Design of boilers

Design of boilers

Home › Forums › Workshop Techniques › Design of boilers

- This topic has 107 replies, 27 voices, and was last updated 20 April 2021 at 09:17 by

Luker.

-

AuthorPosts

-

2 March 2021 at 17:35 #531262

Howard Lewis

Participant@howardlewis46836It is not the knowledge of any form of engine, but the application of logical thought that solves problems.

It is far too easy to pursue some obstruse feature when thought about basic principles will lead to a solution.

You might well design and construct a boiler which is theoretically correct, but soon declines in performance because of scaling. on the outside of the tubes, and soot on the inside.

The boiler on 71000 was a poor steam raiser until the ashpan was opened up to improve primary air flow.

Even a good boiler can give mediocre performance if managed incorrectly, fed fuel for which it was not developed, or supplying cylinders with less than optimal steam passages and valve events..

The Holcroft / Gresley 2:1 valve gear wasgood, but deteriorated rapidly once wear in the linkage occurred.

And don't mention Bulleid's chain driven valve gear and it's behaviour, or his steam reverser!

Witness the locomotive interchange trials carried out by various UK railways. A boiler developed to work efficiently with Yorkshire coal and over the home metals would not produce equal results when fed with Welsh coal and run over a different roadbed. And if the firing and driving techniques are different, so will be the results!

The K Class "River" tank locomotives were dangerous on their own metals , (The Sevenoaks accident ) but were considered to be safe when tested over LNER metals; because the roadbed was was better.

Holcroft found that a lot of his tests on locomotives ( Locomotive Adventure vols 1 and 2 if you want to see more detail ) yielded inconsistent results because of oil being carried over from the cylinders and being carbonised in the blast nozzle, as well as thermal expansion changing the relationship between nozzle and petticoat pipe.

There is a huge shoal of red herrings just itching to start swimming and confusing the results of any test.

Howard.

2 March 2021 at 18:05 #531267Nick Clarke 3

Participant@nickclarke3Posted by Bob Worsley on 02/03/2021 16:38:22:Conclusion, forget trying anything different.

My thoughts are simply that to run a boiler in public in the UK it either needs to be an existing design or where (unspecified) calculations are accepted by a boiler inspector and the whole thing accepted as sound design. If outside their experience they are perfectly entitled to refuse to test it, not because it is necessarily unsafe, but quite rightly because they are not familiar with any similar designs.

If I want to build a model locomotive then my options for experimentation are limited to non-existent if I want to run it in public and how many of us have private tracks that match up to those at many clubs?

As such this topic, while intellectually stimulating maybe, has little practical relevance in my case.

3 March 2021 at 10:05 #531373Luker

Participant@lukerI’ve been following this thread with great interest. Thanks for the mention Nigel but I don’t consider myself an engineer… still have a ways to go.

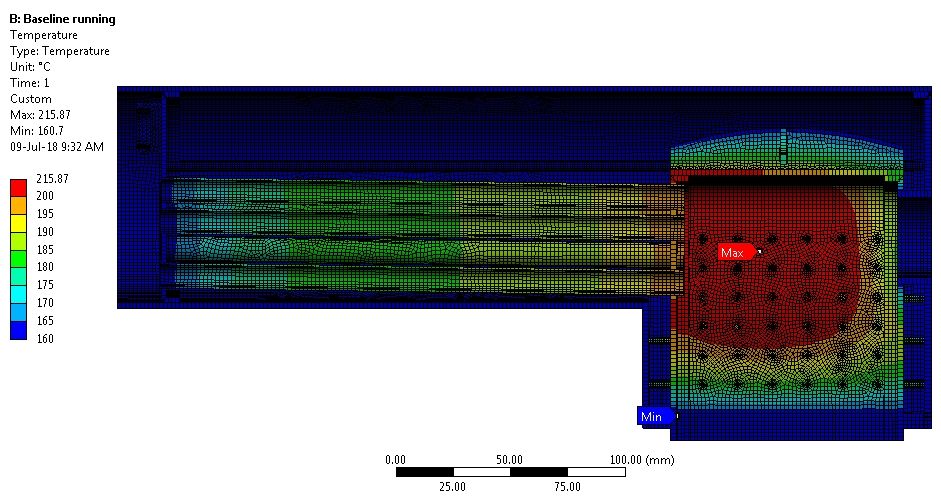

My two cents worth… Thermal radiation depends on the assumptions, with most of my simulations based on grey body radiation, the formulation for the emissivity is adjusted using first principles to account for specific conditions like dust, and build up on the thermal pickup surface. I’ve found with the boiler simulations that using straight black or grey body assumptions results in the heat transfer to the water being over-predicted. The view factor is calculated in the FEA, a little computationally intensive but you only need to do it once for a specific model. This is relatively new, a few years back this was a hand calculation typically using a solver in excel (not difficult just takes a while to setup).

There are many experiments for onset on nucleate boiling with some of these results shown in textbooks; worthwhile to have a look at. The non-dimensional analysis used in HE design is based on these early experiments with the calculations and formulations really just curve fitting. Perfect for water/steam which is what most of the experiments were done on.

