Sincere thanks for everyone’s replies.

Michael, sadly I can’t tell whether or not the removed gear has expanded slightly from new (though Howard’s and Jason’s numbers suggest it may have done) because I baulked at paying Warco’s £60 for a probably short-lived replacement , so I have nothing to compare with.

On

19 March 2024 at 07:51 JasonB Said:

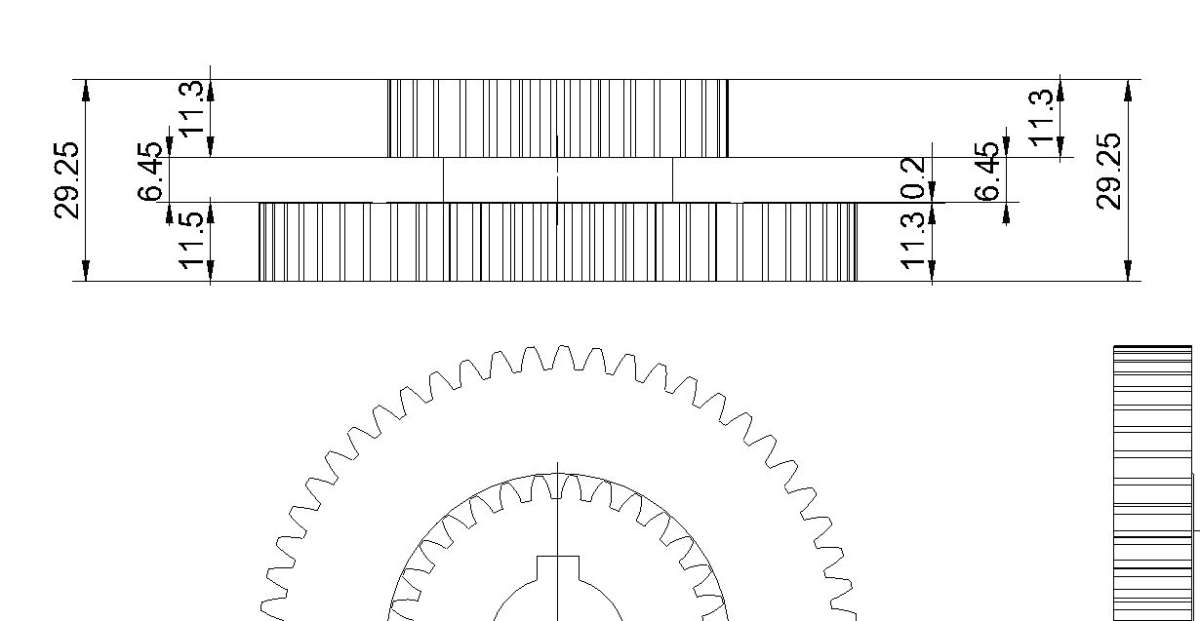

11.3 + 11.3 + 6.45 = 29.05, in my book that is more than 28.65. I’ll draw it for you but need numbers that work.

That’s right, Jason. I discussed this in my follow-up post (720691).

I don’t know how important the slightly raised areas are, nor how to describe them numerically, but maybe if the extra 0.4mm were distributed equally between the two cog thicknesses whilst preserving the given dimensions of the connecting/separating shaft there wouldn’t be too much of an issue. If I’ve read him rightly, DC31k does suggest a slight oversizing of the cog thicknesses may not be unhelpful.

On this subject – the apparently only partial-thickness-engagement of the low gear with the spindle gear (both on my machine and on all the other examples I’ve seen on the Internet of the same stripped gear) – I’m wondering whether this may be something to do with the positioning of the detentes in the gear selector plate, rather than, or perhaps as well as, with the thickness of the cogs.

I’ll try to explain. After my gear was damaged but still in situ, I noticed that whilst the high gear sat perfectly level with the spindle gear when high gear had been selected, the low gear showed a tendency to drop back down slightly once the my hand let go of the knob and the ball bearing inside had settled back into its relevant detente.

