Make sure the console is a universal one then.

I don’t have much experience of this, but some i know are milling consoles, some are lathe ones, and some are universal.

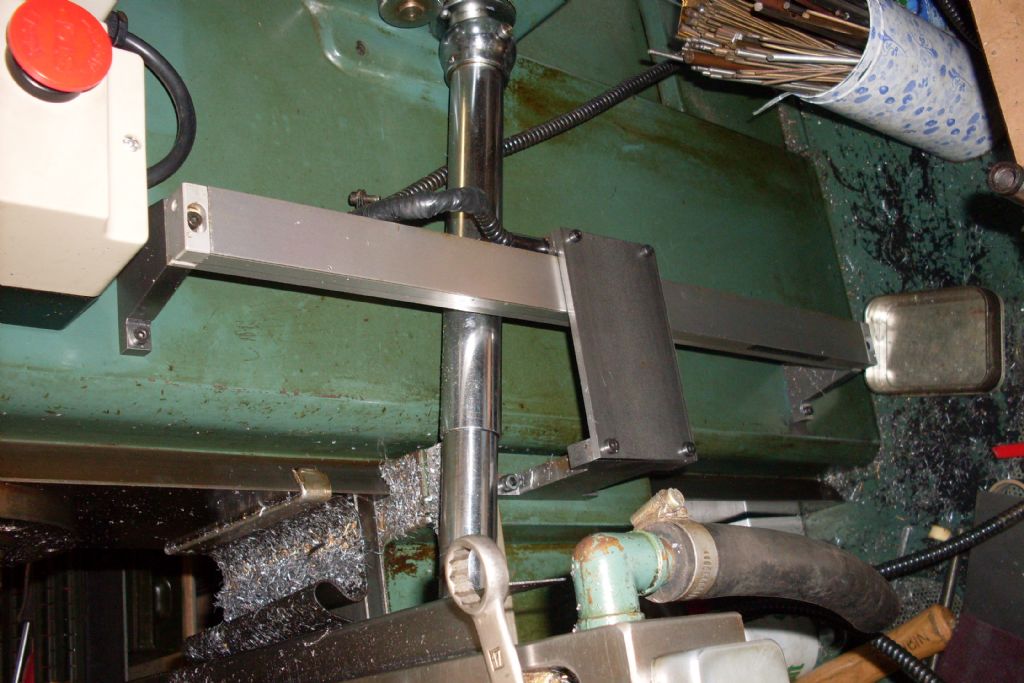

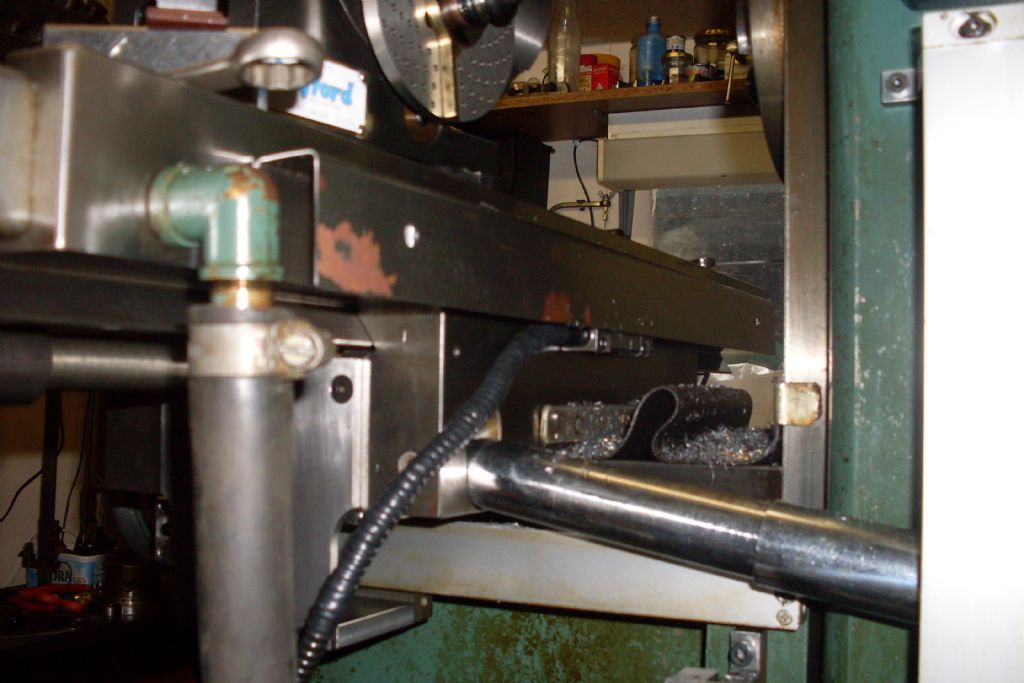

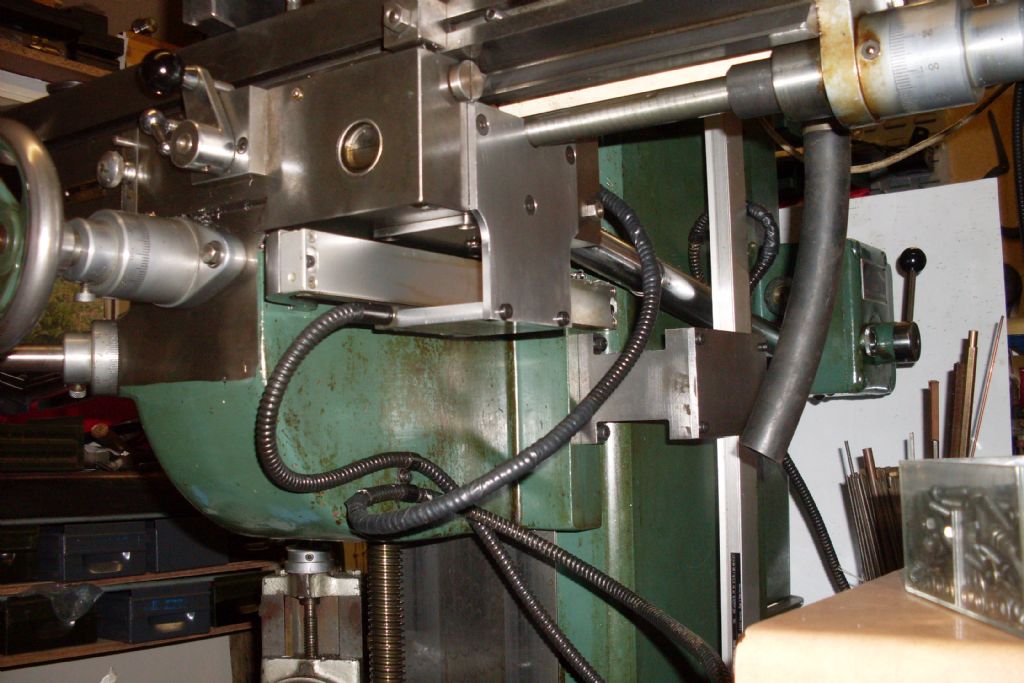

I set my Warco Supermajor mill up. I just read the instructions, ensured that all was set up well within the tolerances quoted for mounting the scales and fitted them with decent covers. Ensured the head carriers were good and well (miles) over solid and won’t flex. Works brilliantly and is accurate to .0002″ though the spec say +/-.0008. To mill to 2 tenths is fine by me.

I shall fit one to my big lathe, which is an Engineers Toolroom 1236, but I’ll use a dedicated readout. The idea is fine I suspect, but in practise the hassle of constantly entering setup and rejigging, wouldn’t for me, make swapping a viable exercise. Not as a normal occurrence. Its a pain going in, entering the correction for each scale in parts per million, sense/direction, beep on/off, diameter or radius etc.

I accept its not a long exercise, but it is a PITA every time you swap.

So I shall use two of the economy boxes.

Frank Dolman.