I agree with Noel, just build it and try not to overthink! For the boilers and locos I design I do the initial calculation and simulations to decrease the build time and to make sure I’ll be happy with track performance, but I make sure it doesn’t keep me out of the workshop for too long! I have built a Martin Evans loco with the boiler doing the job on the track, but the designs were I’ve put a little effort in heat transfer and flow dynamics is orders of magnitude better (I can’t take credit for this, the computer did the work!).

The attached picture is from a slide show I used in a presentation, I wanted to upload the whole slide show but I’ll spare you all the HT FEA jargon.

3 March 2021 at 11:06 #531387Nigel Graham 2

Participant@nigelgraham2Oh, you deserve credit for the physics and maths!

The computer does not know how to analyse the physics of a miniature locomotive boiler – you need tell it how. You still need know the sums and how to tell the computer to do them for you.

Taking a GCSE Mathematics evening-class course over 20 years ago as a refresher for work reasons, I was baffled by the one topic new to school maths, hence to me: Matrices – taught as a pure abstraction linked to nothing else. I sought help from one of the scientists at work. Surprisingly, despite her PhD in Very Hard Sums, she could not explain the basic information I needed, so I was still baffled. She did though tell her work involved gigantic simultaneous-equation blocks soluble only by matrices; so I now knew their use – Finite Element Analysis (of vibrations, in her field). I realised the computer just made the arithmetic feasible. Though using a bought-in programme, she still needed to understand FE Analysis and extremely advanced mathematics.

As for the Matrix… It know the sort that is the clay in what used to be called "Boulder Clay"!

3 March 2021 at 12:11 #531404Nick Clarke 3

Participant@nickclarke3Nigel – Although I have never needed to use matrices since leaving University many years ago I do remember on lecturer (or maybe he was an instructor in a maths workshop?) explaining the need for them as follows –

You always had squared exercise books for maths in school and calculations were less confusing and easier to follow correctly if you kept to the squares. Well a matrix is the two or three dimensional equivalent for more complex calculations. Thank goodness I never met matrices with more than three dimensions then!

Worked for me for as long as I needed it to.

3 March 2021 at 14:06 #531432noel shelley

Participant@noelshelley55608The OP asks many questions and raises many interesting points ! When steam engines were used as transport, they seldom went cold, even quite major boiler repairs would be done as soon as it was possible for the boiler man and his boy to enter. Tornado had problems with it's boiler not withstanding all the technology and calculation used in it's design, I was dismayed to be told that a 9F in steam returning to the shed would not be steamed for 2 weeks. No matter how slowly you build up the fire from cold there will be differential expansion and stresses that would not normally have occured in it's working life – for which it was designed !

With all the volumes on the steam boiler and it's associated engine All the information is available to build the perfect boiler ! It should be possible using modern electronic control to burn the fuel and get the best possible efficiency for any given set of circumstances.

A light sensor in the fire box and another in the funnel to control fuel delivery and combustion air, integrated into the requirement for power. Constant monitoring and control of water level fed from a feed water heater, no sudden rush of cold water. Pressure monitoring and control of fuel to make safety valve lifting and power wasting a thing of the past. A sensor in the steam pipe to monitor priming and increase super heating. This and much more fed into the ECU. ATC !

Or one could employ a good driver and fire man who knew the road !

If one wants to build a boiler does one build to prototype or use more modern design ? Does one build it to work well or please the rivet counter ? Do you build something the youngsters would appreciate the application of modern technology to or something that transports us back to our childhood ?

With copper and silver at near all time highs I cannot afford to build an experimental boiler ! I would invite the original poster to do so and give us the benefits of his investigations and design. Noel

3 March 2021 at 15:07 #531450Nigel Graham 2

Participant@nigelgraham2I'd never even heard of Matrices until that course, and I assumed they are a new invention. So I was quite surprised to learn of their very deep ancestry; but thought it amusingly appropriate that one of their 19C developers, a certain Prof Charles Dodgson, also wrote two other fantasies – the Alice novels.

I don't understand them because though only boxes of simple arithmetic "sums" their completely unintuitive, fancy terms are never explained. Any likeness to any real mathematics alive or dead is purely co-incidental, let alone to physical things. So I could find nothing explicable, analogous or exemplifying, for them.

I'm afraid your lecturer's analogy is even worse than the introduction in the maths text-book. Having shown a simple table supposedly representing a shop's weekly sales figures, it stated that you could omit the headings naming the goods as long as you keep their order consistent…. then it launched straight into the mysticism!

Why couldn't my scientist friend not help me understand the basics of what she used at professional level?

She gave me what the teacher and books gave: the basic instructions. Not what matrices are and do to each other; not what "determinants" , "identity matrices" , etc. are. Nor why, when and where anyone might want to bundle little sums into three boxes, instead of writing them separately, and so on.

