Margaret

The usual form of damage head screw remover devices aren't terribly effective on this sort of screw. The head is too soft for the grooved wotsit to get a grip. It generally just cuts out a cone.

The only sort of extractor for machine screws and bolts that I've found to be anything approaching universally reliable are the grooved pin and hex turning device type sold by Rigid, Snap-On et al at seriously high prices. Drill the bolt, drive the pin in and around 90% of the time it comes out. Hafta accept that sometimes things will be immobile. Way, way too speedy for one job but I've had my moneys worth over a quarter of a century!

The tapered thread easi-out variety can work but are very hard and notorious for snapping off if you apply too much torque or are bit off-line with the spanner. Once snapped you have a really hard bit left stuck in the screw making the problem much worse as it can't be drilled out with normal tooling.

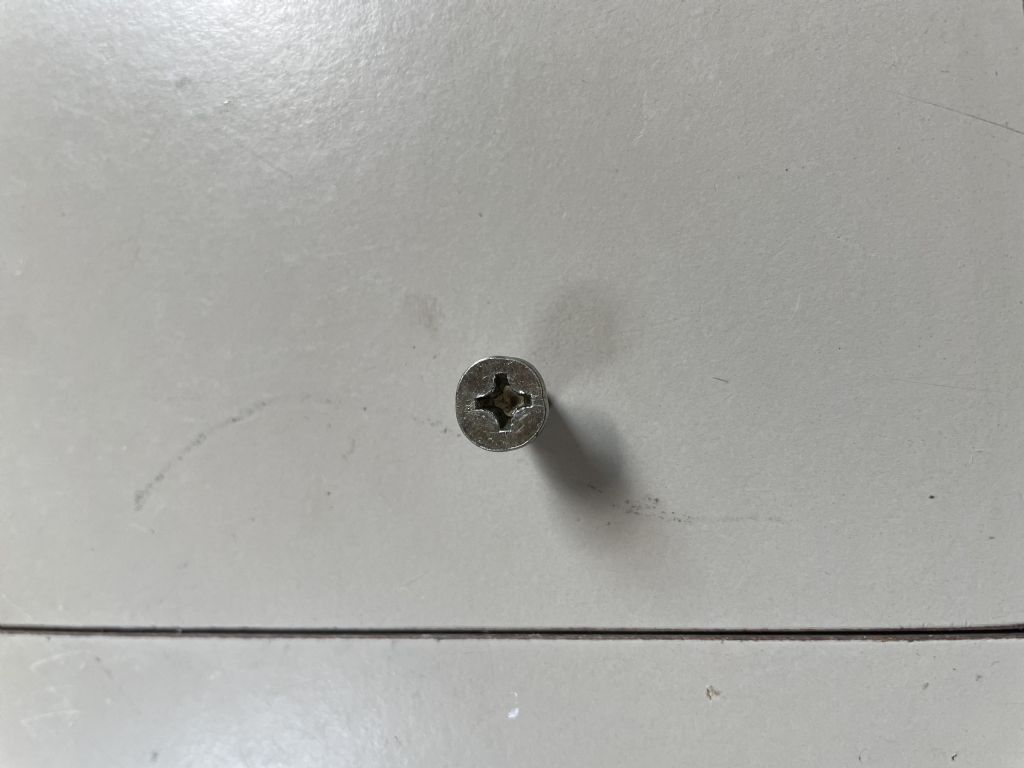

These days I just use a drill to take the head off in that sort of situation. I reckon your screws are M6 so 7 mm drill would do the job. With the heads off things can be separated and the sticking out stubs of the screws turned using a decent set of pliers. On relatively new stuff the threads are rarely jammed so the remains come out quite easily. Problem is usually due to the softish head being deformed when the screw is driven home by powered driver jamming it into the countersink. Slack fitting screws can cock over a bit inn then threads considerably increasing the amount of head jamming.

I recommend Maun parallel grip one for this sort of thing as the jaws are very well made and the parallel motion seems to give abetter hold than the usual pivot style. Spendy (£30 ish for the 160 mm flat nose ones I have) but good.

Clive

Edited By Clive Foster on 29/07/2023 15:37:39

Edited By Clive Foster on 29/07/2023 15:38:11

duncan webster 1.

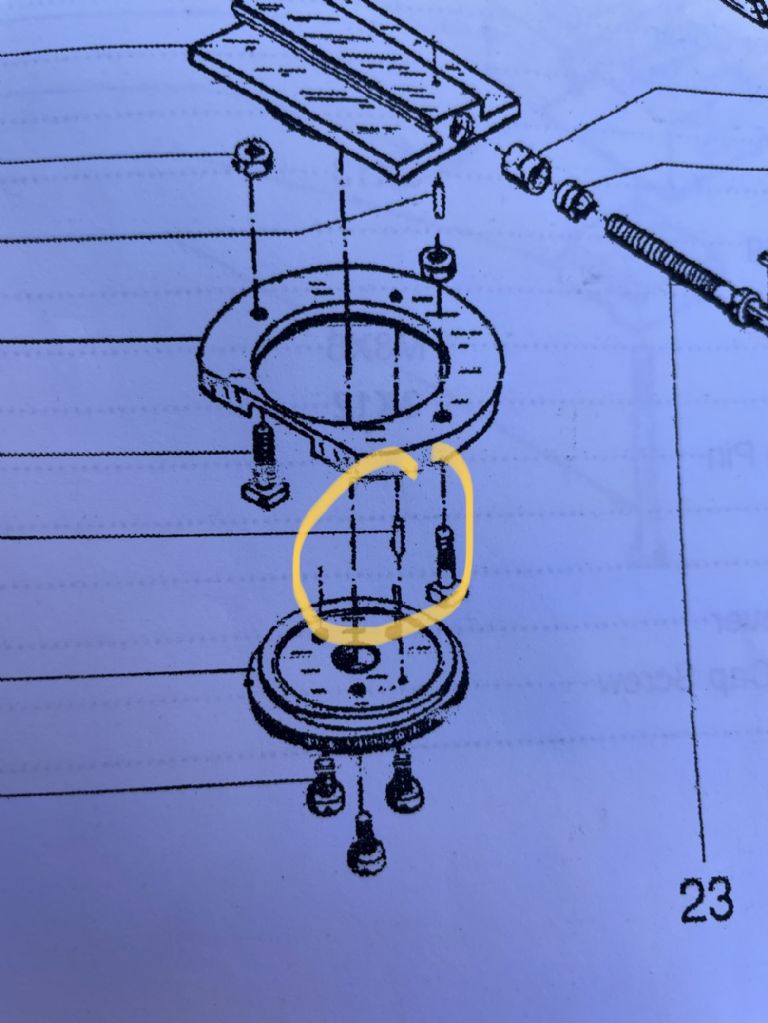

![20230729_182710[1].jpg 20230729_182710[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/926490.jpg)