Ok it's been too long but this is where I am at…

At one point I had everything together and the clock would run for a bit and then stop. I found I'd you lifted the pallet, the gear train was stuck and giving the main wheel a jolt caused the weight to fall and the gear train to spin wildly.

I frustration i contacted Brian who was adamant that the problem lay with the teeth style. As a result I bought a cyclical clock tooth cutter and remade the gear train gears.

I was quite disappointed to find there didn't seem much difference only the the gear train seemed to have less rattle. Again I rebuilt the clock (less all the motion works) and again the same problem!! The gear train kept sticking

Now I did notice that one of my pinions didn't have perfect 45degree spacing of the pinion wires and this did cause a slight resistance when turning the wheel and so re-machined it (took a couple of goes to get it near perfect).

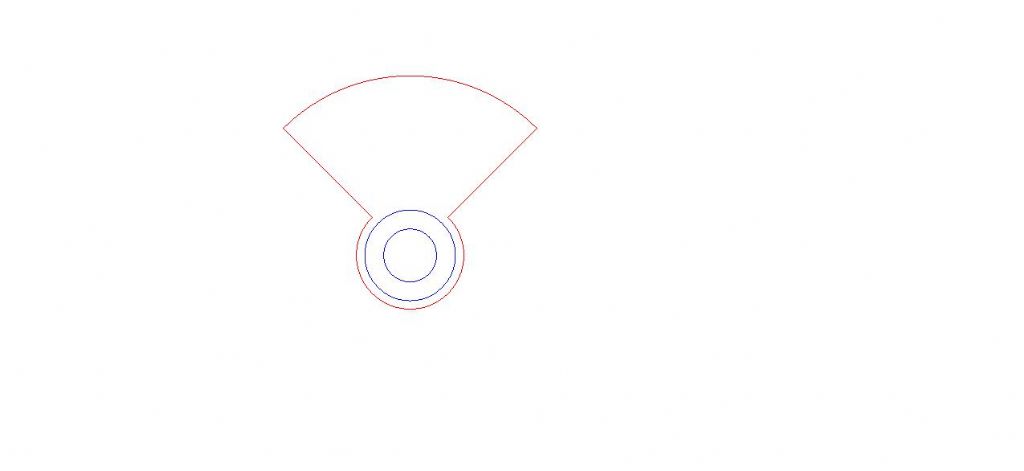

So back to the depthing gauge .. First off the main wheel and second wheel pinion. I could get free spinning with the teeth only engaged to a depth of the pinion wire. I have always thought that the pinion wire in a tooth gap should end up about half way. Adjusting the gap between the gears eventually causes the gears to bind/jam and increasing the gap does cause the gears to spin but there is quite a lot of play.

Again, I re-depthed the second wheel to the escape pinion and drilled the bushes to suit. To my utter dismay, I found the Gear train would easily bind and taking account of John C's experience elongated the Bush holes for the escape arbor to allow the bushes and arbor to be moved before bonding with super glue.

Now this time the gears turn really smoothly with hardly any effort on the main wheel and so yet again, fitted everything else. The result exactly as before random no ding of the gear train. What I did notice was that the escape wheel could be turned ever so slightly with the second wheel so I have concluded that the main wheel is binding with the second wheel pinion only when the load of the weight is added..

So where I am now is that I think that the main wheel to second wheel pinion is not meshed enough, it appears that I can reduce the spacing of the wheels by about 0.8 to 1mmm.

The trouble is I'm not sure what the optimum meshing should be I can only increase the meshing on the first two wheels and see if that improves the binding. When the clock was working the pallet/escapment seemed fairly regular so i think that part is OK.

I'm also debating (now i have remade the opinions) whether to go back to the invite gears i made (I noticed the teeth width using the cycloidal cutter is not very even compared to the involute which are spot on.

As i said Brian was adamant about the tooth shape but email communication appears to have stopped?

I am absolutely determined to get this working but there have been quite a few times where i was tempted to give up but i have invested a lot of time and money getting tools and materials and this clock is just a stepping stone for other peojects, so if i can't sort this out then there's little point trying to build anything else

John silver.