'

When it comes to designing the boiler for my steam-wagon, from almost nothing but a few photocopies of contemporary photos of the extinct vehicles, I used the standard formulae in the model-engineering books. That was for structure, not steam-raising power – I knew that would be beyond me even if I could find the methods.

However these do not give the strength-formulae I particularly needed, for the vertical, cylindrical inner firebox; a copper drum 5" diameter and about 12" tall, with most of the tubes lying along projected chords. I found something close in a professional designer's book written by an American chap called Roark, as well as discovering his tortuous formulae were governed by further "If A < B but >C where C > D" style equation chains.

Doubts set in when I saw at a major exhibition, a sectioned locomotive boiler failed before it had even seen its 7-1/4 " g frames. It wasn't my noticing the tube-plate flange bowed in by a desperate attempt to "planish" the shell down to meet it, but my I realising the builder had been unable to put enough heat, and rapidly enough, into the metal for the flux and silver-solder to work properly. Big cauliflowers of partially-decomposed alloy…

The clincher came at one of the Taunton MES exhibitions. 'Western Steam' trade-stand displayed a brace of freshly-made Shay loco boilers almost identical in pattern to my steam-lurry's patented form. Upshot of the conversation with Helen Verrall was my posting the dimensioned outline drawing to her, and duly collecting the finished boiler at the following year's exhibition. CE-marked, the lot.

Salient here was my asking for 4 superheater flues to give me the non-prototypical option (the engine is a compound but my replica is limited to 90pis boiler pressure), but otherwise I stated leaving all structural and fire-tube details to WS' methods and practice.

I still have my original boiler shell parts, machined, stored away in the loft in case I am tempted to try to finish it. The difficulty might be that of not frightening the society Admirers of Boilers with something not as conventional as a 6"-scale traction-engine or 0-gauge loco.

3 March 2021 at 17:07 #531473Luker

Participant@lukerNoel I’m with you on the cost of copper and silver solder, it’s ridiculous! But this is where modern manufacturing techniques, modern design and materials can bring the hobby back to where it was in LBSC’s time, suitable for the young and people with limited resources. I personally think experimentation on boiler design should be more towards materials and manufacturing techniques, with efficiency and steaming benefits a second thought (from my simulations and personal experimentation I think there is little to gain by digressing too much from the published ME ratios, for copper anyway). To put things into perspective not one of my last three locos cost me more to build than the price of a single set of Tich castings and they were all larger gauges.

Personally I’m too pedantic and safety conscience to have my boilers made by anyone else, professional or otherwise.

3 March 2021 at 21:12 #531508Andy Stopford

Participant@andystopford50521Posted by Nigel Graham 2 on 03/03/2021 11:06:17:Taking a GCSE Mathematics evening-class course over 20 years ago as a refresher for work reasons, I was baffled by the one topic new to school maths, hence to me: Matrices – taught as a pure abstraction linked to nothing else. I sought help from one of the scientists at work. Surprisingly, despite her PhD in Very Hard Sums, she could not explain the basic information I needed, so I was still baffled. She did though tell her work involved gigantic simultaneous-equation blocks soluble only by matrices; so I now knew their use – Finite Element Analysis (of vibrations, in her field). I realised the computer just made the arithmetic feasible. Though using a bought-in programme, she still needed to understand FE Analysis and extremely advanced mathematics.

As for the Matrix… It know the sort that is the clay in what used to be called "Boulder Clay"!

Matrices are much used in 3D computer graphics – a single 4×4 matrix can contain all the information necessary to Translate, Rotate and Scale an object, itself defined by it's transform matrix – how they do this is very non-intuitive, but computers seem to like it.

3 March 2021 at 21:44 #531517noel shelley

Participant@noelshelley55608If one was to present an accepted design of copper loco boiler to a club and the only deviation from spec was that it had been professionally TIG welded, with relavent certificates would it be accepted for test ? And if not why ?

Yet if it was built by an amatuer and silver soldered it would be ok !

With current costs for copper and silver will there be a movement towards small welded steel boilers ? I seem to remember in ME that someone did tests on the reative conduction of copper and steel and found that in REAL terms there was no significant difference, especially if one then used expanded copper tubes..

Any thoughts ? Noel.

Edited By noel shelley on 03/03/2021 21:45:28

3 March 2021 at 23:09 #531540Nigel Graham 2

Participant@nigelgraham2Thank-you. yes, I did discover the sorts of fields in which matrices are used, including graphics programming; but only much later. The course taught only their internal manipulations, no definitions, no purposes, no examples.

We would not have been what a "transform matrix" is or does, only how to transform it, perhaps.

I think computers like matrices because they suit the physical nature of the circuits.

'

My work-place sometimes took on work-experience students who then found the company's stock-in-trade unit, the decibel, hard to grasp because schools had no idea why anyone uses logarithms, so don't teach them.

The worst example of educated ignorance, though was told me by a scientist who asked a student to determine the real wind-speed and direction from its measurements on a survey-ship cruising obliquely to it. She thought it should be fairly straightforward for him, but he had to admit knowing nothing about trigonometry as he had never been taught it!

