Threaded stud sounds a good way to go but in practice is over engineering things. Takes forever to wind the nuts up and down. My big Pollard 15 AY has a simple round rod with a split clamp on it. Loosen clamp, slide into position and lock. Much faster and easier. There is a deep engraved scale on the rod to hep setting but its not that easy to read.

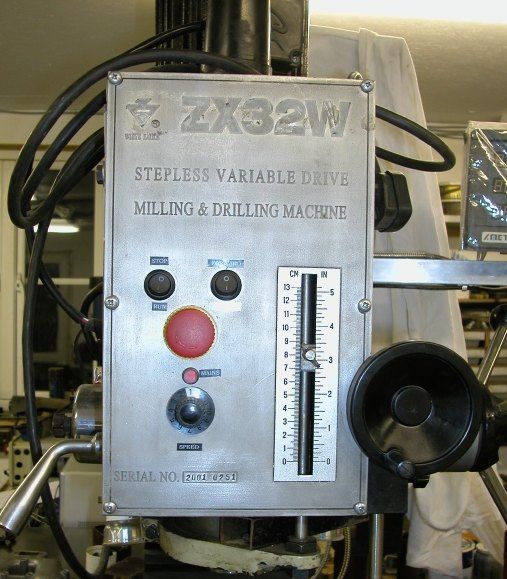

My experience is that scales on depth stop rods never get beyond sort of OK. The Chester Lux type mill I used to have came with a monumentally frustrating depth stop consisting of a threaded rod loosely fitted into a collar on the quill with a knurled rod underneath to turn the screw driving a Tee shaped nut up and down in a slot in the front panel of the head. Pointer on the nut indicated positions via a rather nice scale on the panel. The various clearances involved made setting very much a miss-miss-miss- hit or curse affair. I replaced the screw with a fixed rod, drilled the Tee nut out for a wing headed bolt so it could slide up and down easily. Put a copper slug under the bolt to prevent damage to the rod. Worked a treat.

.

.

I imagine something similar could easily be arranged by fitting a plate to carry a laser printed scale.

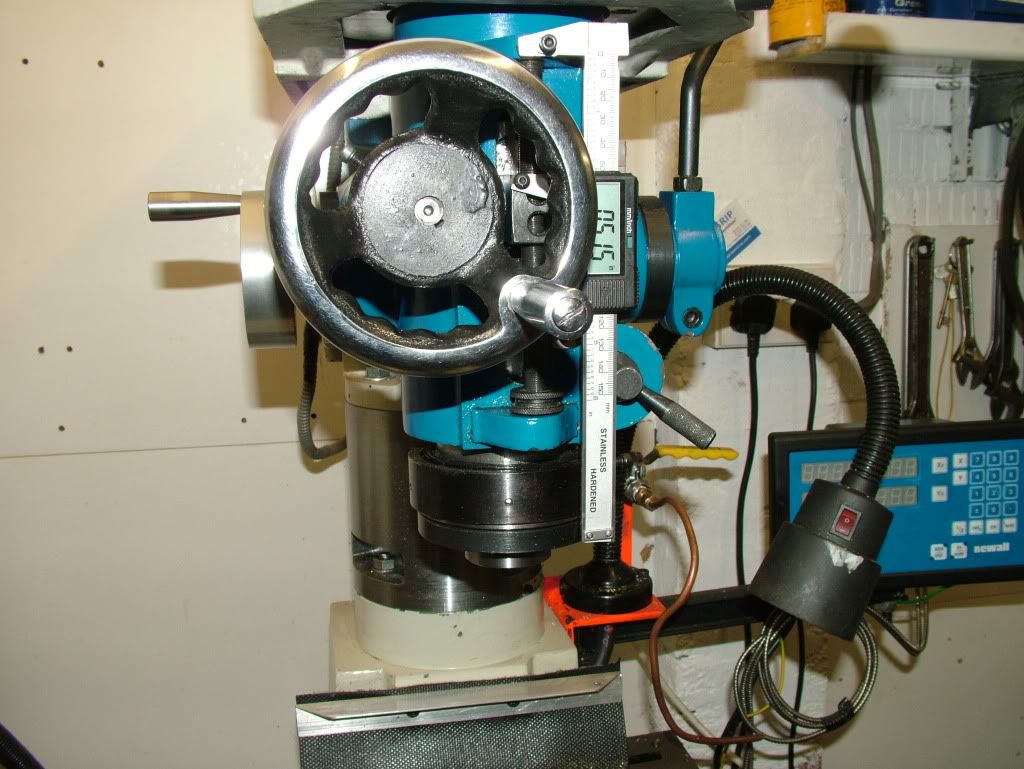

The need it now super fast scale bodge is to clamp an ordinary ruler or even pocket tape measure in position. Heard of one 3 cable ties and tape measure set-up that was used for several years in "I'll do a proper job when I get time" mode.

Clive.

PS poxy auto spell check!

Edited By Clive Foster on 16/12/2015 11:55:13

Edited By Clive Foster on 16/12/2015 11:55:39

Edited By Clive Foster on 16/12/2015 11:56:17

Edited By Clive Foster on 16/12/2015 11:57:16

edintheclouds.