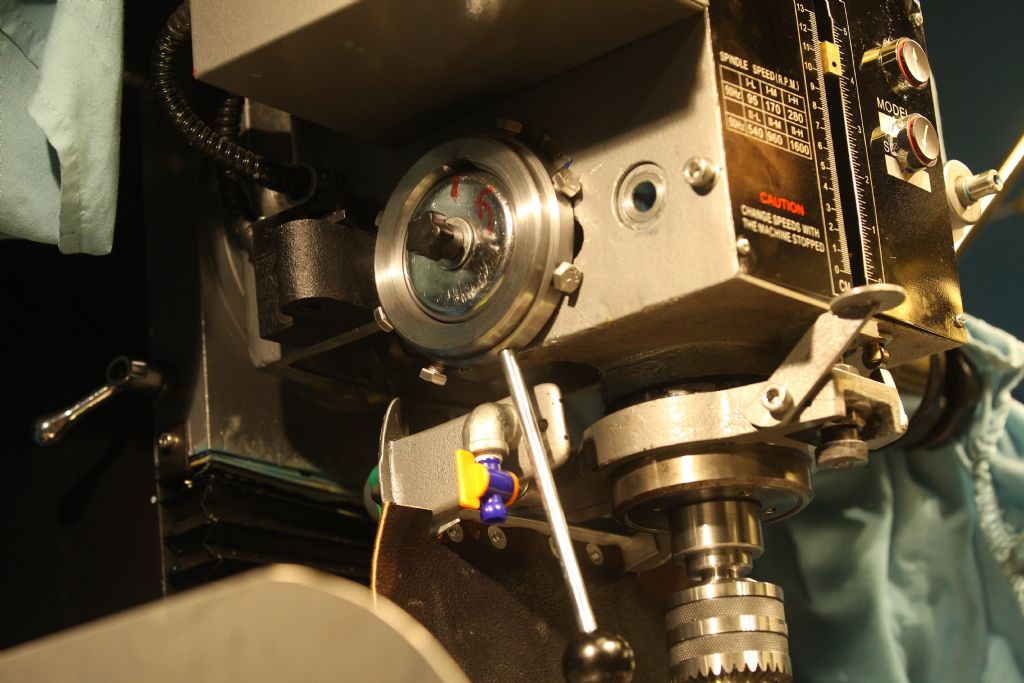

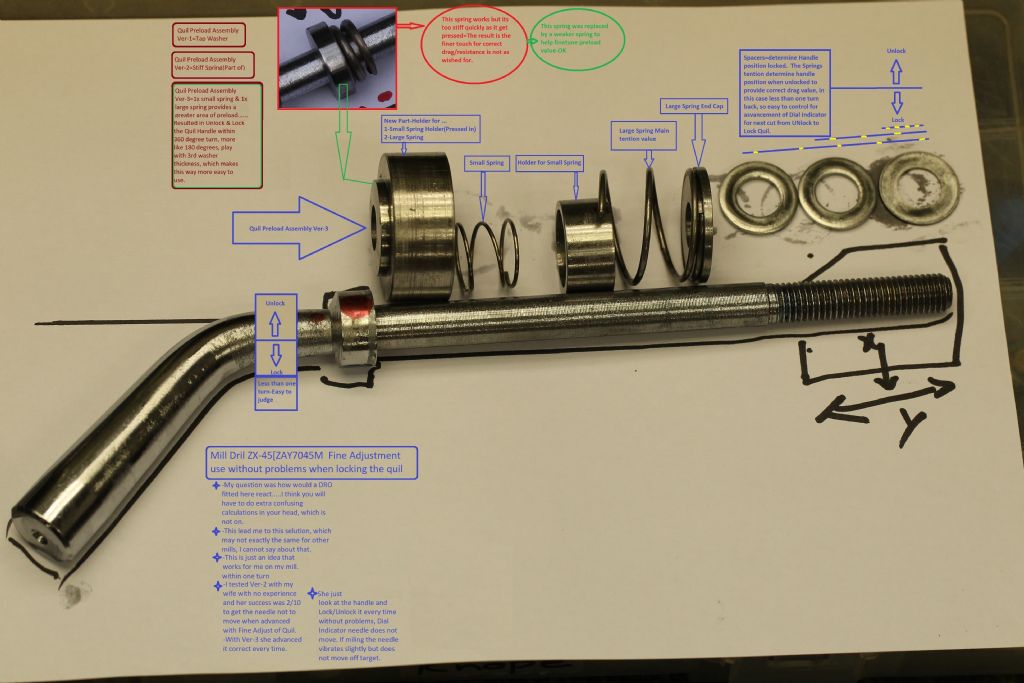

YC Lui, I understand what you saying, my problem is how the guage I am using to go down step by step as I mill.

Due to the problem you mention, I could not trust my guage, and my question was how accurate due to this would a DRO be…. I prefer the guage(Dial Indictor) knowing this now, because its very easy to observe a needle swinging rather han a DRO given numbers that jumps up or down and I have keep on computing that in my head.

