Posted by John MC on 15/04/2023 15:48:42:…

My last thought would be to use a mains USB adaptor connected to a voltage control device, (as in the previous post). Would this be electrically clean enough?

Probably, except for the electrical noise picked up between the wall-wart and the DRO. The DRO expects a few clean DC microamps but what it gets is DC with a strong whiff of mains-hum, high frequency switch-mode spikes, and transients from motor brushes, VFDs, and other electrical clatter. Microamp level noise on the line is usually harmless because it's tiny compared with the hundreds of milliamps normally delivered into the load by the wall-wart, plus the load is decoupled to remove it.

A DRO of this type is unlikely to have any decoupling because there's no long power lead acting as an antenna, and batteries don't add electrical noise.

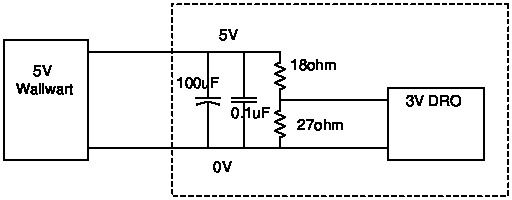

I suggest a circuit that replaces the missing decoupling and reduces the relative level of unwanted noise by loading the wall-wart more heavily. Should also improve it's regulation.

All the components inside the dashed box must be as close to the DRO terminals as possible. The wall-wart cable can be as long as is needed. Works thus:

- The 18 ohm and 27 ohm resistors together draw about 67mA from the wall-wart, giving it something to chew on.

- The resistors help limit any voltage spikes on the line

- The resistors are arranged as a potential divider, making 3V available to the DRO, which taps off the few microamps it needs. As its current requirement is small compared with what the resistors are guzzling, the supply should be 'stiff' – not changing when the DRO is operated.

- A 100uF capacitor is strapped across the line to short low frequency noise like 50Hz mains hum to ground.

- A 0.1uF capacitor is connected in parallel with the 100uF to short high frequency noise like switch-mode spikes to ground. It's needed because big capacitors react too slowly to short out fast changing voltages.

Comment: 100uF and 0.1uF are typical values. I'd expect them to work, but de-noising can be a fiddly job. The optimum depends on whatever noise is actually present, so it may be necessary to experiment, or do the maths necessary to design a proper filter.

Keeping it simple, if the DRO misbehaves, start by adding a 0.01uF capacitor directly across the battery terminals. If that doesn't tame the beast, try various substitutes for the 0.1uF between, say, 0.47uF and 0.047uF. Easier to do with an oscilloscope, but not every workshop has one!

Dave

Edited By SillyOldDuffer on 16/04/2023 09:16:38

not done it yet.