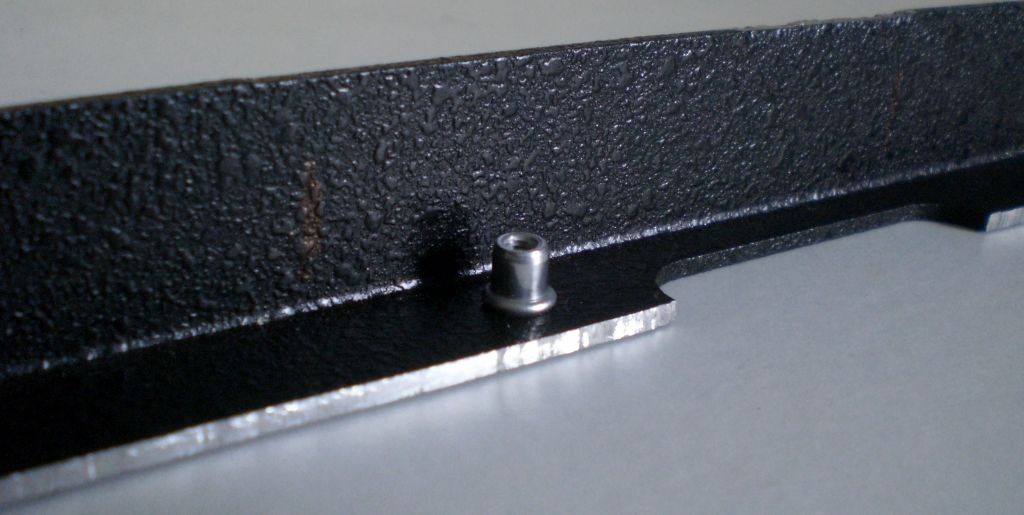

This had to be cut down, as it was too tall to fit under the mill table. Firstly using a hacksaw the upward angled bit on the left hand side was cut off at the bend and then the whole of the top part was cut off 20mm down the vertical web, then the section on the right hand side of the top, with the screw in it was removed as best I could with a normal 125mm cutting disc in my angle grinder. All the cut edges were then trued up on my mill and the two parts were cut to the required length. A 5mm slot was then milled into the lower part of the vertical web of the bottom part, long enough to accommodate the slider bracket for the full length of the slider bar. A hole was drilled in each end of the left hand side of the horizontal part of the bottom piece, to allow it to be bolted down with the bolts that hold down the left hand side of the mill. The vertical web of the top piece was drilled and tapped and matching holes were drilled in the vertical web of the bottom piece and a 15mm X 2mm packing piece was cut and drilled to allow it to be sandwiched between the top and bottom pieces, when they are bolted together.