'

I recall my nephew once stating you don't need to learn much maths because you have calculators. I asked him, "How would you know what you are trying to calculate and how to do it, and so know what to enter in the calculator?" He could not answer that one.

Best not ask him to calculate a boiler shell strength then….

4 March 2021 at 07:17 #531557 JasonBModerator@jasonbPosted by noel shelley on 03/03/2021 21:44:20:

JasonBModerator@jasonbPosted by noel shelley on 03/03/2021 21:44:20:If one was to present an accepted design of copper loco boiler to a club and the only deviation from spec was that it had been professionally TIG welded, with relavent certificates would it be accepted for test ? And if not why ?

………………………

Edited By noel shelley on 03/03/2021 21:45:28

The Inspector may want to see some evidence of weld design eg type of weld prep to give a sufficiently strong joint. Also stay spacing may need to be looked at, I know from the Aussie code that the "flat" area is taken from where any radius from flanging ends so having no flange for a welded joint would give a larger "flat" area requiring staying.

As the Welding is almost certainly going to have to be done by a pro then labour cost is likely to be higher than a few sticks of silver solder so I doubt it would work out cheaper than home building but should offer a saving over the cost of a professional boiler that is flanged and soldered.

4 March 2021 at 09:34 #531592Luker

Participant@lukerPosted by JasonB on 04/03/2021 07:17:14:Posted by noel shelley on 03/03/2021 21:44:20:If one was to present an accepted design of copper loco boiler to a club and the only deviation from spec was that it had been professionally TIG welded, with relavent certificates would it be accepted for test ? And if not why ?

………………………

Edited By noel shelley on 03/03/2021 21:45:28

The Inspector may want to see some evidence of weld design eg type of weld prep to give a sufficiently strong joint. Also stay spacing may need to be looked at, I know from the Aussie code that the "flat" area is taken from where any radius from flanging ends so having no flange for a welded joint would give a larger "flat" area requiring staying.

As the Welding is almost certainly going to have to be done by a pro then labour cost is likely to be higher than a few sticks of silver solder so I doubt it would work out cheaper than home building but should offer a saving over the cost of a professional boiler that is flanged and soldered.

One of my copper boilers was TIG welded, with the stays adjusted accordingly. The tubes were silver soldered as TIG welding here is a little more difficult and I doubt the results would be satisfactory on copper. That boiler is still going strong with many, many steaming days under her belt.

I am not a fan of any requirements for professional or welder certification for the smaller boilers. If the club boiler inspector is any good he would pick up welding problems just by visual inspection, especially if TIG is used. Whether intended or not, requirements like these just make the hobby exclusive. We actually had a professionally built steel boiler imported by one of our members from the UK. I was asked by our boiler inspector to have a look at the dissimilar welding techniques used on the tubes. Not something I would recommend on a boiler, but I said it would not result in catastrophic failure so the boiler was allowed to steam. Not 6 months later the boiler failed on the fire door ring due to poor root penetration. The member told me later that the only subsequent service from that “professional” supplier was lip service!

Personally, all my boiler designs are run past our boiler inspector. Weld root design, photos, material certificates etc. all become part of the data pack and this should be done even for the smallest boilers. My view is if he finds something he’s not happy with, he’s helping me in the long run. You most certainly don’t have to be a professional to do a good job…

4 March 2021 at 09:43 #531597Nick Clarke 3

Participant@nickclarke3Posted by Luker on 04/03/2021 09:34:42:I am not a fan of any requirements for professional or welder certification for the smaller boilers.

In the UK a non-coded welder needs to submit recent weld samples to professional inspection to comply with the current boiler code in addition to the inspection by a club inspector. This applies to all welded boilers and the material (welded steel or TIG welded copper) is not specified.

See paragraph 6.2 here **LINK**

4 March 2021 at 10:00 #531604Luker

Participant@lukerPosted by Nick Clarke 3 on 04/03/2021 09:43:55:Posted by Luker on 04/03/2021 09:34:42:I am not a fan of any requirements for professional or welder certification for the smaller boilers.

In the UK a non-coded welder needs to submit recent weld samples to professional inspection to comply with the current boiler code in addition to the inspection by a club inspector. This applies to all welded boilers and the material (welded steel or TIG welded copper) is not specified.

See paragraph 6.2 here **LINK**

Thanks for the link, I've downloaded it and I'll go through it. Standard test samples are welded and tested to destruction for our club inspector as well. This is just good practice.

I'm curious, if you shake a cola can does the professional inspection authorities come running

4 March 2021 at 10:26 #531613

4 March 2021 at 10:26 #531613SillyOldDuffer

Moderator@sillyolddufferHow I empathise with Nigel's problem with Matrices, which is just one example why maths is difficult to learn and teach! Although interested in theory, I have a practical mind that sees little value in learning complicated stuff with no obvious application. I get bored.

The problem is that a great deal of mid-range mathematical techniques are building blocks, not obviously useful in themselves. Textbooks illustrate matrices with simple examples, which seem to complicate sums for no particular reason. I remember thinking at at school quadratic equations were an interesting puzzle with no application, and switching off. More fool me.

