Well well Mel the Magnificent confounds his armchair grumps, Stand back from success

I was backward in forthcoming as I didnt have any suitable blanks and ordered from EB

the pix are turned cw cos i forgot to landscape my phone – as you do

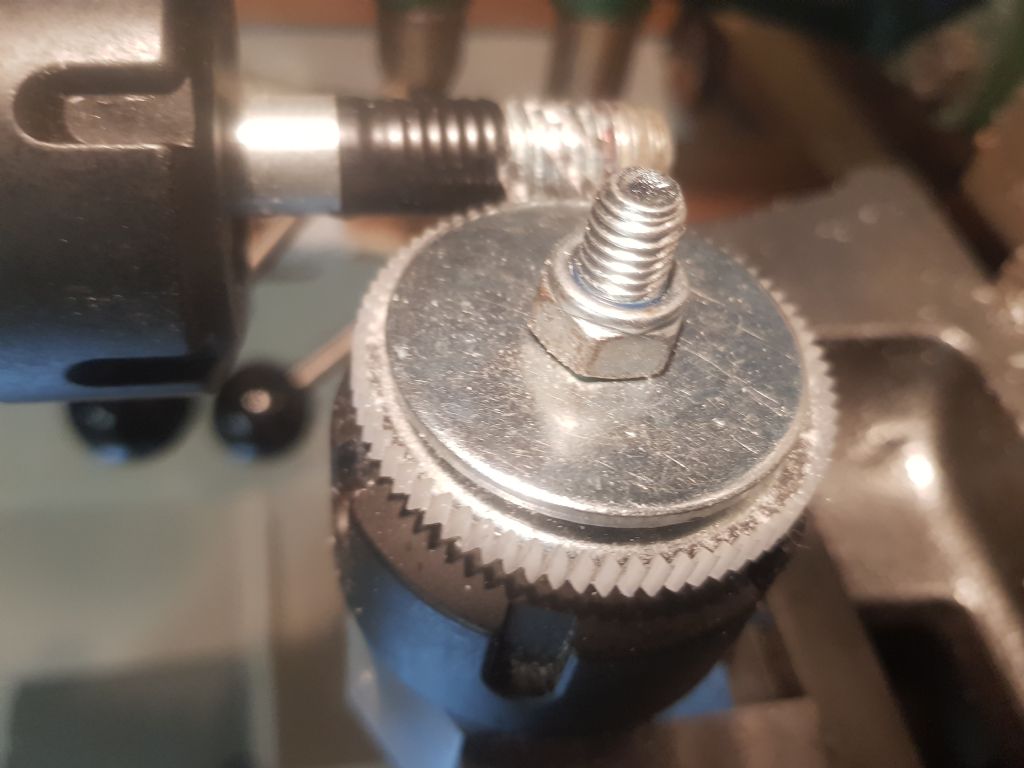

These are simple acrylic discs 6mm x 45mm gives circum = 141mm

i got 71 teeth

the bolt was 1/2" unc give 13 tpi – 1.954mm pitch so should give 72 teeth

so you get 1 less

Also note that my teeth are slightly slanted as I didnt bother with the helix angle just now

Note the crude bolt with the slits cut at 45deg, 6 in all to match the bolt head which i sliced off later. As a cutter it worked really well for what it was. I was very surprised. Even under a loup the teeth were respectable

I will have to try it in Aluminium and Brass before the naysayers go ape and spit the dummy

I will also try factoring the OD 71/72 x 45 = 44.37mm

Maybe try a slant of the blank to make a helix

I also located a pair of RH – LH threads might go for a herribone

I did make a video but I dont know yet how to put this on YT as per JB. Its so quiet and unhurried I shall add something symphonic

Edited By brian jones 11 on 13/09/2021 19:30:54

well I did manage a vid on YT

https://youtu.be/rcXPWMTVNig

its a lot easier than it used to be, i remember a daunting process which deterred me

Sorry no happy housewife muzak, this is my first YT attempt, lots of mistakes but I hope it shows the method

have ordered some al and br blanks and also the means for my herribone rude attempt. Who knows, will this lead to a rough hyperthyroid crown and pinion gear set. get your pooh sticks ready.

Edited By brian jones 11 on 13/09/2021 20:30:38

Martin Kyte.