Posted by Michael Gilligan on 15/08/2021 17:10:17:

Posted by Pete Rimmer on 15/08/2021 15:24:47:

I don't see it as a circular dividing problem at all […]

.

I think that’s pretty-much where we came in, Pete

MichaelG.

I've just tried drawing it and confirm the small pins aren't spaced by equal angles. On my metric version, the angle between the top two pins in a quarter is 1.01069° stretching out to 1.63147° apart at the bottom. So as Pete says, not a dividing problem. The same applies to the adjusting pins, which are offset as Michael said, and staggered on opposite sides to allow space for the screwdriver.

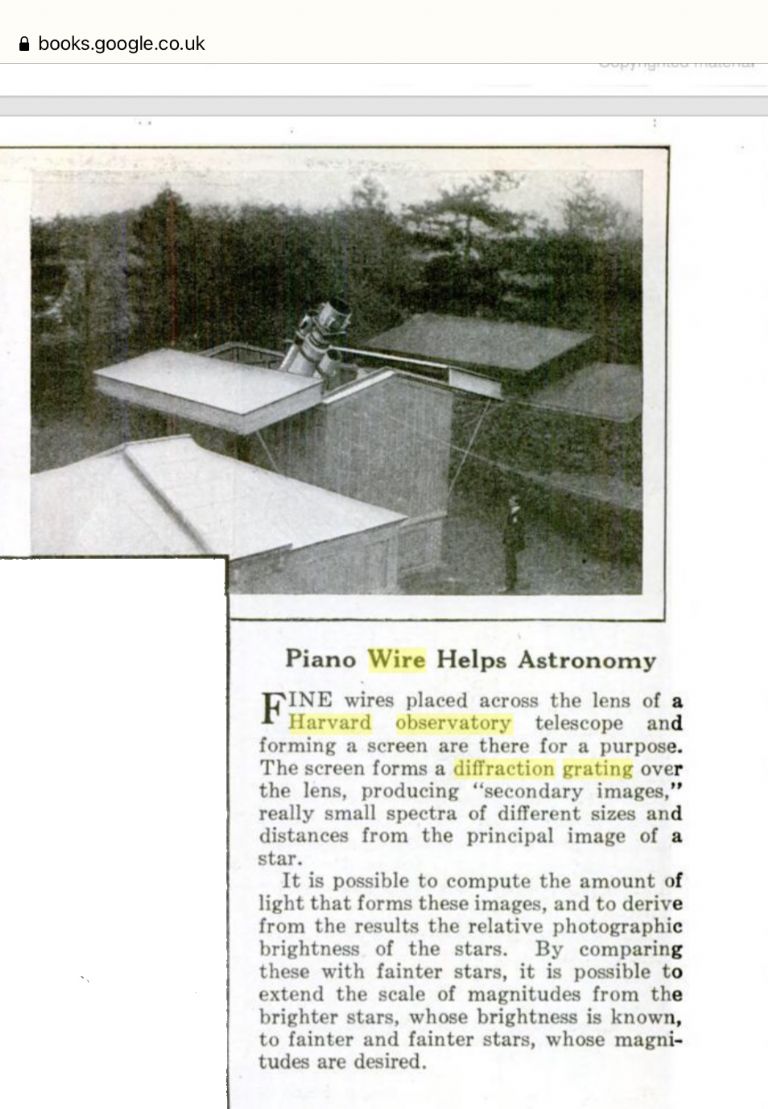

Looking closely, each pair of adjusting pins controls three spans between two small pins. If I were making it, I'd have two adjusters, one length of wire and more small spacing pins. I guess that layout was found wanting because the wires sag. Breaking the grating wires into spans of three allows a lot scope for equalising the tension.

Also, as Michael suggested, seems considerable trouble has been taken to put the pins neatly on circles. As only the height spacing matters, perhaps it's been done to emphasise the staggered adjusting pairs. Must have been annoying to accidentally twiddle adjusters on different spans.

Another mystery is the detector originally used with the grating? The spacing suggests infra-red or lower, which is invisible to the human eye. Sensitive semiconductor IR detectors make the job easy today, but weren't available when the grating was made. Considering the technical limitations of a hundred years ago, a lot of very clever experimental science was being done.

Dave.

Michael Gilligan.

Michael Gilligan.