Even without the selution the dial indicator will be an uneccassary effort to keep track at wich dept you were and where you aiming for.

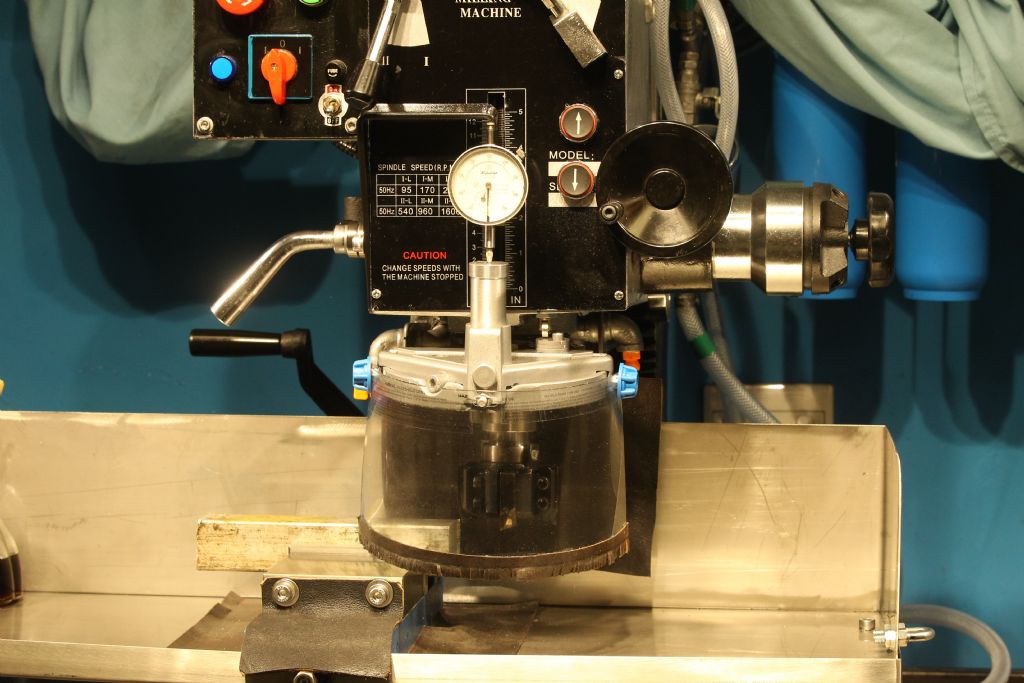

Now with the selution what I see on the dial indicator after locking the quil is the same as before locking the quil is the same as which nect depth of cut I adjusted it to, so I go forward straight forward.

