Hi Marcus,

Not necessarily in the same order that you put…

My machine had exactly the same bearings as yours, not as in the manual.

I haven’t looked into it, but I have a suspicion that headstock bearings for the C3 lathe may be the same – see Arc Euro Trade website. If I am correct, then I seem to recall Dave Fenner changing them (on the C3 that is) and describing it in MEW somewhere.

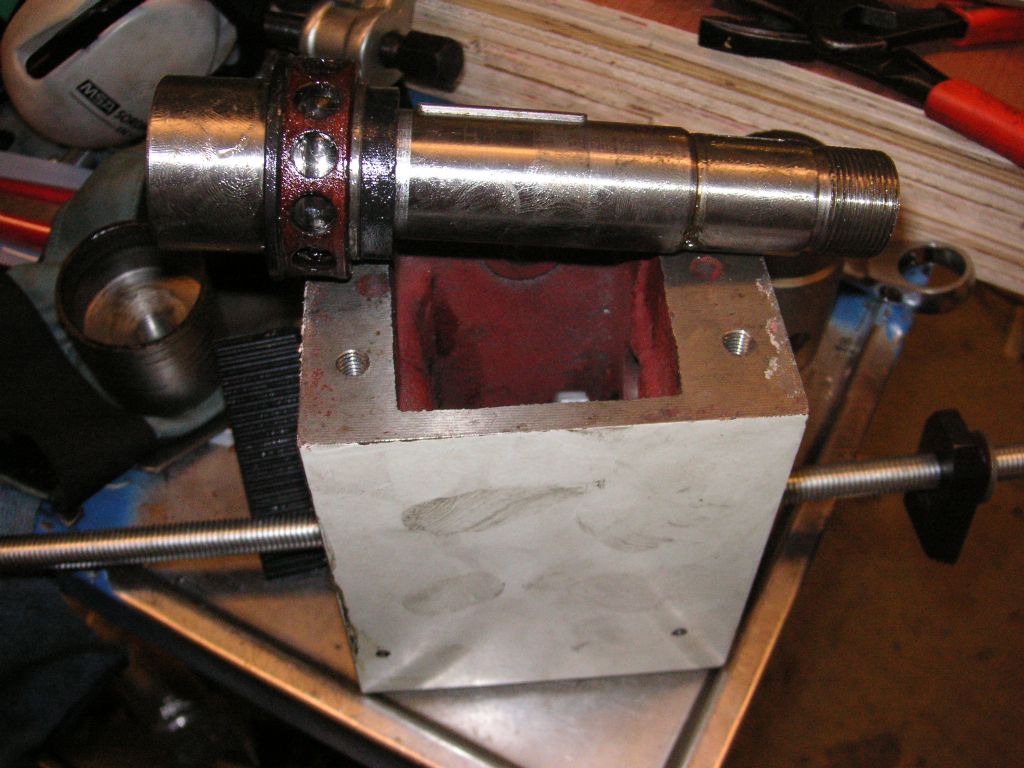

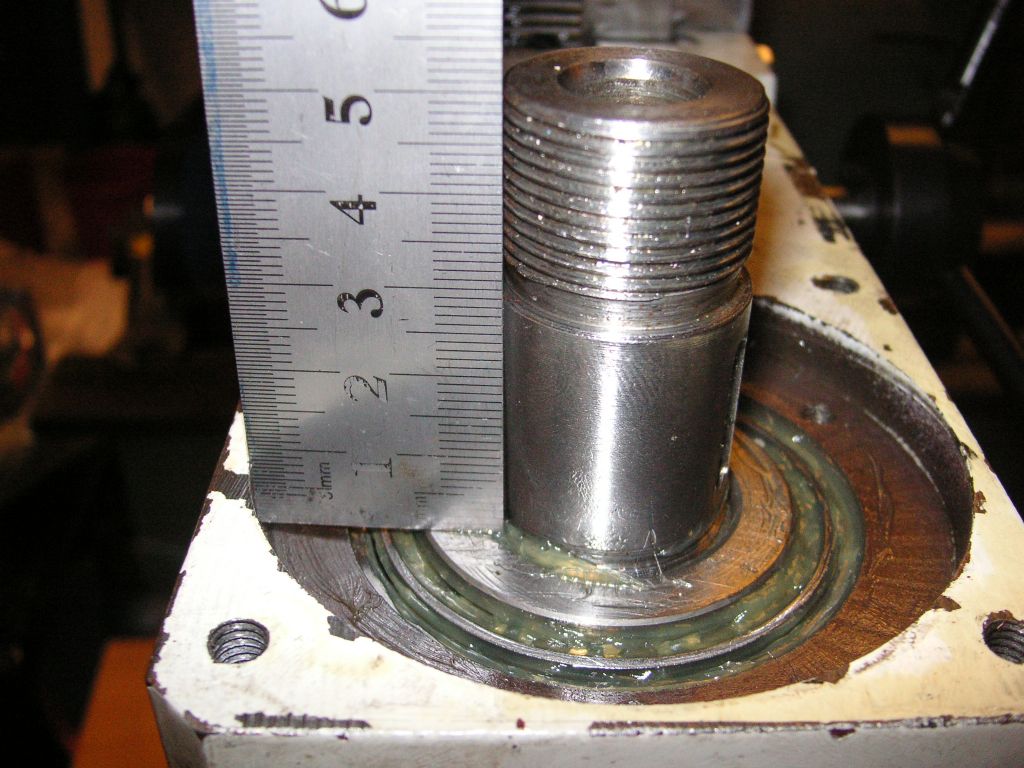

Now, I notice from your photos that the bottom bearing (7206AC) has come apart during the disassembly. Mine did not, ie the complete bearing came out with the shaft. However, a friend of mine has the same mill, Warco MiniMill, and only last week had to replace his gears. Just like you, his bottom bearing came apart. Now, I am not an expert, but it doesn’t seem right to me that these bearings should come apart like this. They are, after all ball bearings and I thought that once assembled they should stay assembled. I am aware though, that on bicycles that various ball bearings do in fact dismantle quite easily, but I think these of ours are meant to be sealed. Anyway, if you do succeed in changing to taper rollers then please let us, especially me, know because when my gears next break, I will wish to change them.

You comment on a lack of grease. This is exactly what my friend found, but I do not remember on mine.

Stripping the machine down is reasonably easy, even without the gear puller as you have. We changed my friends gears for metal ones that I had in stock ready, and reassembled in less than one day. It’s just a case of being logical.

Now onto the fine feed mechanism.

Your message above leads me to suspect that you do not know how it is meant to work. Please forgive me if this is wrong.