You have to accept mathematical building blocks pay off when advanced problems are tackled later. As one of my books casually mentions: Many equations are apparently not quadratics are reducable to quadratics by a suitable substitution. Suddenly the advanced student, having been taught to solve apparently useless quadratics, discovers they help solve difficult problems like finding the radius of a large pipe with two small rollers and a pile of slip gauges.

Likewise matrices don't make much sense manually, but become super-powerful whenever a calculation involves manipulating tables of data and/or tables of formula. For example a 2D CAD object defined as a series of X,Y coordinates can be transformed, rotated and mirrored with ordinary methods, but by a quirk of mathematics, it turns out the 2D calculation is done more efficiently by a computer in matrix form. And another major advantage appears when the CAD package has to transform X,Y, and Z coordinates in 3D. In matrix form, the 3D calculation is similar to 2D, whilst conventional formula applied to 3D transformations become downright clumsy and inefficient. Then, if a 3D object is moved in time, i.e it exists in 4 dimensions, the conventional approach suffers another painful explosion of complexity, which the matrix form doesn't. And best of all, matrix calculations can be parallelised in hardware, making matrix calculations super-fast. Note that most of these advantages are low value to a chap using paper and pencil methods.

As most home engineering doesn't involve much calculation of any sort, it's not obvious why matrices are a jolly good thing. We're like a canal bargemen: they have no need for advanced navigational aids such as compass, radar, GPS, chronometer, sextant, and a nautical almanac. Learning to use them is a waste of his time. A blue water sailor does need advanced methods, and anyone planning to land a probe on Venus is obliged to do even harder sums! Engineering is the same: building to a plan or assembling components requires practical skills; the need for theory and advanced maths kicks in when original design is required. Not many of us do original design because we copy existing practice. Bob's thread is interesting because he challenges that: I think he's on to something in that a thoroughly well-optimised design should perform better than approximations, but it's likely the approximations in existing boiler design aren't far wrong. The improvement might be tiny, or like Tornado, the modern implementation could be noticeably better than the prototype. (Partly achieved by improved dynamic balance, achieved by number crunching with a computer. Arthur Peppercorn would have done it in 1948 but he didn't have a computer to do the huge number of calculations.)

Dave

4 March 2021 at 10:27 #531614Nigel Graham 2

Participant@nigelgraham2There's nothing in the MELG rules to say you can't present a professionally-welded boiler, in copper or steel, with its paperwork, to a familiar design, to a club boiler tester.

The difficulty is that the welder might insist on the copper being "phosphorous de-oxidised" – I don't know the metallurgy in detail but this is the grade for welding. It does not matter for silver-soldering. Consequently it may well be easier and perhaps not significantly more expensive to have the whole thing supplied professionally, and indeed there is at least one manufacturer in Britain, of welded copper boilers.

However, there are also anecdotes of club boiler-testers declining boilers needlessly, and it would not surprise me if one refused to test a boiler made in the way you say, merely for it not matching his misunderstanding of the rules. (One is said to have rejected a boiler because its builder had increased the firebox wall thickness! I think another objected because the feed clack bushes were in better and more prototypical locations than drawn. )

Whilst moving to steel boilers may give sizeable material cost savings, I think in the UK at least much of that saving would be wiped out by the bureaucracy. The regulators and insurers between them have basically made it impossible for any but professional boiler-smiths to supply and build completely, to costly certification schemes for material, fabricator and assembly.

I think it is time we in the UK started to look at alternative (not necessarily replacement) materials. Cost apart, I cannot see a convincing reason not to use stainless-steel or silicon-bronze of their appropriate grades for the application – but whilst the bronzes are stronger than but can be formed and silver-solder in the same way as pure copper, I think the selection and welding of stainless-steel very much for the professionals. The real objection is the greater cost of these more exotic materials.

4 March 2021 at 11:18 #531620Luker

Participant@lukerPosted by Nigel Graham 2 on 04/03/2021 10:27:58:I think it is time we in the UK started to look at alternative (not necessarily replacement) materials. Cost apart, I cannot see a convincing reason not to use stainless-steel or silicon-bronze of their appropriate grades for the application – but whilst the bronzes are stronger than but can be formed and silver-solder in the same way as pure copper, I think the selection and welding of stainless-steel very much for the professionals. The real objection is the greater cost of these more exotic materials.

Going back to the roots of this thread, the Wahya boiler is a 4.2l stainless boiler designed using modern materials and modern heat transfer design techniques. The cost of the boiler was 170GBP (just converted the receipts). What is of particular interest is the grate size (which is small) relative to the cylinder swept volume, and yet it’s an incredible steamer on our poor quality coal. I TIG welded the boiler myself and am by no means a professional (I don’t do it for money) or qualified (no papers) welder. My personal view is anyone capable of a fine model has the ability to master welding with little effort. It’s sad that bureaucracy is limiting development in the hobby (in the UK).