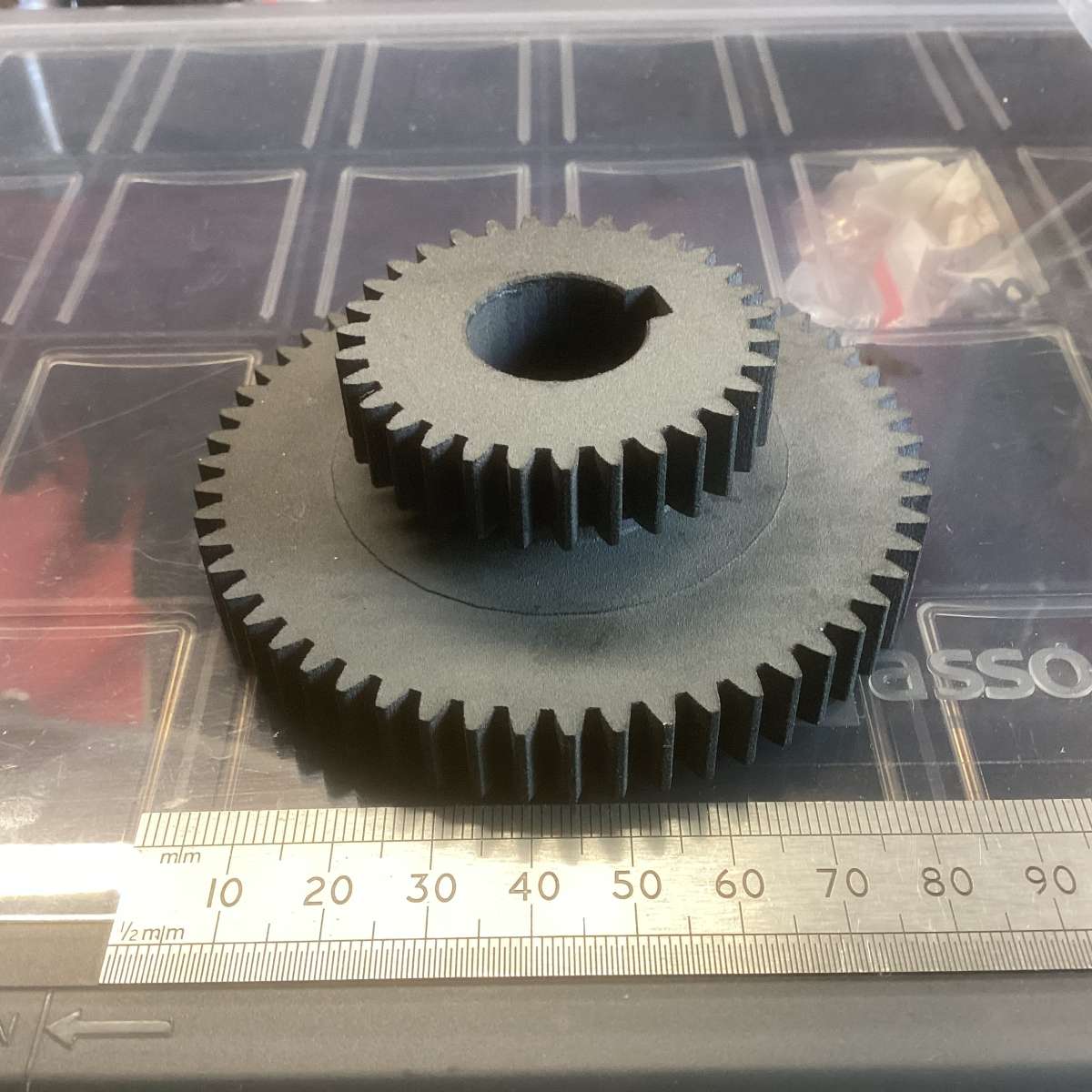

It was not very easy to be sure of this, though, because the mangled portion of the gear made it difficult to select low gear at all. By way of explanation, in the photo at the foot of this post showing the circular gear selector plate, you will notice that the detente for the low gear is considerably closer to the central detente than the high gear detente is. Is this a factor in the unsatisfactory engagement, I wonder?

What I’m planning to do, assuming I get a new gear of some kind made and fitted, is to see what gear selection looks like with the new gear and the existing gear selector plate. If the new low gear visibly drops back down slightly away from full engagement when low gear is selected and the selector knob is released, I think I will know with more certainty that the detente position for the low gear isn’t far enough away from the centre to keep the gear in the correct alignment. I will then set about making a new gear selector plate (probably from gauge plate) with the low gear detente countersink somewhat further away from the centre than on the present one.

Any further thoughts would be much appreciated.

Bill Phinn.