Posted by Howard Lewis on 25/11/2022 08:19:51:

Might be a left over from a Mutual Improvement Class on BR or one of the preceding Railway Companies.

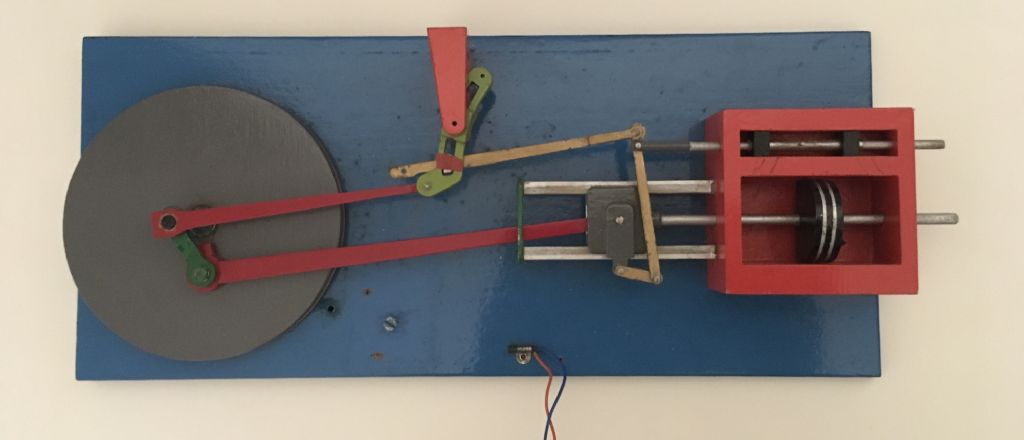

A very useful aid to understanding the operation of the valve gear.

(I can grasp Stephenson';s and Hackworth, but some of the others defeat me. Can never see the difference between Baker, or Heusinger and Walschaerts )

Howard

Or any of a multitude of Technical Schools, Technical Colleges, and Apprentice Training Schemes. Before dieselisation, steam locomotives were a major source of employment making it useful for many people to understand at least roughly how they worked.

Wot I know about valve gear comes from helping Duncan Webster refine and port his valve simulation software. (Duncan did the clever maths etc, my part was refining the software, helping with the GUI, and porting the beast to various platforms. )

The goal of a valve linkage is for movement of the piston to result in perfect timing of the valves, whilst allowing cut-off and lead to be adjusted by the driver, in both forward and reverse. Duncan's simulator makes it possible to compare the various valve mechanisms. The simulator identifies how good or bad the valve events are. Valve performance isn't obvious from just eyeballing the motion, it's necessary to analyse how and when the various levers interact throughout each cycle. It can be done by measuring the real thing, or – more conveniently – by having a computer do the maths. Lots of maths!

Various motions have been designed in the past to achieve perfection, but it turns out there are a bunch of trade-offs between efficiency, reliability, complexity, and ease of maintenance. For example:

- Stephenson produces near perfect results and is reliable, but the gear is slung between the frames under the engine. Great until it goes wrong, when it becomes horribly expensive to maintain. Faults take the engine off the road for ages and the lost revenue costs the company a fortune.

- Walschaerts events are nearly as good as Stephenson, but the motion is more complicated and liable to go wrong. However, it has the huge advantage of being hung on the outside of the loco, making it much easier and faster to fix. Walschaerts' became by far the most popular system for mainline rail because it achieves good fuel economy without spending too much time being repaired.

- Other systems produce inferior valve events and waste fuel, but compensate by being simple, robust, and easy to fix. They tend to appear on working engines where fuel economy isn't the top priority. Baker gear, which is easier to maintain than Walschaerts because it has fewer pin joints, was popular in the US until the cost of coal started to hurt! Then new engines were built with Walschaerts gear.

In the end steam locomotives couldn't compete with diesel, and the need to understand them dropped out of mainstream education. As a result lucky Michael picks up a nice model at a car boot for £2! I've never seen anything like that.

Dave

John Olsen.