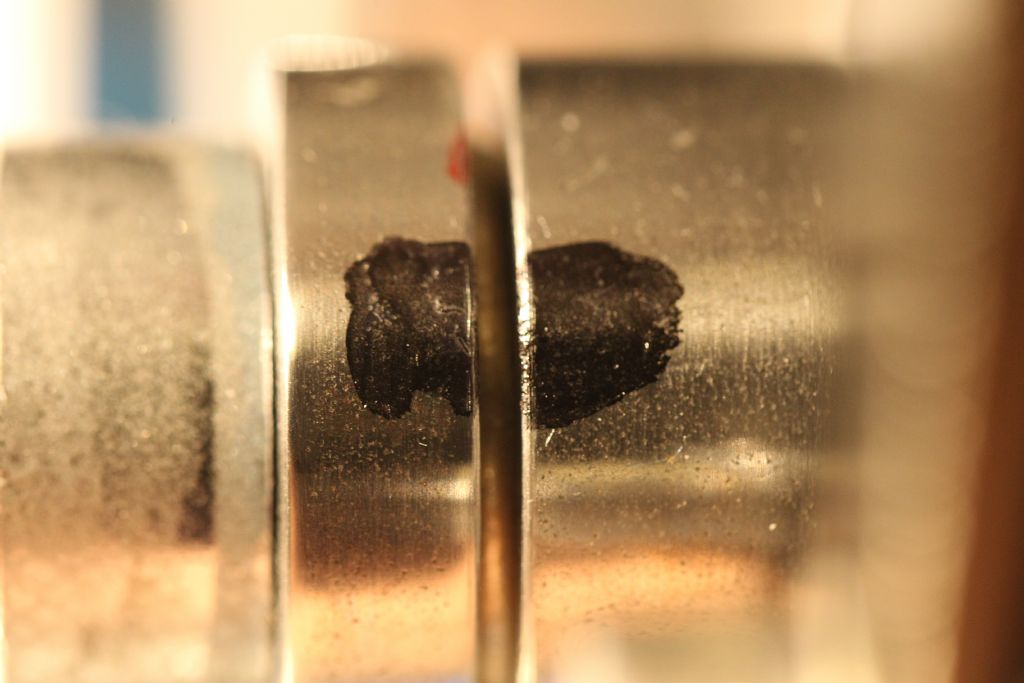

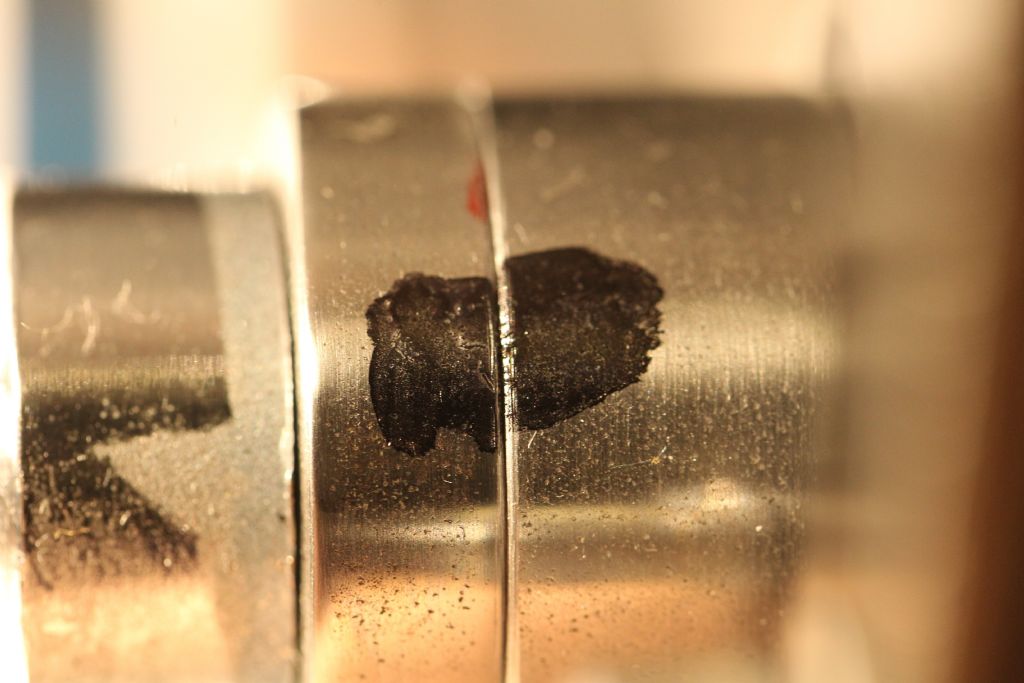

Think about it like this:Before the selution, if you advance the quil down say0.01mm then the dial indicator does indicate that, now you lock the quil your indicator jumos 0.05mm. Because of this it mess with your head as you going forward.

