Posted by Peter Simpson 3 on 04/12/2022 13:22:33:

Do these generic indexing plates allow you to do 32 tooth wheels ?

Are you asking of the rotary table ones or the dividing head ones?

The dividing head is a copy of the Browne and Sharpe one and the plates supplied will be the same as with that head. The newer Vertex was also a B&S copy and instructions for that, which includes the hole circles of supplied plates, are available (https://www.chronos.ltd.uk/wp-content/uploads/BS0-DIVIDING-HEAD-MANUAL-SCTOOLS.pdf).

For 32 divisons on a 40:1 head, you need 40/32 or 5/4 of a turn or 1 1/4. Any hole plate that is a multiple of 4 will do the job. At worst, count the holes shown in the photos of the Vevor plates. Hint, try the second-but-innermost circle of the plate that is mounted on the machine.

If you are asking of the rotary table, the 6" Vertex one is 90:1, so you would need 90/32 or 45/16 or 2 13/16. Hence, you need a 16 hole plate.

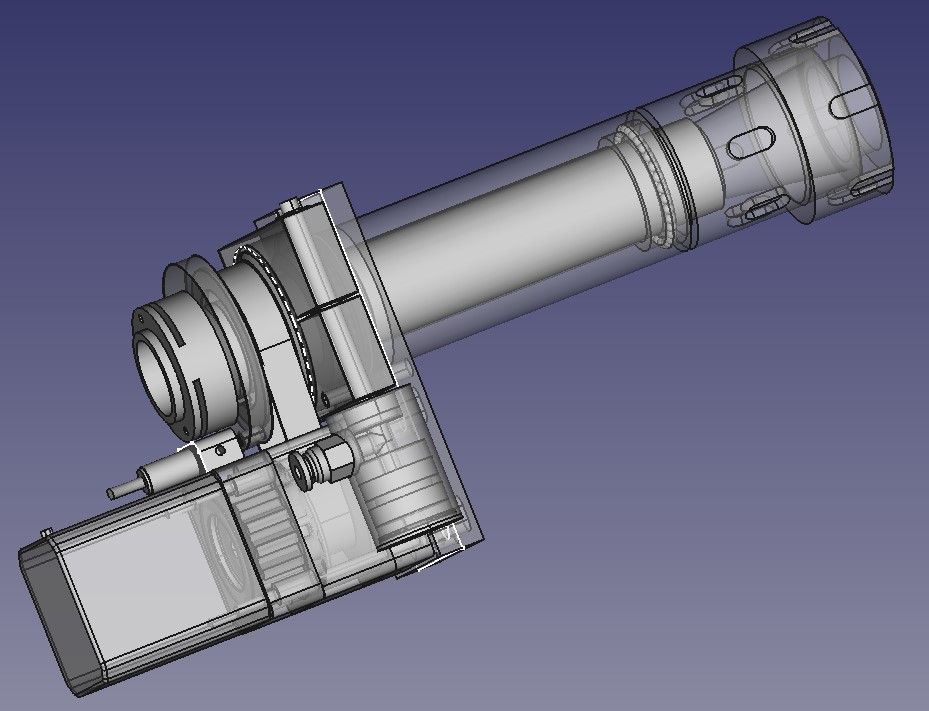

You state the helix angle as 10 minutes. Do you mean 10 degrees? Rather than a dodgy clamping setup, make a sub plate that bolts properly to the dividing head and then clamp the assembly to the mill table at the correct angle.

Robin.