Latest update: Lathe DRO installation.

Installed the read heads on the lathe X and Z axes between yesterday and today. The idea was to install the X axis read head and magnetic tape inside the carriage cross slide. While it was possible, it was a bit difficult to do given the limited space and the leadscrew. But following Jason's idea I managed to fit it somehow.

Here's how I went about it:

As I did not want to drill any holes in the carriage I glued a plate with an m5 stud to which I would mount the read head bracket. Here I had to take measurements carefully to make sure the leadscrew nut on the crosslide would not hit the head when it's at the end of it's travel. Also to be noted, that the crosslide cannot be removed by sliding it rear wards for the above mentioned reason.

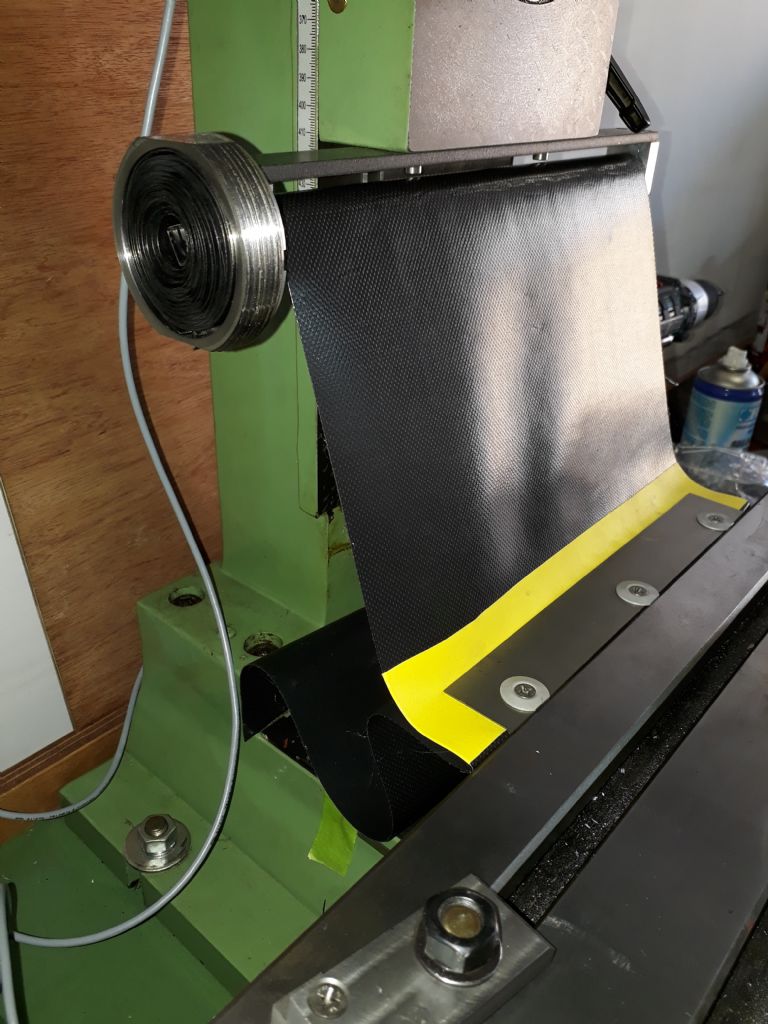

Here's how the X axis read head is attached to the carriage. It's a tight squeeze and a bit fiddly to get to the read head screws (M2.5 allen cap head), but not impossible. I glued a plate to the crosslide which has a dual purpose – the primary purpose is to attach the magnetic tape to the under side, the secondary purpose is to cover and protect the read head and tape from swarf, dust, oil etc. ( in the photo the crosslide is over extended just to show the setup – in normal operation the slide will cover the head.

This is the magnetic tape on the bottom face of the crosslide. Worth noting that the magnetic strip is about 2mm thick, this means that I have to be careful when dismantling the crosslide. There is not enough clearance for the strip to slide between the carriage and the crosslide, so if I attempt to slide the crosslide off I'll damage the strip. The correct way to take the crosslide off is by first sliding and removing the gib strip, and then LIFT off the crosslide.

Next it was the turn for the Z axis installation. I attached the read head to it's bracket loosely. Then the bracket to the carriage was glued, keeping every thing clamped and aligned and left overnight for the adhesive to set.

This is after the adhesive set, next was to install the magnetic tape.

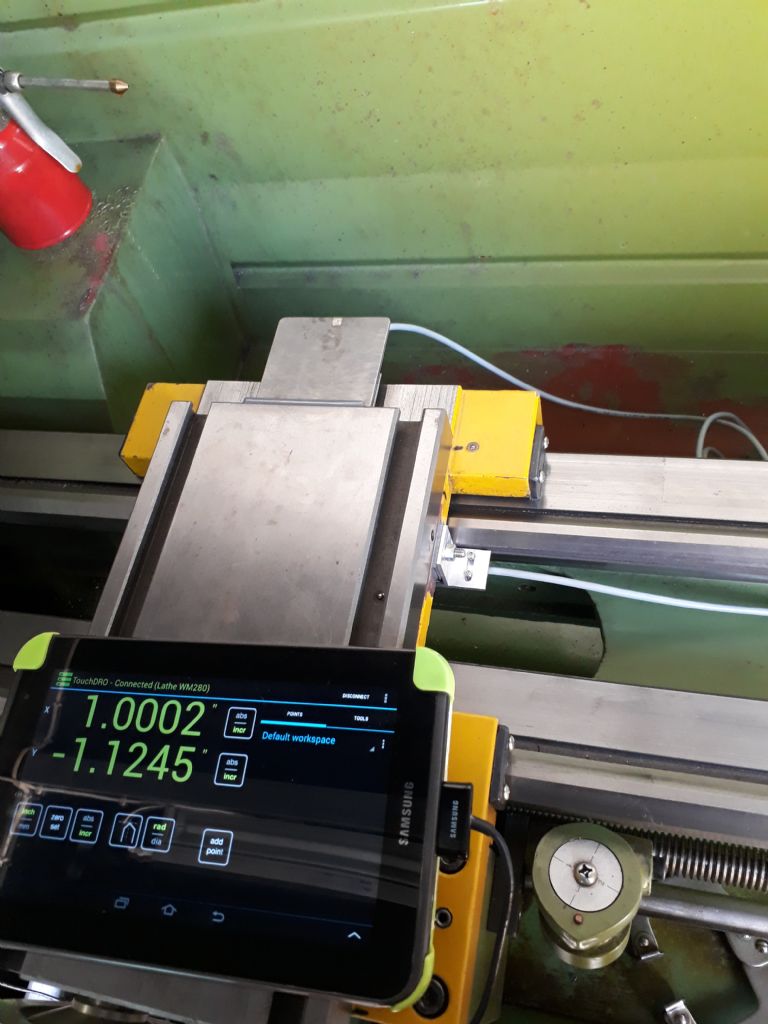

Everything now in place, time to check every thing works and calibrate the readouts.

All that remains is tidying up the cables and build a couple of cases for the touchdro circuit boards as they are still just a circuit hanging on cables!

In conclusion, I would say there was a fair amount of work to make a DIY set of DRO's for the lathe and mill, and if you're in a hurry it would definitely make better sense buying them new. But, for half the price or less, if you have time, it's worth a try to build your own – no special skills required, just patience – a lot of it!

Edited By ChrisB on 03/08/2019 14:09:49

ChrisB.