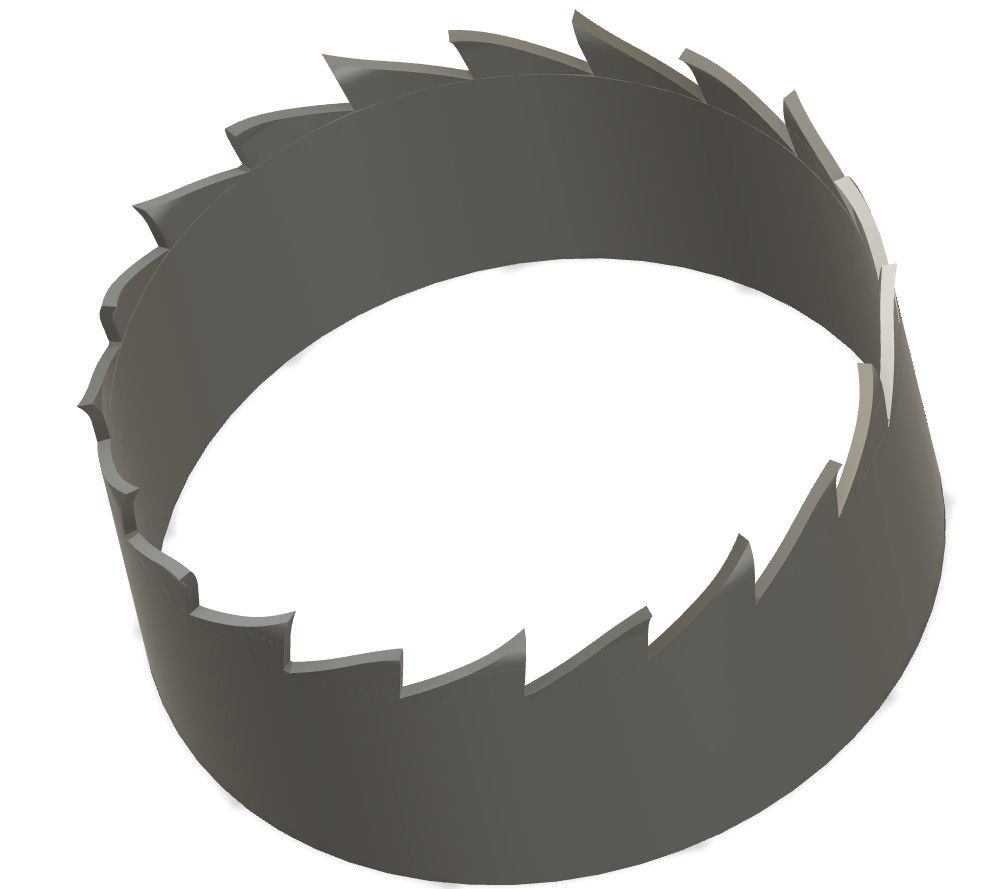

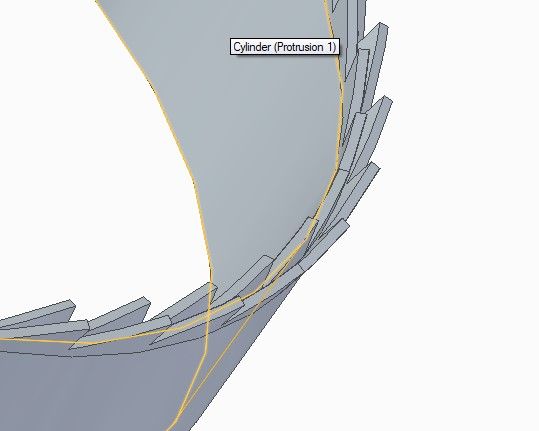

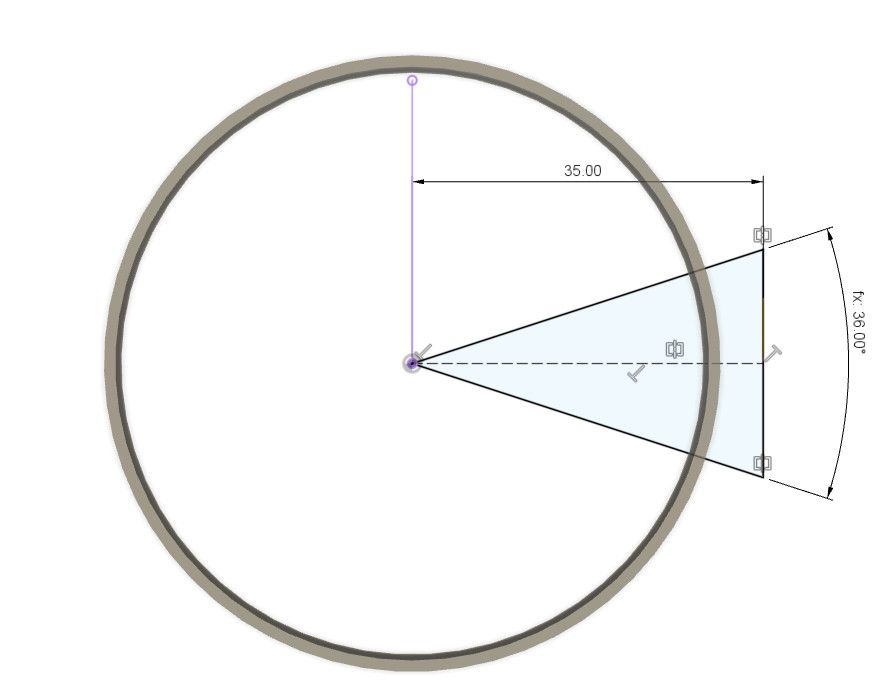

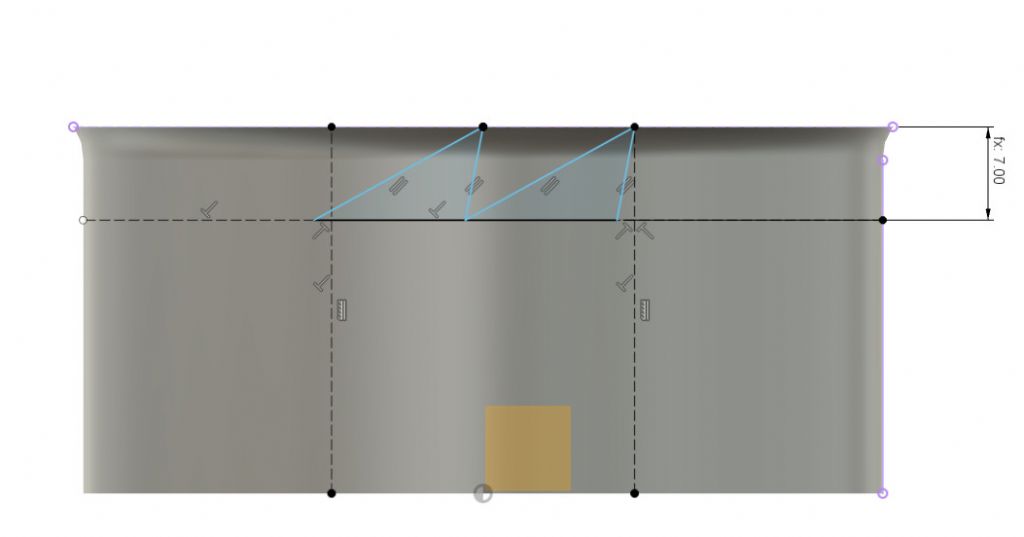

Drawing a saw blade – help!

Drawing a saw blade – help!

- This topic has 28 replies, 13 voices, and was last updated 4 December 2022 at 21:21 by

Model Enginerd.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Mistry dividing attachment

- Hopeless…Alibre Ass

- Lidl castors

- Epoxy or acid etch primer

- Diving in to ATC?

- What Did You Do Today 2025

- Measuring a double Vee lathe bed Vee position

- Please direct me to where I can find an engineer to do some bespoke work

- Making Unimat DB/SL Steadies

- Bad design, or am I missing something?