I have a basic rule of thumb where the larger the angle the easier it is to drill by hand

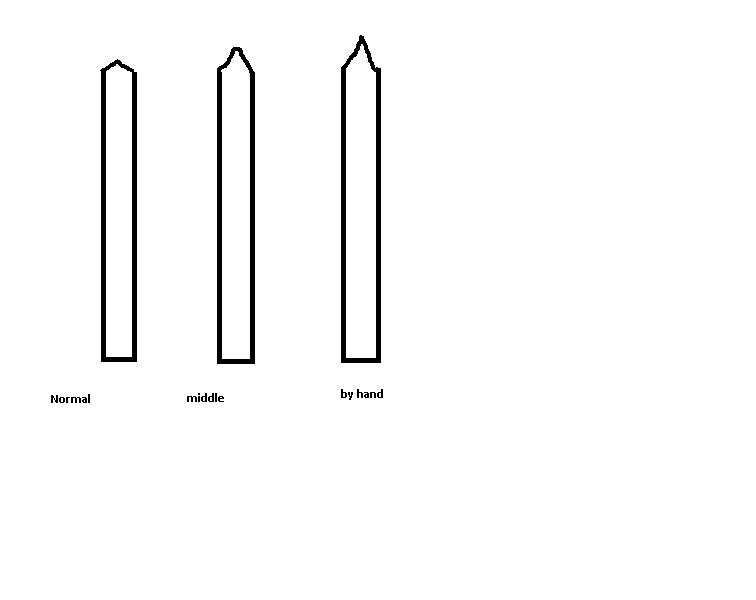

Here is a totally unscientific drawing

The more pointy it is the easier it is for hand drilling in steel and the more it grabs the work if you push hard with a machine tool so you use it lightly in any machine

The cutting angle is between the part you grind and the inner spiral

If you can hand grind for hand drilling steel then machines are easy peasy

When you hand drill steel always always use a pilot drill of about 3-5mm max to clear the centre area out

Hand drill steel at low speed to save on drill wear, 2-300 rpm, once you get some skill and experience you can up the speed as required

A well ground drill is your pal and cuts into the metal straight away, no metal means a regrind

Grinding for a machine drill is about grinding a less acute angle because even cheap machines can apply such huge pressure at the cutting edge compared to a puny human and the drill should also last longer with more meat at the cutting edge

Edited By Ady1 on 08/07/2021 16:59:02

bernard towers.