The finefeed knob via the long shaft turns the worm wheel inside the support block, item 159. This in turn rotates the bevel gear, item 155. This is shown in your photograph. The drive from the bevel gear is via the dog teeth onto the triple hand lever, item 154 which slides backwards and forwards along the pinion shaft item 157. The hand lever item 154 remains in either of two positions by means of a ball bearing item 149 (held by spring 150 and screw 151), there being two indentations in the end of the pinion shaft 157. Drive between the hand lever and the pinion shaft is by means of the keyway item 156.

So, to engage fine feed, the triple hand lever is pushed in towards the headstock to engage the dogteeth. The fine feed knob thus turns the triple lever slowly. To disengage finefeed, the triple hand lever is pulled out.

On both my mill, and my friends mill, the fine feed did not work. The manual did not even mention it, and it wasn’t until I downloaded a document from the Little Machine Shop in America that I found out how to make it work. What my friend and I discovered is that there is a gross misalignment between the the support block and the bracket adjacent to the fine feed knob such that the support block requires shimming out along its front edge (as you look at it from the front). Furthermore, the support block housing is too short for the actual worm itself, causing binding of the worm inside the block. This is cured by, in my case, adding washers between the end cover plate and the support block thus giving clearance for the worm to rotate. In addition, my friend discovered that his was seized up due to gunge.

Regards,

Peter

Clive Farrar.