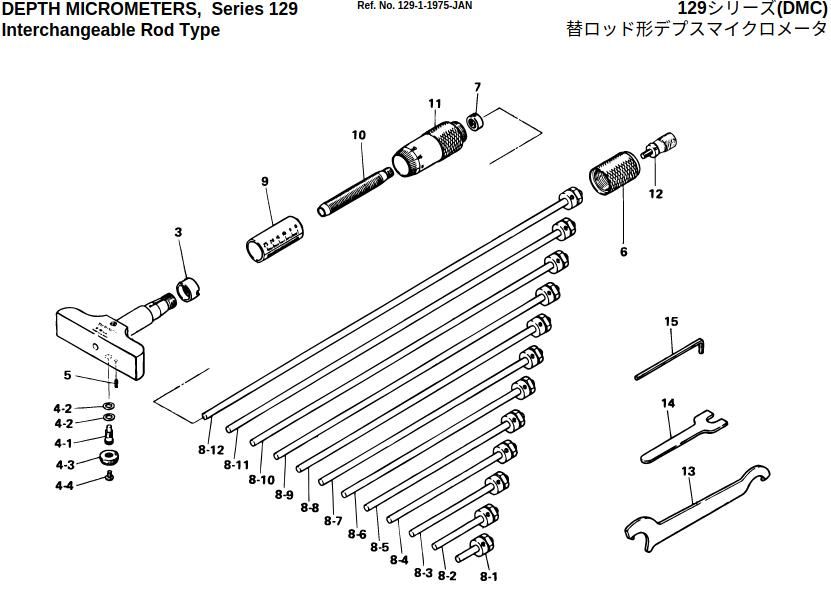

When I looked at one of my depth mics, I realised that the lock mechanism holds the depth rod, and has nothing to do with the micrometer thread 10. The collar 3 should be tightened back up in stages with the micrometer thread 10 screwed in halfway, tighten until resistance is felt and then back it off slightly until the thread feels smooth throughout its travel. With the nut 7 removed from 10, find the shortest rod and put it in place within 10 and stand the mic base on a flat surface. Then unscrew the thread 10 until it just touches the head of the rod. You then remove the rod and fit the barrel 11 with the zero in line with the inner scale. Take care not to turn 10 as you fit 11. Hold the parts together tightly on the taper as you fit nut 7. Then assemble with the shortest rod and screw on 6 finger tight. Check how close you are to zero using the flat surface. If you are close, a fine adjustment to the inner barrel 9 can be made by turning it, or if the zero is too far, then unscrew 7, break the taper and try zeroing again. This requires some patience, and luck. Hopefully, the rods will still be set, they are difficult to calibrate.

Before reassembly, you should use a spray degreaser (not water based) and lubricate the threads with light oil.

old mart.