4 March 2021 at 12:59 #531642 JasonBModerator@jasonbPosted by Nick Clarke 3 on 04/03/2021 09:43:55:Posted by Luker on 04/03/2021 09:34:42:

JasonBModerator@jasonbPosted by Nick Clarke 3 on 04/03/2021 09:43:55:Posted by Luker on 04/03/2021 09:34:42:I am not a fan of any requirements for professional or welder certification for the smaller boilers.

In the UK a non-coded welder needs to submit recent weld samples to professional inspection to comply with the current boiler code in addition to the inspection by a club inspector. This applies to all welded boilers and the material (welded steel or TIG welded copper) is not specified.

See paragraph 6.2 here **LINK**

Better still is to have the actual boiler welds no destructively tested for a modest fee which should be accepted, thread on here where that was done.

This boiler was home welded steel and cost less than £200 for materials and ND testing, insured via usual club insurance so Nigel has it a bit wrong about the red tape preventing it from being done, it is more down to how few home builders can do a good welding job

Edited By JasonB on 04/03/2021 13:05:02

4 March 2021 at 16:19 #531683Nigel Graham 2

Participant@nigelgraham2Luker –

I agree with your sentiments entirely but unfortunately our hobby became swept up in the European Union's 'Pressure Equipment Regulations', and the legal definition of 'work'.

The PER, in its English-law manifestation, seem written by and for lawyers who have heard of 'welding' and think all pressure-vessels are of aluminium or stainless-steel. The legal requirements are mainly trade-controls and to keep 'Notified Bodies' (test laboratories) rich, but include "…is, in fact, safe" – at the end of the list!

The PER apply only to boilers made and "placed on the market by way of trade". So the professional boiler-makers have to obey the rigmarole of certificates, Notified Bodies and CE mark (being replaced in the UK by a new, non-EU, one). Implicitly, we amateurs can still make our own boilers as we wish from the materials we think appropriate, according to the PER, as long they are, in fact. safe! And we can sell them, as privately-owned property, but not as traders.

A trade-built boiler pre-dating the PER is still legal. It has only to pass normal boiler-tests.

'

Now , we are also victims of precedent.

A few years previously the Health & Safety Executive (HSE) decided that clubs offering miniature-railway rides to the public are "fairground attractions" needing to be under professional show-trade equipment rules on design, construction, testing, maintenance and use of said equipment. This could have crippled or even destroyed the hobby.

Naturally, we expressed collective dismay. I attended for my society a meeting between clubs and Her Majesty's Principal Inspector of Fairgrounds (for the HSE).

Fortunately HMPIF was a reasonable chap who understood our predicament.

He explained the legal point that by inviting the public we are "at work", despite no-one being paid in cash or kind, we are under a 'legal duty of care' (DOC); and need to be able to show we are discharging that responsibility "as far as reasonably practicable". It means as well as engineering precautions, preparing Risk Assessments and records of operation and maintenance of society equipment… and taking the recommendations those show up.

He said something very important: "You are not building nuclear power stations!"

In other words, use common-sense, don't stifle yourselves with self-generated paperwork.

'

Hence the umbrella committee, the Model Engineering Liaison Group (MELG), representing from the various society federations, insurers and HSE.

MELG created the boiler test regime so engine-owners and club boiler-testers can follow the DOC and PER; keep the insurance-business happy – and be safe! (The Book of Procedures, bed-time reading only for insomniacs, could be better arranged.)

So, the DOC includes that our engine boilers are safe and can be shown as such, as far as practicable.

As stressed at Northern Federation of Model Engineers meetings I have attended, if your club can show it has done its best to protect members and visitors, then it is far less likely to be a victim of a spurious insurance claim (some try but are rebuffed); and if the worst happens the "man in the curly wig " is much more likely to be sympathetic in Court.

'

PER does not say who may or may not design and make welded boilers, but they lay down material, fabrication-inspection and skill requirements too stringent for most but fully-trained, coded welders to follow; and the insurers can only insist on the rules.

'

I say the MELG boiler test book is not easy to follow. It and the certificates seem designed as confusing as possible. This has led to tales of nervous society boiler-testers ( volunteers free to decline to test a boiler unfamiliar to them) "failing" perfectly good boilers through not understanding the rules properly. That though is their, and their clubs', fault. They are not supposed to fail equipment without good reason.

Finally I did not say the rules ban a home builder welding a boiler, just that the requirements make it nearly impossible.

'

I own a 7.25"g version of LBSC's Juliet . Its boiler is its second, is of copper; the last built by Reg Chambers. The loco was built originally as a club project, with a steel boiler made by a professional welder with no steam-loco knowledge, using ordinary seamless tube and hot-rolled mild-steel plate of unknown provenance.

The steel boiler had expired in service after 20+ years' hard use, quietly extinguishing the fire by a corrosion hole in the (unstayed!) firebox. I cut it open. The firebox was badly corroded, not helped by the gauge-glass bottom nut being below the crown. The rest was in fair condition. That was before material certificates etc,, but the boiler was tested annually under a simpler though effective system.