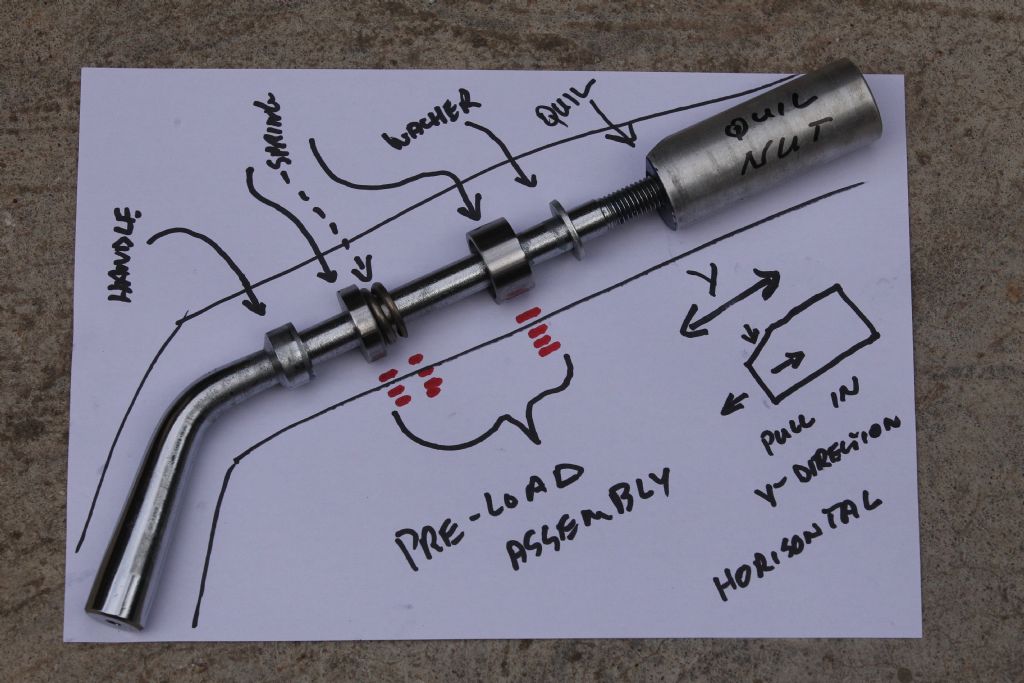

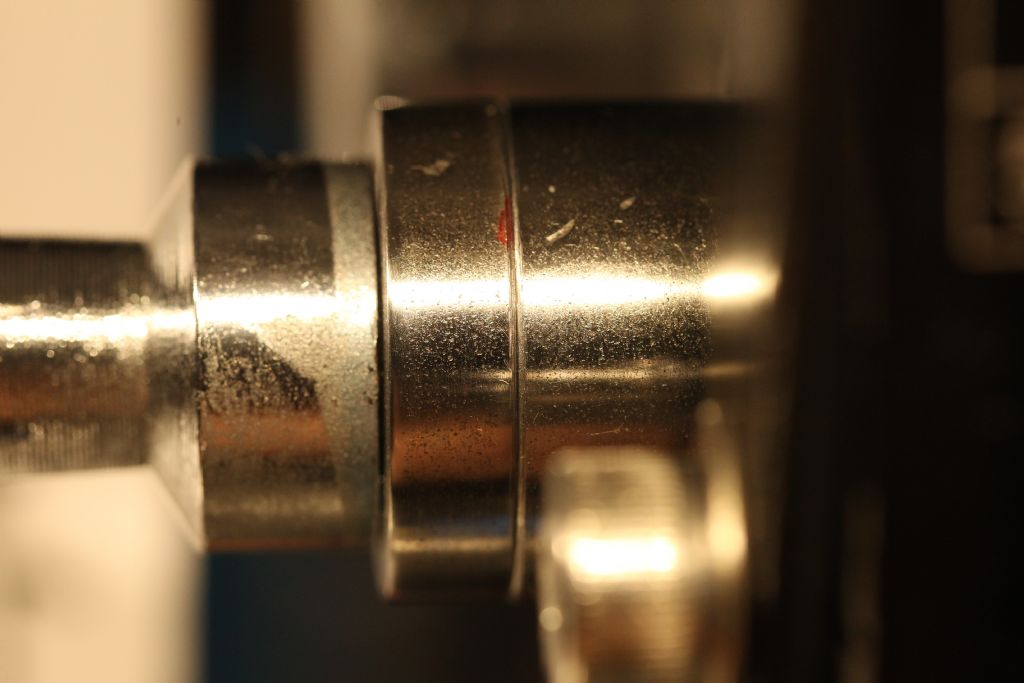

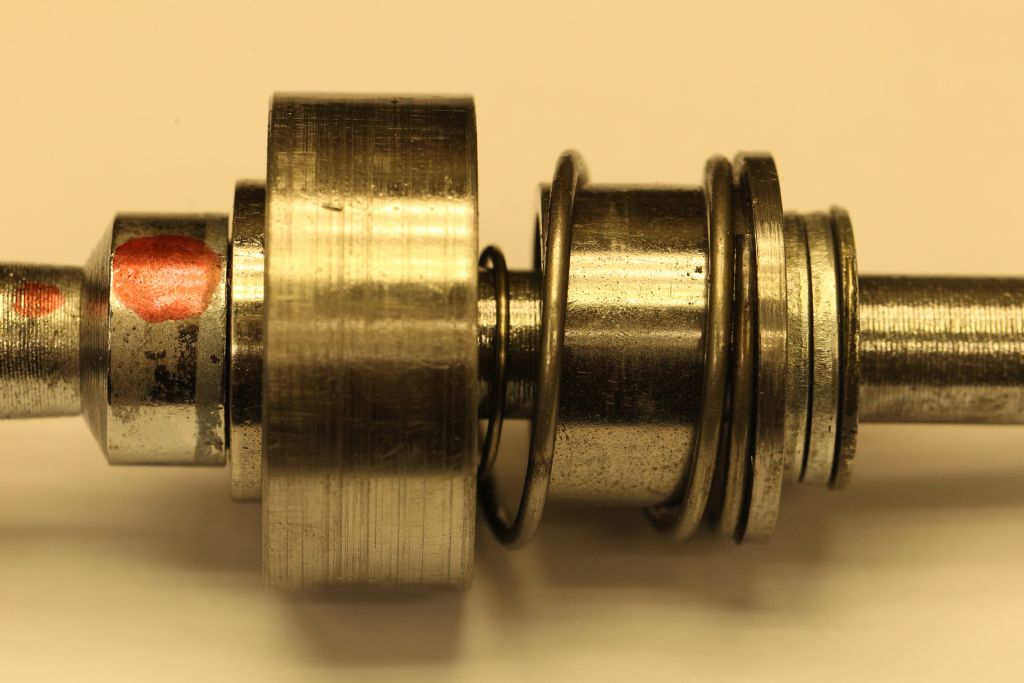

