My reaction was only dismal in the sense it recognises the difficulty of what Bob is suggesting. There are too many variables in play at the same time!

Existing model boilers are based on full-size practice reduced to meet the constructional needs of scale models. Whilst scaled down boilers aren't the result of a bottom up design, they've evolved over a century of practical construction. I suspect, despite imperfections and misunderstandings, they are a good practical compromise.

Reading about boiler design in the 19th century, it started with wild guesses and ended with boiler design based firmly on scientific understanding derived from experimental evidence. None of the experimental work was done on small boilers! When boilers are scaled down, the big picture disappears into the noise. I don't think the thermodynamics of small boilers are understood, because small changes of layout have disproportionate effects, and they have never been studied comprehensively. No-one knows!

Much easier to predict the behaviour of a 3" diameter 20 foot long fire tube than the same thing at 1/12 scale. This is why one builder of a small boiler reports 70% efficiency, whilst another has a red-hot smoke box. The difference might be explained by the fuel alone; welsh steam coal has a much stronger radiant effect in the firebox than wood or slack where still burning particles are often blown out of the chimney. Or the difference is caused by something else entirely.

Rather than building a boiler on Bob's principles and testing it as a unit, I suggest it would be better to test each idea one at a time. If an all at once unit behaves well, it's hard to determine why. Which of several features is working? Likewise a failure might be due to one big shortcoming overwhelming several small improvements elsewhere. But which bit is wrong?

Be good if Bob's ideas could be simulated with a computer model rather than expensively building and testing real boilers, but I doubt the mathematical properties of scaled down boiler components are sufficiently understood; they would have to be determined experimentally. Again, this would have to be done one at a time, a lot of work.

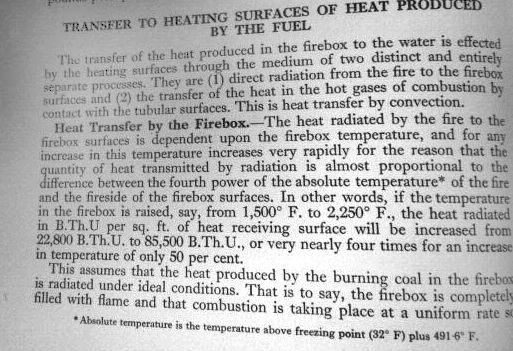

Bob mentioned the Stefan-Bolzmann law. Strictly speaking the law applies to Black Body radiation, which isn't exactly a model loco's firebox. It describes what happens when an incandescent object behaving as a 'black body' is viewed. The law is more appropriate to radiation escaping through an open firebox door than what happens inside. I mention it not because Bob is wrong to consider it, but because I don't know how to apply it in a simulation, or even if it's valid to try in these circumstances.

May be worth Bob modelling his boiler ideas with a 3D CAD package – Fusion 360 can do FEM, and I think it does thermal flows as well. However, getting the model right, applying the analysis, and interpreting the results are all skilled work. Not easy. Worse, I'm not convinced Fusion would model a miniature boiler correctly because its database of physical properties are all full-size. So it might be accurate for 60532 Blue Peter and unreliable for LBSC's Tich. Or maybe Fusion or another CAD modeller is smarter than I think!

More power to Bob's elbow though – this is unexplored territory.

Dave

Edited By SillyOldDuffer on 22/01/2021 11:24:25

Luker.