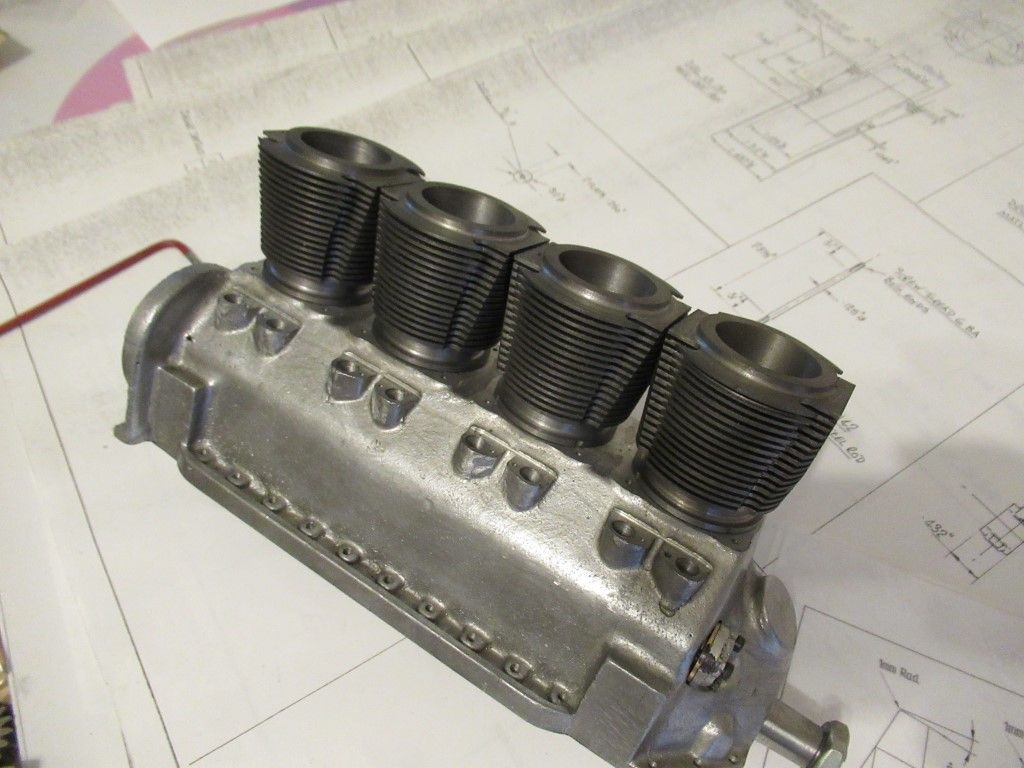

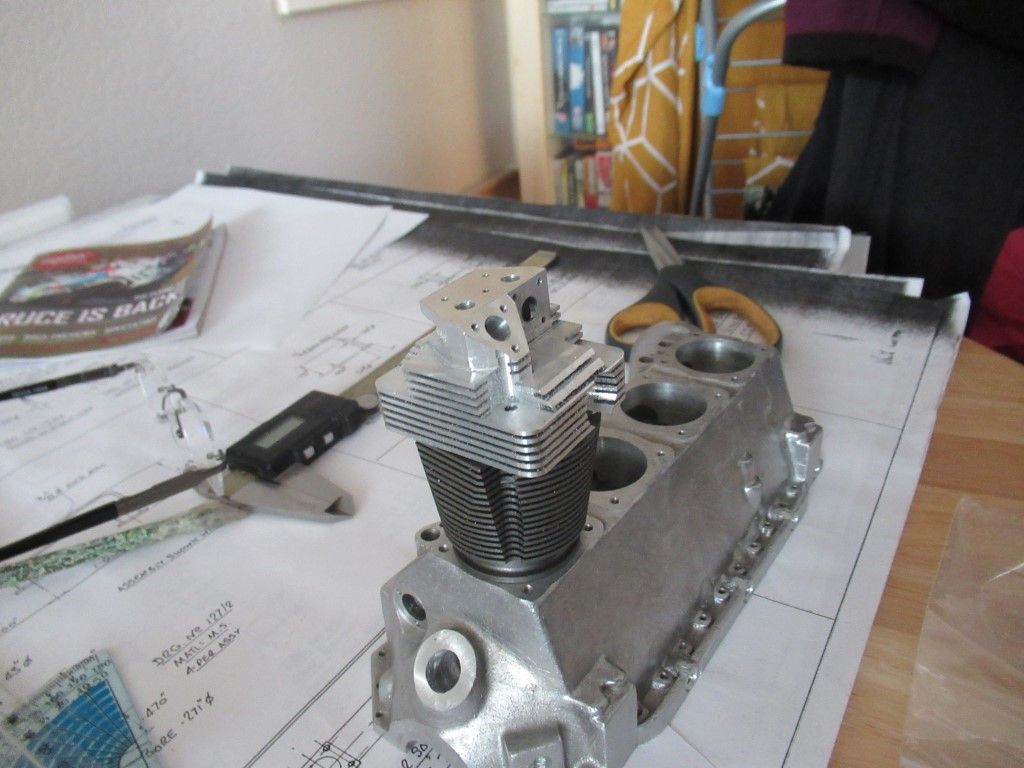

D H Gipsy mk1

D H Gipsy mk1

- This topic has 59 replies, 15 voices, and was last updated 28 November 2023 at 14:20 by

bernard towers.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Vice as Broaching Press

- New member old lathe

- Stripped aluminum threads. Now what?

- Safety Pickle for Steel

- HOBBYMAT MD65 – JAMMED

- Boiler Silver Soldering – Not gone well.

- Electric motor vibrations

- UK consumer protection laws?

- Zig Zag Crimping Tool for eg Resistor/ Capacitor Leads

- Powered hacksaw – blade lift for the return stroke