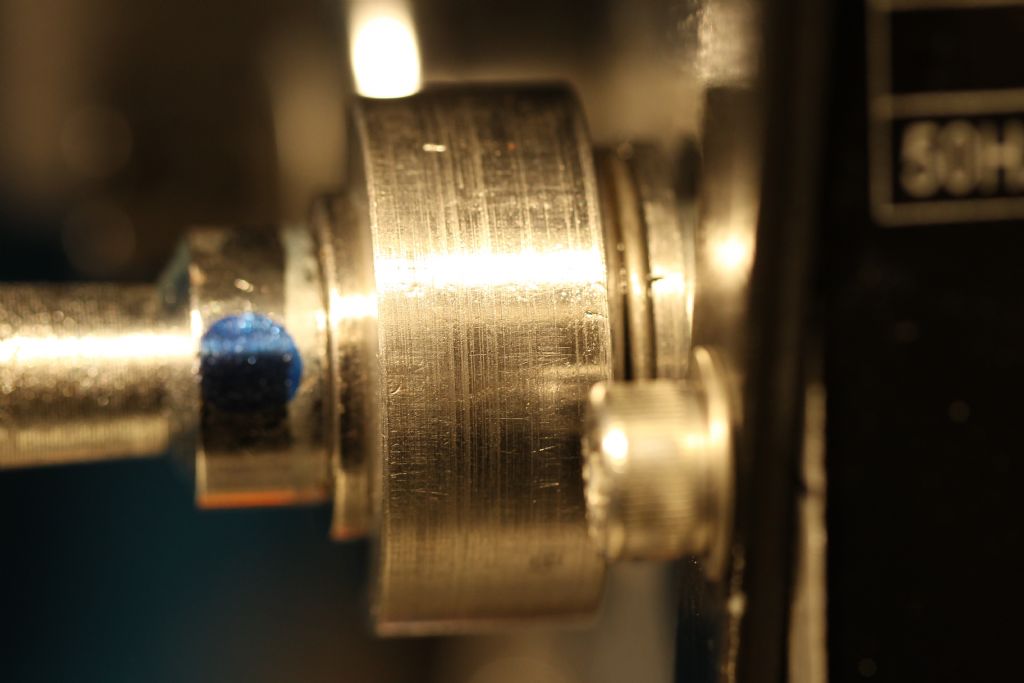

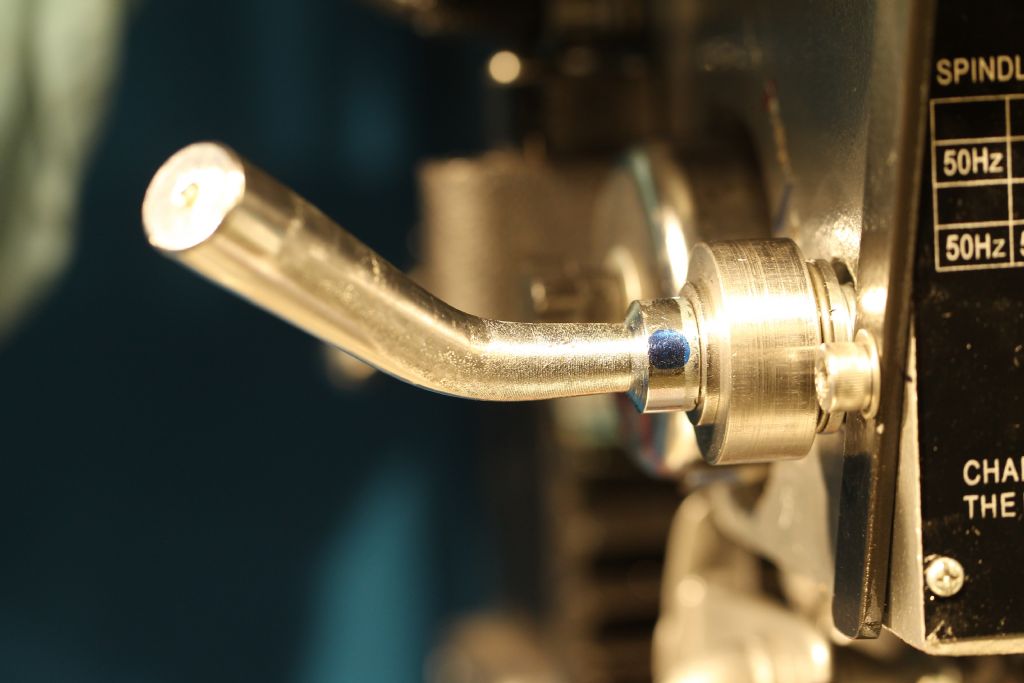

I know have a selution that workd for me with the tap washer, I am going to try to improve on thsat by maching two round pieces with a spring in the one to compress for preload, like the washer. The spring will be longer laster.