I wonder what has been achieved by the red-tape…

Yet I have also been involved in failing a brand-new copper boiler of LNER pattern, built by a retired, professional copper-smith, faithfully to an anonymous drawing – oddly, he would not reveal its source. Lacking stays, the inner firebox had partially collapsed under the builder's hydraulic test to working-pressure. A very sad evening, and I think to his fledgling hobby.

4 March 2021 at 18:28 #531712Luker

Participant@lukerNigel-

Thanks for that background; it gives me a little insight into how the hobby is managed in the UK. All that red tape is bound to stifle innovation. Safety and common sense is incredibly difficult to regulate.

Thankfully our club has a spirit of helping the builders get the best loco onto the track, this includes the boiler. On the rare occasion a boiler is deemed not fit there are normally a number of club members offering to help fix the problem, especially if they see the boiler was self-built.

4 March 2021 at 19:35 #531719noel shelley

Participant@noelshelley55608Nigel, your right I was the victim of a boiler inspectors lack of understanding of the rules ! It cost me over £300. see post no6 in this thread. The only good thing was that I bought a beautifully built commercial boiler with every conceivable add on you could think of. It is still unused and to buy the add ons NOW would cost almost what I paid for it.

It was built in 84 so no CE mark It was based on a design good for 70 psi and OD 5". The whole thing was enlarged to 6" and heavily built. The original test was 2X Wp = 160psi Wp80psi Doing some calculations it would be good for 120psi even with a saftey factor of 8. The club ticket it was given was wp100psi INTERESTING ? Noel.

4 March 2021 at 20:15 #531727Andy Stopford

Participant@andystopford50521Posted by Nigel Graham 2 on 03/03/2021 23:09:22:Thank-you. yes, I did discover the sorts of fields in which matrices are used, including graphics programming; but only much later. The course taught only their internal manipulations, no definitions, no purposes, no examples.

…

I think computers like matrices because they suit the physical nature of the circuits.

Indeed. When I was suffering O-level maths in the seventies, there was no hint of any practical application for matrices, or anything else; pointlessness was regarded as a virtue – hence the fetishizing of Latin, that most useless of subjects (academic linguists are free to differ).

The reason that matrices are used in CGI is that a common construct in computer programming is the array, and a matrix is, essentially, an array, and can be manipulated using simple rules.

Human-friendly controls in the program's user interface essentially manipulate vectors which conceptually aren't as easy to represent in the computer's world. It has to convert them into lower level arrays to actually work on them.

To comment on the thread, from which we've drifted, I think its interesting to consider whether boiler design can be improved, even if the practical answer is that there's no point/it's as good as it gets already, or whatever.

5 March 2021 at 09:45 #531809SillyOldDuffer

Moderator@sillyolddufferPosted by Andy Stopford on 04/03/2021 20:15:21:Posted by Nigel Graham 2 on 03/03/2021 23:09:22:…

…

To comment on the thread, from which we've drifted, I think its interesting to consider whether boiler design can be improved, even if the practical answer is that there's no point/it's as good as it gets already, or whatever.

I agree!

I wonder what an engine specifically engineered to win IMLEC would look like. An engine with no obligation to resemble a full-size locomotive, or to be practical beyond winning IMLEC, and run in conditions that don't require the boiler to be certified.

I suggest:

- A tall vertical boiler balanced by outriggers

- Draught created by a tall chimney, not steam blast

- Waste steam used to pre-heat air intake and tender water

- Scale prevented by only running on distilled water

- High pressure, possibly from a water-tube boiler, with efficient superheat. (Isn't a water-tube boiler the logical conclusion to Bob's idea? It's all done with radiant heat.)

- If a fire-tube boiler is used, corrugate the firebox

- Oil burner to maximise heat and remove ash issues.

- Only burns one oil of known heat value so that combustion and heat transfer can be optimised.

- Grate area, firebox volume, and heating surfaces, calculated and proportioned to match the fuel and to optimise IMLEC performance.

- Large diameter steam pipes and a big steam chest

- Valve gear simplified to minimise friction

- Large aperture poppet valves, precision made to minimise leaks, possibly from exotic materials.

- Everything thoroughly insulated without regard to appearance!

- Optimum speed and load determined by experiment with a Dynamometer Car, and observed during trial

- Maximum automation allowing the boiler to control input and output to eliminate the possibility of a heavy handed driver wasting steam with excessive acceleration, or otherwise running the engine outside it's sweet-spot. Also manages combustion to best effect, neither underheating or overheating the boiler. Remote control and automatic shut-down

- Ideally driverless and without human passengers because they wobble, shift and raise the centre of gravity. Also, removing people means bigger risks can be taken with the boiler, speed, and balance.

- Thermal proportions, weight, adhesion, static and dynamic balance and other design features to be computer modelled to optimise performance

- Only run the engine under ideal track conditions – level, stiff track in good condition, few points, and large curve radii etc. And only run on dry, windless days.

