MichealG

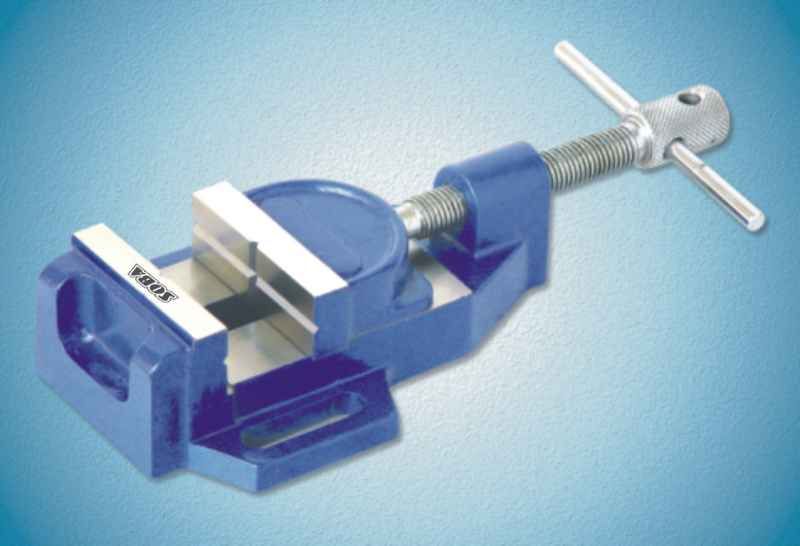

Unless there are serious constructional or manufacturing deficiencies there is, from the specification at least, nothing wrong with that little Eclipse vice.

For the job it is designed to do.

Namely hold parts or stock by gripping along the line of the jaws so they may safely be drilled. Some degree of float in the moving jaw is a desirable trait as drill vices must be made to accommodate completed parts, unfinished stock and similar items that may not have both sides true.

Complaining that it won't do other things is silly. At the inexpensive end of things you have to accept that things tend to be one trick ponies. Although well chosen accessories can often add other tricks to the repertoire.

As I said previously best answer for holding round stock is set of auxiliary jaw pads with a vertical and a horizontal V slots running through the middle. I'd make two one with narrow slots for very small work and one with larger ones. Unfortunately copying the excellent Nippy set up is a non starter as the moving jaw isn't sufficiently stable to cope with the V slots each side of the middle. Actually not a bad idea to make three sets copying the sizes used on the Nippy.

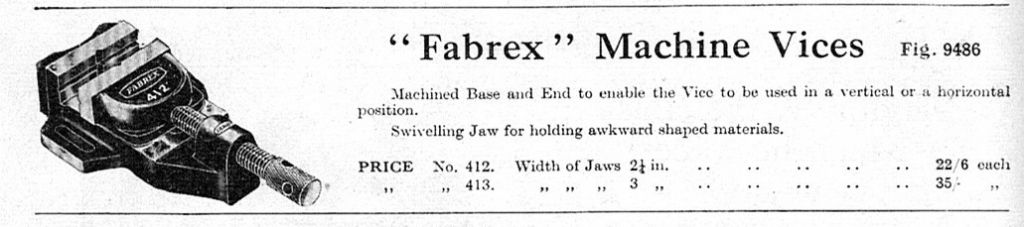

]The Nippy is an excellent vice. I bought one after using one at work.

But the limited float on the moving jaw restricts grip on non parallel parts. I've seen part self ejection when used by careless folk at work

Back on topic I'm a little surprised that no V slot auxiliary jaws are sold for these inexpensive vices.

Better to spend time making accessories for what you have rather than waste money on another cheapie of slightly different specification that will perform no better in practice.

Clive

JasonB.

JasonB.