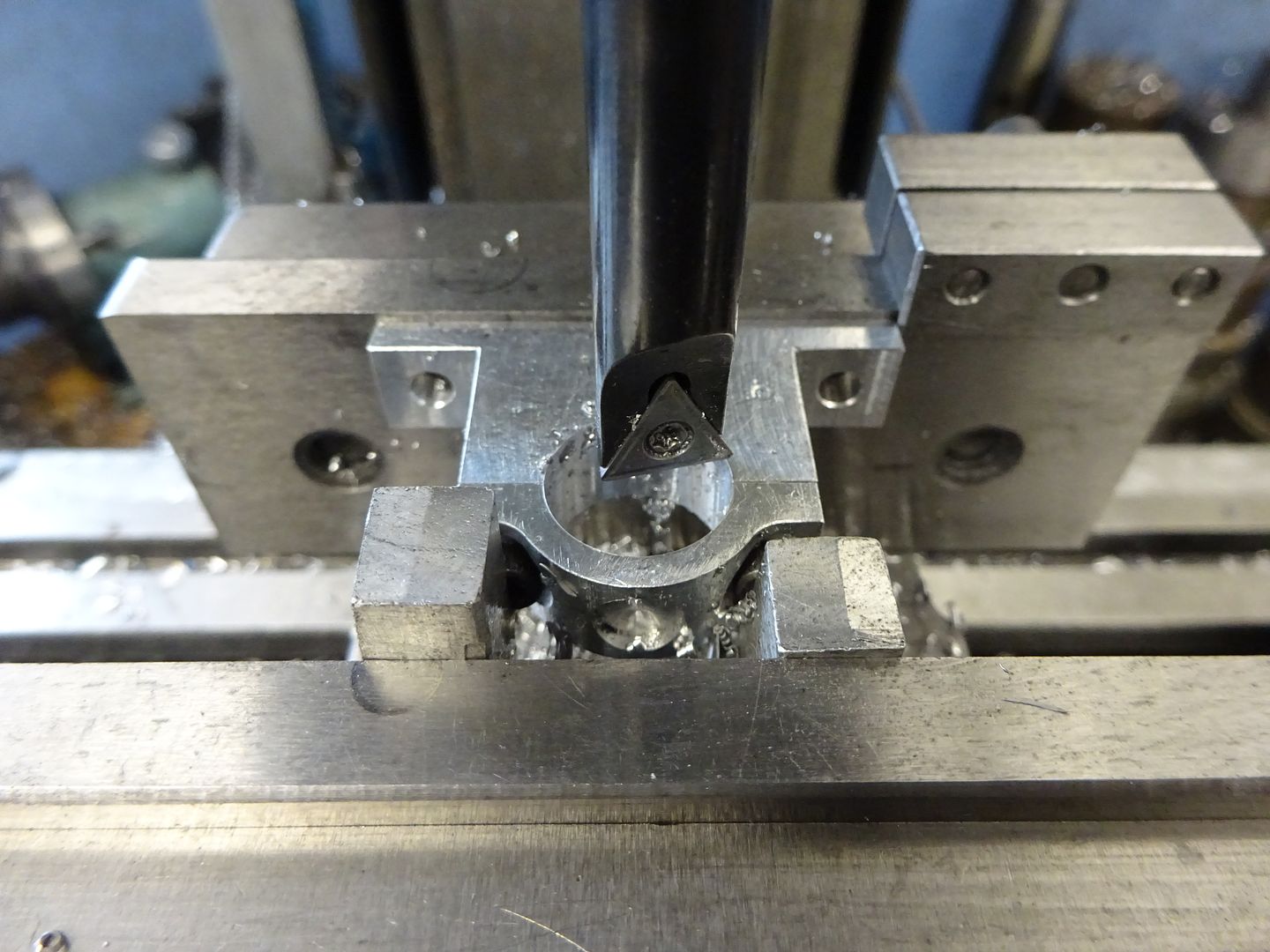

With regards to the holes in the feet if while you have the casting upside down to flatten the bottom you also take a light cleaning up cut off either end you then then have two points of reference and can locate their centre and set everything else out from that. If you look at that image I posted I'm using one end of the "foot" against a stop so that I only have to find the ctr once and then just swap the two pedestals over.

The same stop can be used for the second ops on my list and the boring of the bearing so everything is located equally either side of ctr.

I have not read Stan's build but at the time he was writing many would not have had a mill in the workshop let alone one with a DRO so some of his methods are a bit dated now.

