Reading lathes co uk I get the impression it uses a separate 2 speed motor for feeds and yet another single speed motor for milling. It mentions that the max milling speed is rather low for smaller diameter cutters.

If so the milling motor might be dual voltage so could be driven directly with an inverter. Or if pure 440v a single speed motor could be driven with a Transwave unit. These are fine if the instructions are followed. An inverter would allow the max speed to be increased. I would have thought that increasing the original 1900 rpm to 2,850 by driving up to 75Hz would be fine. Personally I wouldn't go any higher than that but some do. A lot of people also go for a more powerful motor when they convert like this so that the power is still there when it's slowed down. Personally I never run mine below 40Hz. People do go lower but only for very short periods.

You could also fit a 240v motor and add some sort of pulley arrangement to get more speed.

If it does use a dual speed motor for feed you might be stuck with changing it to a singles speed and then lacking the faster feed rates or not having the slower ones. It is possible to buy dual speed 240v motors but they are rather expensive. Looking at these some time ago there may be more than one type in terms of HP at each of the speeds. Not sure about that aspect.

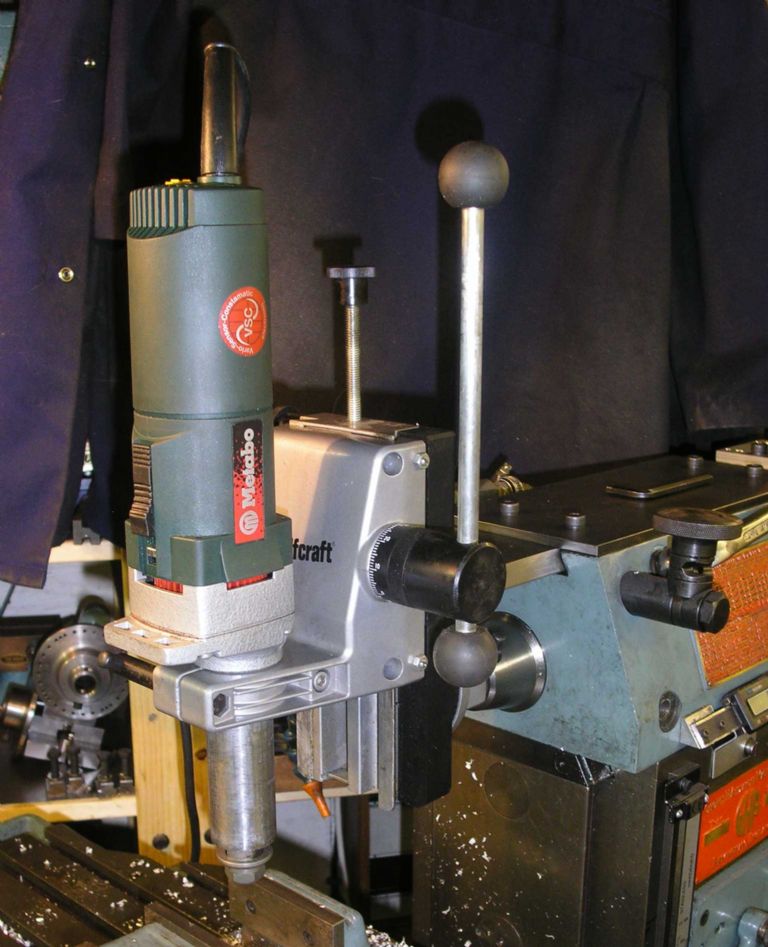

Deckel get round the high speed aspect by offering a different head with it's own drive motor. My guess is that they wouldn't be selling it if it had this and all was ok.

All that running small cutters at lower speeds means is slower feed rates really. If it's in good order I wouldn't let that aspect put me off. I would want both the horizontal and vertical heads – trying to find these used could be something of a problem. Some wouldn't be bothered by not having the horizontal head but they are more ideal for certain types of work. eg During training I made a V block on one that didn't show any improvement in accuracy after is was ground.

John

–

Brian Todd.