Hello Garry,

I have come to this thread a little late. Regarding the cylinder mounting studs, I have done this job twice now. I have a 2 inch Durham engine, now nine years into its second boiler (don't ask). The studs are fitted into through holes and sealed with Red Hermetite, and there has been no problem with leaks on either of the boilers. So this procedure will work OK.

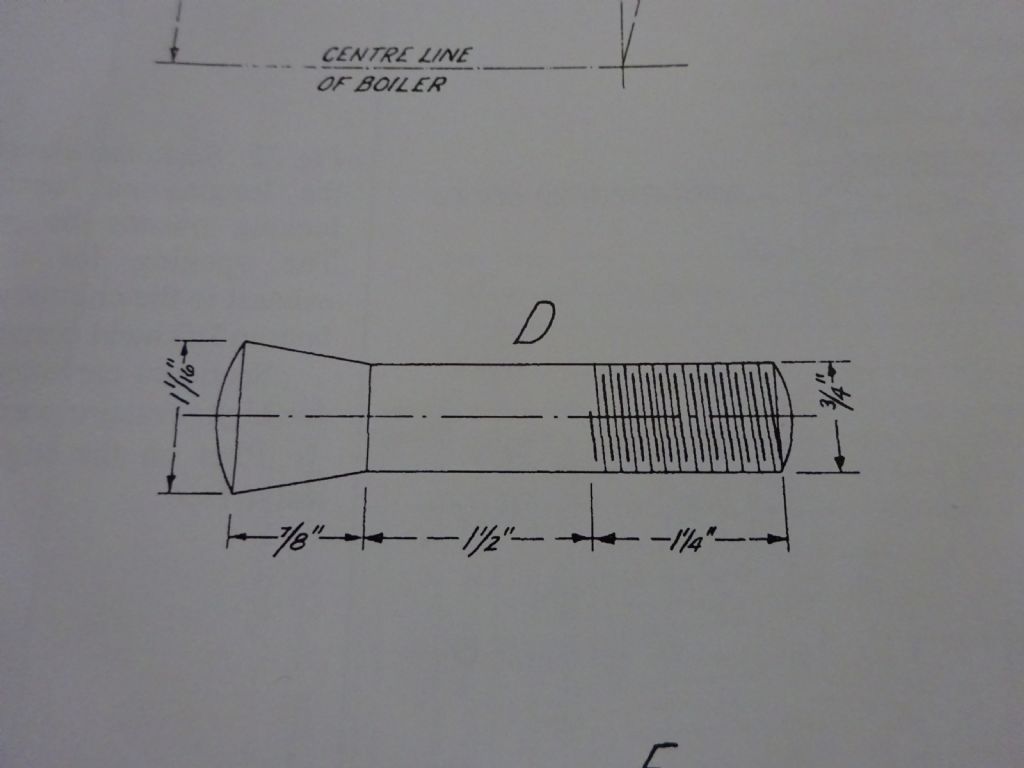

I'd like to say a few words about fitting these studs. They are made of bronze and I found them tricky to produce and fit. You need to take care about the exact length, they need to show one nut thickness plus one thread or so, with the cylinder and its sealing gasket in place, when tightly screwed in. The cylinder flange thickness may vary, depending on how the saddle was machined, mine did. There is not much length to grip the studs with, so you need to make a good stud driver to screw them tightly home against the end of the inner thread.I reduced this problem by fitting nuts with silver solder to all the studs except one row, thus making them into bolts. One row of studs can be put in before the cylinder is placed, this should be done with the stud driver, the cylinder is then located and the other stud holes can be carefully spotted through taking care about the angle. I had to drill the holes with a hand drill, aiming by eye, because I couldn't get the whole boiler, hornplates, cylinder etc under my machine drill. So I ended up not getting the angle accurate and having to draw over some of the holes in the flange to get the studs through.

And before doing any of this, the cylinder needs to be accurately located square to the crankshaft at the exactly correct distance and in good contact with the saddle pad.. I made a fixture which connected the cylinder squarely to a dummy shaft which could sit in the crankshaft bearings. So the hornplates and bearings have to be already in place.

Good luck!

Paul

Edited By Paul Horth on 28/05/2019 11:14:59

Paul Horth.