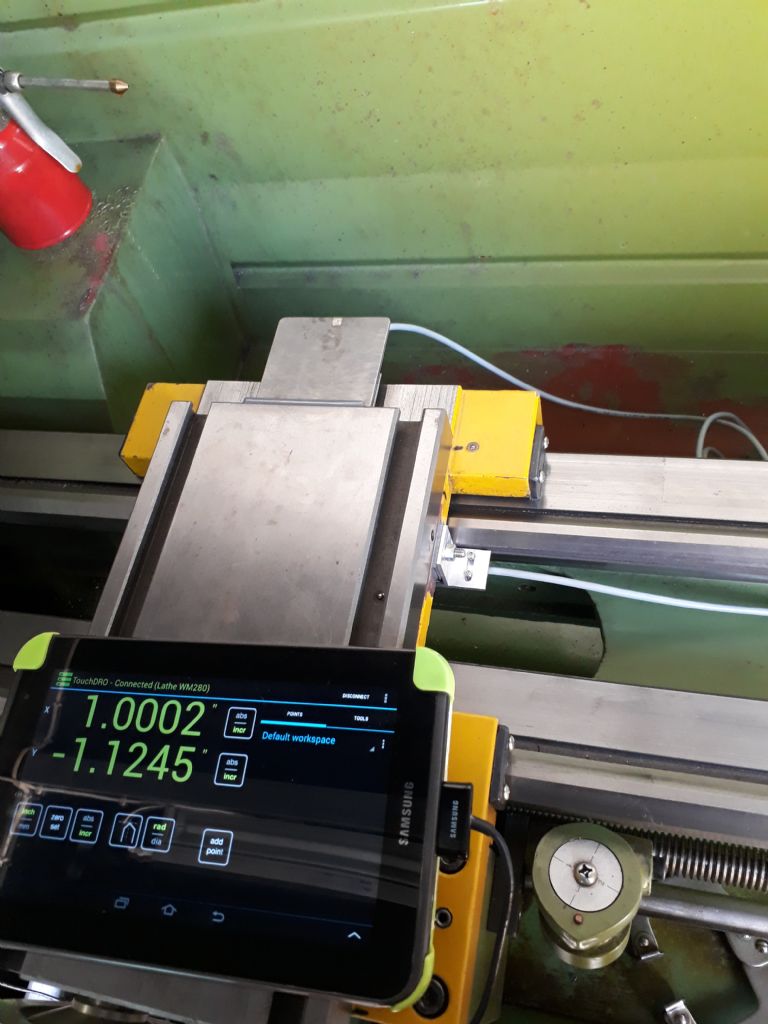

DRO seems to be getting cheaper these days (at entry level).

I am wondering about dro installation on my mini mill, in particular. There seems to be more room for mounting the scales than on my min lathe; I have enough trouble fitting things in and drilling small parts on the lathe, without interfering with the cross slide further.

Many of the cheaper systems warn that they are not water / fluid proof. I can imagine that could be a problem. (???) Also, I rather fancy a magnetic scale which could be cut to fit exactly. It's not always obvious which is which on the eBay ones.

I have a converted tyre tread depth gauge which fits (magnetic) on various parts of my lathe and gives useful ad-hoc measurements BUT it has a habit of suddenly going loopy and the display shows random numbers until the motor is turned of and on again. I could buy another one, of course, if it would solve that (interference?) problem – has anyone else tried making one? They're great value at about £8, iirc plus a couple of magnets. I have also seen digital callipers converted for the same purpose.

andrew lyner.