Note: The ideal in this Quil-Spindle-Fine adjust engineering would have been such that wherever you lock the quil down that is the position it sit before the pockdown, so it does not move. I can probably make a contraption doing this, but not at this stage with what I got. I have to plow in more money for cutters and MT Collet holders and collets, just face milling at the moment to sort out some problems I can eliminate.

Note:If you mishandle the preload(too stiff), or lock the quil, then touch and turn the fine adjust, you are presented with a complete new problem if the quil is unlock…Now it jumps to who kmows where, so once you started milling down in steps, you must not loose track of the backlash in the fine adjust wormwheel.

Play with tis and you see what I mean…Now with the selution you can take it back to where you came from by using the preload.

Note:I did look at my mill heastock adjustment with crank handle and will fit a DRO to the vertical ways, this will be no problem. Actually it does go down easily and smoothly and thats the direction I am milling in any case, its just as it is more cumbersome to use as the fine adjustment, unless I modify it, using a 90 degree small gearbocx and with steering universal joints bring it forward beneath the left side of the bed with a proper handwheel to adjust.(I will probably do this).

Y C Lui.

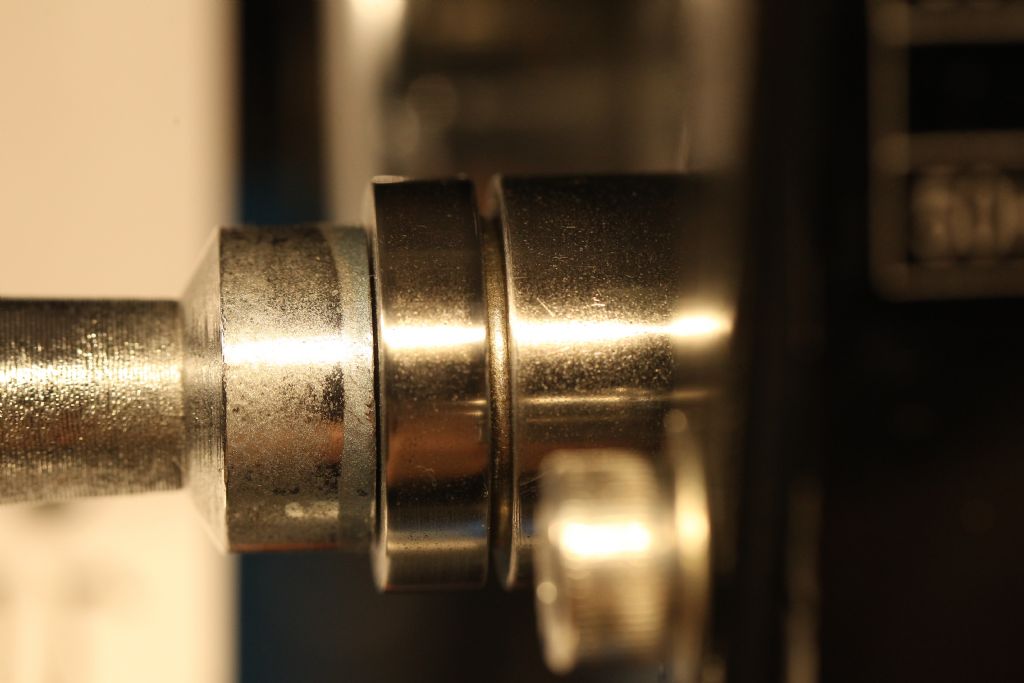

, you will have/can have zero deflection if you lock it-? I am trying to seperate an engineering issue due to desighn from faults.

, you will have/can have zero deflection if you lock it-? I am trying to seperate an engineering issue due to desighn from faults.