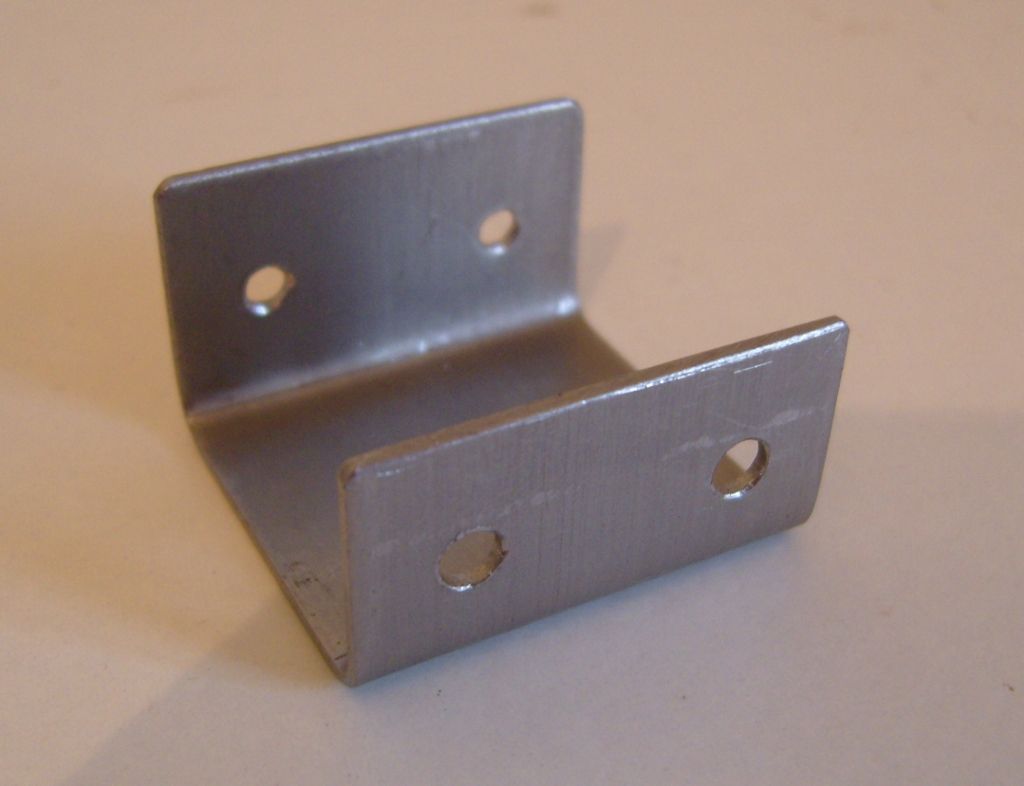

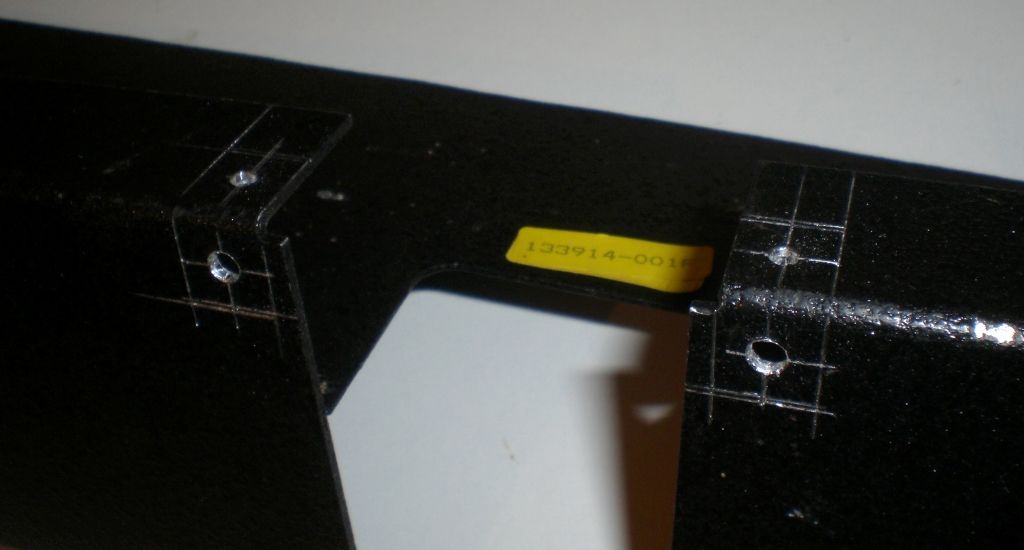

A new bracket was pressed up for the slider, as the one that came with the unit was no good for my purpose.

An extension bracket was also pressed up to attach this bracket to the cross slide of the mill, then the earth pin from a scrap 13A electric plug was soft soldered on, to correspond with the two holes in the slider bracket and were drilled and tapped for the same.

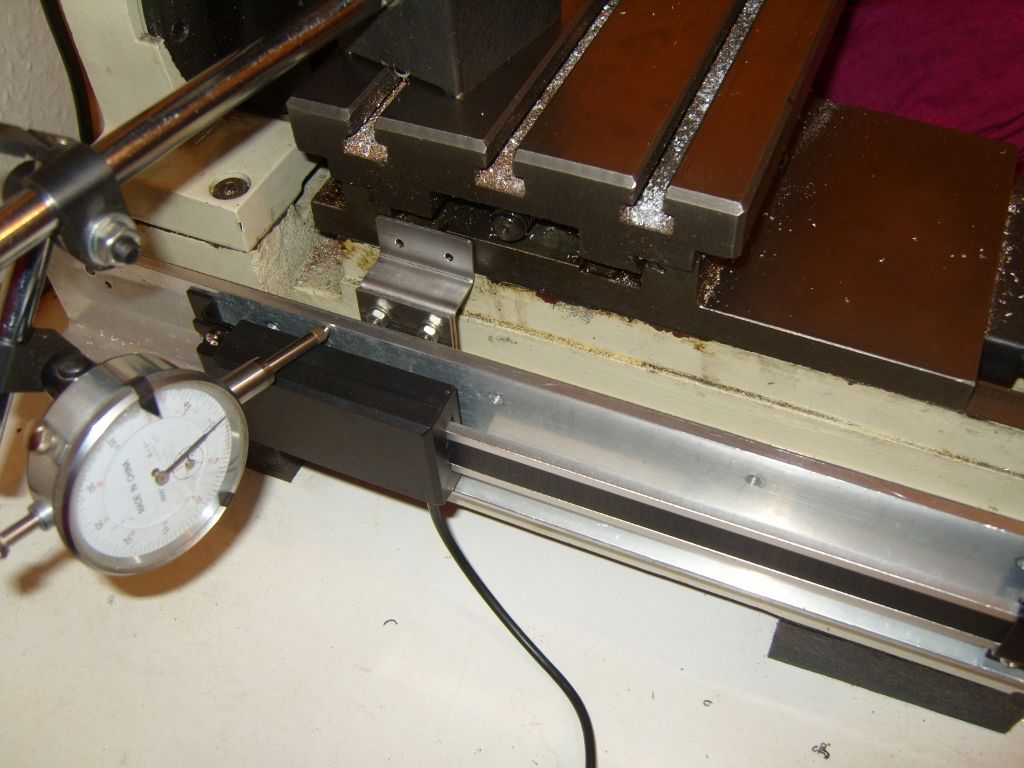

The lower piece of the carrier had the slider bar fitted to it together with the slider bracket and extension piece and was mounted onto the milling machine, Then a DTI was set up to check that it was clamped down parallel to the cross slide, before the two holes were marked through the extension piece onto the cross slide and were drilled and tapped.

Regards Nick.

Edited By Nicholas Farr on 23/11/2015 23:23:36

Nicholas Farr.

Nicholas Farr.