Well this topic has certainly addled a few FES pates, like stirring up the suds sump

So to demystify the limits of plausible conjecture and give a platform to the deniably involved

What else on lockdown Sunday morning from the desk within my Anderson Shelter

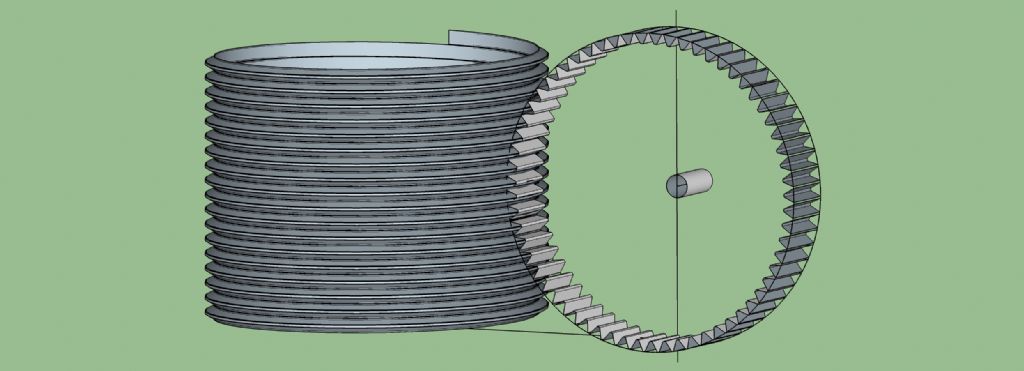

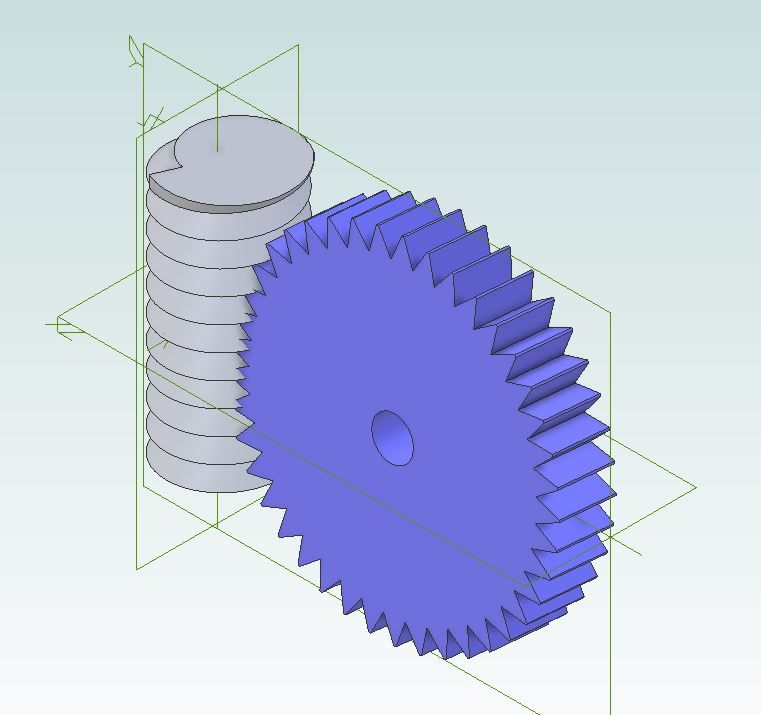

I hope you can see the double helix (truncated Whitworth form BTW). I skewed 6 deg for fun and made from 2 identical blanks chived at the same time

For the follically scarified, note that the yellow gear has been flipped over 180 to make the red

also if you skew one gear wrt the other fractionally then you can mitigate backlash

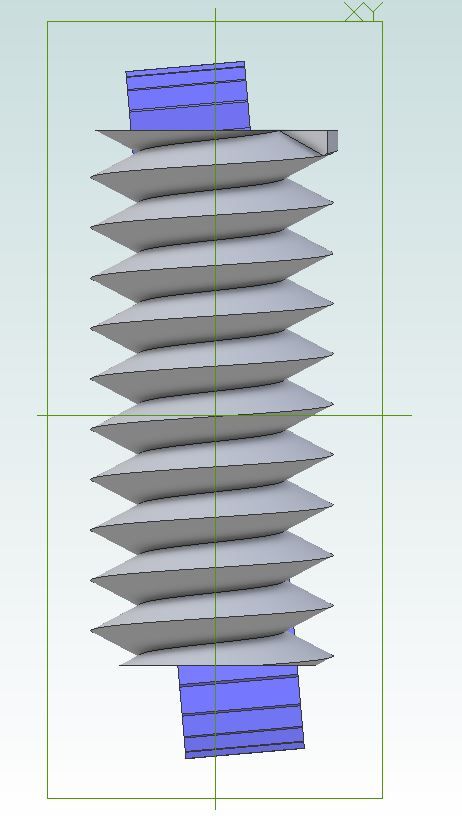

Now with the appliance of science I shall endeavour to make an animated version showing meshing and also the reviled tap attacking gear blanks

My biggest challenge will be to post mpg or gif on this board, I havent seen any other Disneys on here

Anyone know how its done – maybe Dropbox?, Ive never done a Youtube upload yet (do you have to sell your soul?)

Sorry JP missed your eminent description above, most interesting

As you point out, this OP is not about using hobbing gear and all the expensive industrial attachments involved, way off topic

The point being that a hobbing method ties the spindle mechanically to the mandrel in much the same way as screw cutting on a lathe (excluding the tedious divider plate method)

This is examining whether FREE HOBBING has a place for the hobbyist NPI. Its clearly demonstrated in making simple worm gears so this is just an extension of the topic. As seen above there are a lot of armchair misconceptions.

One point to note is that theoretical errors can creep in

eg

a) say you want to make a ruler with a 1" block. Use it to scribe 12 marks then do you have 1ft – well clearly it depends on the accuracy of the block. Hope you can see the implication of cumulative errors

b) Instead use the basic tech drawing trick use the block to make 12 ticks then project that onto a 1ft line and you have your accurate ruler with 12 inches

So the tap method is using method a) and the dividing plate (or hob) is using method b)

Now thats the theory but what happens in practice

Edited By brian jones 11 on 22/08/2021 12:44:19

Edited By brian jones 11 on 22/08/2021 12:46:01

Martin Kyte.