Posted by noel shelley on 09/02/2023 10:24:51:

Hey Hopper ! Nice work. What grey are you using ? Noel.

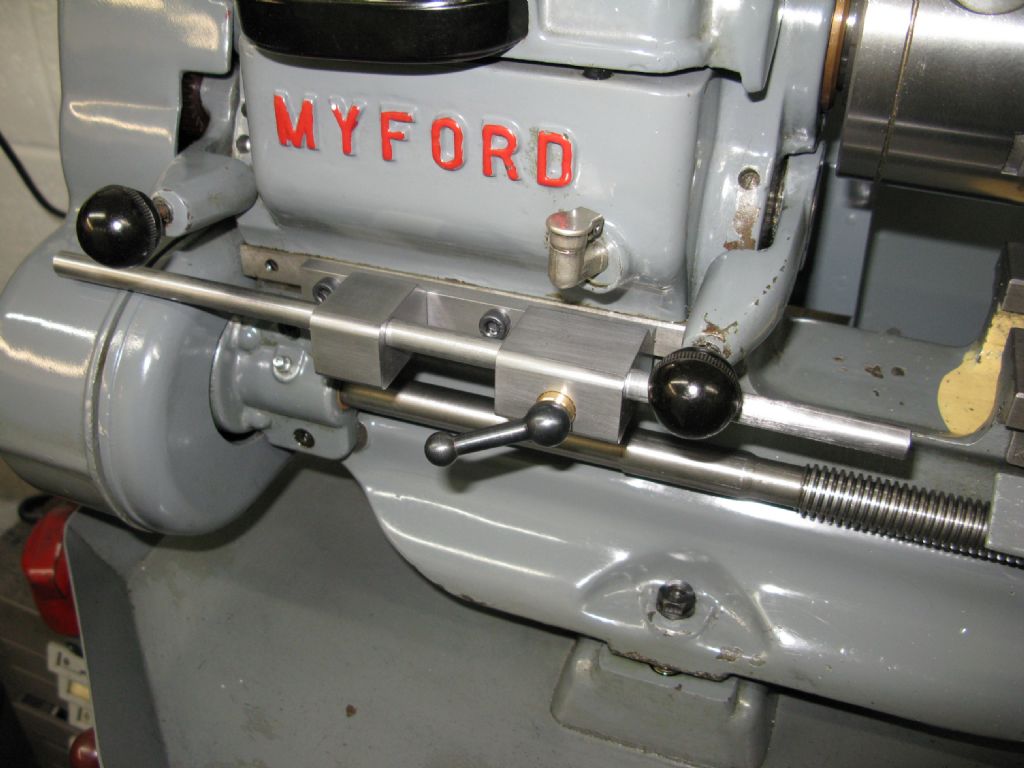

Thanks Noel. I did the old "faux casting" trick again to keep it looking original.

The lathe is painted in machinery paint mixed to paint code RAL 7011, "Iron Grey". It is actually a shade darker than the original Myford paint.

I think I painted that stop in rattle can Dulux colour "Machinery Grey" which is a tad lighter and closer to Myford original colour but not anywhere as near durable. So close in colour nobody really notices though.

The RAL 7011 is in real life a tad darker than it appears in these pics. The picture of the stop sitting on teh wooden bench top is closest to reality. Depends on lighting and computer screen calibration etc. But compared with the original-paint Myford dividing head and vertical slide I recently restored, the 7011 is definitely a bit darker, despite claims on various websites to the contrary.

I can't import Paragon paint etc due to hazardous freight regs etc so this is as close as it gets. But its a piece of workshop equipment, not a Rolls Royce Phaeton!

Edited By Hopper on 09/02/2023 11:01:44

Edited By Hopper on 09/02/2023 11:03:03

Martin Kyte.

![img_0828[1].jpg img_0828[1].jpg](/wp-content/uploads/sites/4/images/member_albums/181046/919153.jpg)