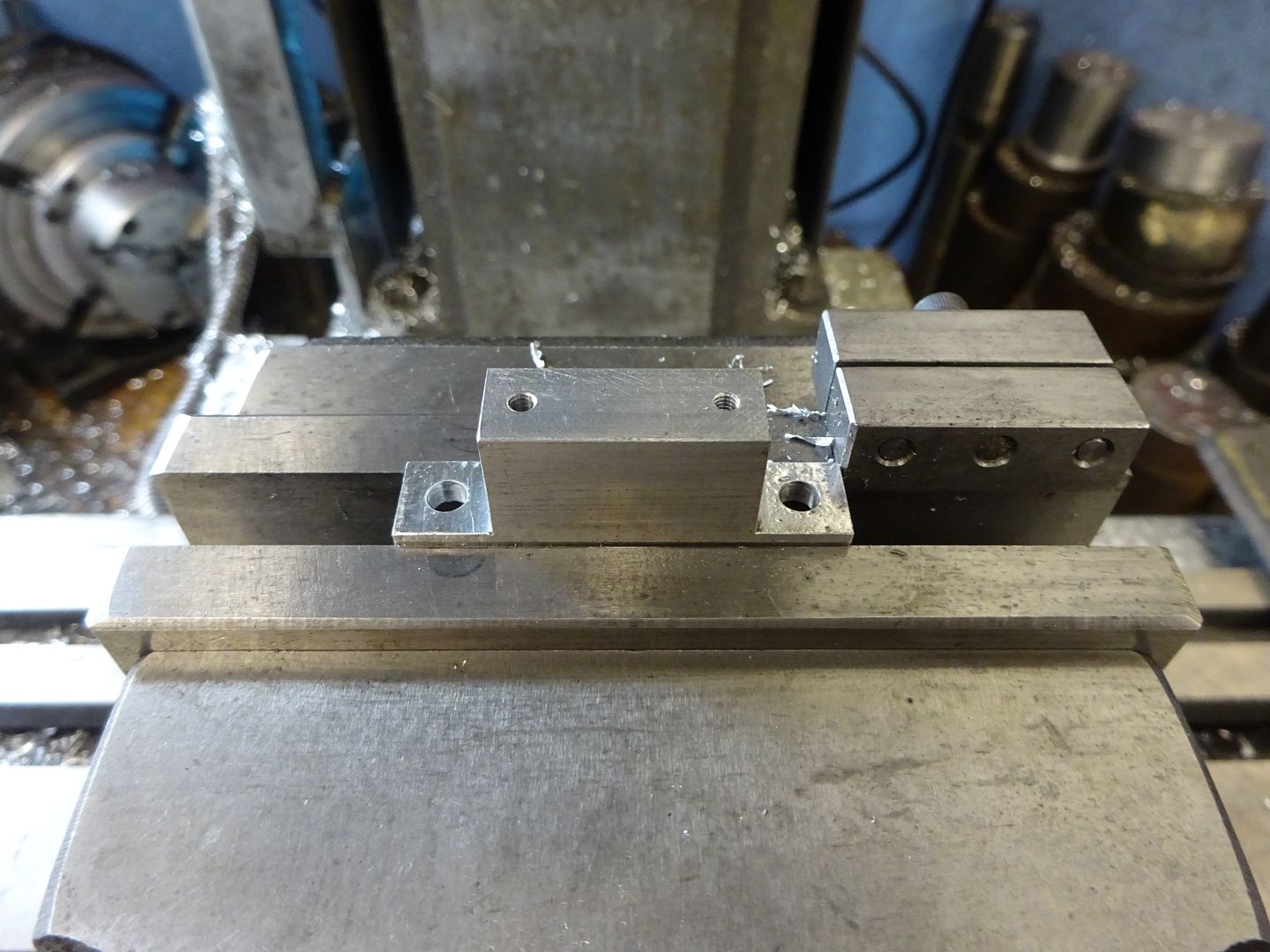

These days I would clamp the bed casting down to the mill table, clock it true and establish my datum. Then mill the various bosses flat before drilling the holes for cylinder, cross head guides and bearing mountings all in one setting using the DRO to position them. Its going to be more accurate than marking out, picking up punch marks and spotting through from other items. I would then expect each item to screw on with little chance of not lining up.

Edited By JasonB on 28/01/2022 13:20:42

anderalex.