Slight problem with all this! Lots of expensive development and build work, resulting in a zero romance, plug-ugly locomotive only run on very special occasions. Just a bit dangerous too, with a risk it might not significantly outperform an ordinarily good IMLEC contender. And if it fails to win the builder will be hideously embarrassed…

Dave

5 March 2021 at 10:00 #531810Andy Stopford

Participant@andystopford50521Go on, build one!

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Workshop Techniques › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

TurboCAD – Alibre File Transfers.

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 5

- 18

-

13 July 2025 at 23:37

Nigel Graham 2

-

Sat nag

1

2

Started by:

duncan webster 1 in: The Tea Room

- 18

- 36

-

13 July 2025 at 23:29

Martin Dilly 2

-

Variable DC power supply?

Started by:

Andrew Tinsley in: Electronics in the Workshop

- 4

- 7

-

13 July 2025 at 22:06

Andrew Tinsley

-

Boiler Design – issue 4765

1

2

…

7

8

Started by:

Charles Lamont in: Model Engineer & Workshop

- 26

- 196

-

13 July 2025 at 21:53

Charles Lamont

-

Indicators – vehicle

Started by:

Speedy Builder5 in: Electronics in the Workshop

- 4

- 5

-

13 July 2025 at 21:35

Robert Atkinson 2

Robert Atkinson 2

-

Silver steel crankshaft

Started by:

teamricky in: Stationary engines

- 7

- 15

-

13 July 2025 at 18:27

teamricky

-

Another Day … Another ScumBag

1

2

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 15

- 33

-

13 July 2025 at 17:42

Nigel Graham 2

-

Adjustable spanner thread direction

Started by:

jimmy b

in: Workshop Tools and Tooling

jimmy b

in: Workshop Tools and Tooling

- 9

- 9

-

13 July 2025 at 15:45

Martin Kyte

-

Electroplating questions

Started by:

Baldric in: Help and Assistance! (Offered or Wanted)

- 3

- 3

-

13 July 2025 at 13:42

noel shelley

-

buying machine tools from aliexpress experiences?

Started by:

Jake Middleton-Metcalfe in: Manual machine tools

- 15

- 19

-

13 July 2025 at 09:57

Russell Eberhardt

Russell Eberhardt

-

“swedish iron”

Started by:

moonman in: Materials

- 11

- 15

-

13 July 2025 at 09:47

Martin Kyte

-

Difficulty in sourceing 2.5mm s/s ‘Full’ nuts

Started by:

Greensands in: General Questions

- 7

- 12

-

13 July 2025 at 09:22

Roger Woollett

-

Rotary valve engine

Started by:

AStroud in: Stationary engines

- 2

- 3

-

13 July 2025 at 08:49

AStroud

-

Sanjay’s Banjo Engine

Started by:

JasonB

in: Stationary engines

JasonB

in: Stationary engines

- 3

- 12

-

13 July 2025 at 06:50

Diogenes

-

I’m Under Pressure

1

2

Started by:

howardb in: Related Hobbies including Vehicle Restoration

- 17

- 31

-

12 July 2025 at 22:00

Howard Lewis

-

Help for DIY lathe build.

1

2

Started by:

moogie in: Help and Assistance! (Offered or Wanted)

- 16

- 36

-

12 July 2025 at 21:42

Howard Lewis

-

Electronic leadscrew pitching error

Started by:

paulg 1 in: Introduce Yourself – New members start here!

- 2

- 6

-

12 July 2025 at 21:08

paulg 1

-

New Member From The Isle of Man

Started by:

sprocket 3 in: Introduce Yourself – New members start here!

- 4

- 4

-

12 July 2025 at 20:57

Howard Lewis

-

Farm Boy

1

2

…

4

5

Started by:

Dalboy in: I/C Engines

- 15

- 103

-

12 July 2025 at 18:51

Dalboy

-

The Silver Swan Automaton

Started by:

James A in: Related Hobbies including Vehicle Restoration

- 3

- 5

-

12 July 2025 at 18:46

James A

-

Model Turbines

1

2

…

24

25

Started by:

Turbine Guy in: Stationary engines

- 28

- 607

-

12 July 2025 at 16:28

Turbine Guy

-

Nozzle dot dwg

Started by:

Michael Gilligan

in: CAD – Technical drawing & design

Michael Gilligan

in: CAD – Technical drawing & design

- 1

- 1

-

12 July 2025 at 14:47

Michael Gilligan

Michael Gilligan

-

Yet another scam

Started by:

Dell

in: The Tea Room

Dell

in: The Tea Room

- 2

- 2

-

12 July 2025 at 10:16

Bo’sun

-

Chester Champion, warco ZX15 drawbar

Started by:

martian in: Manual machine tools

- 5

- 7

-

11 July 2025 at 21:51

Howard Lewis

-

Bosch PBD 40 bearing upgrade

Started by:

th1980 in: Manual machine tools

- 6

- 12

-

11 July 2025 at 21:33

Howard Lewis

-

TurboCAD – Alibre File Transfers.

-