Duncan Webster helped me out last month by writing a program in Python3 to draw involute gears. (I was and still am struggling with the maths!) Duncan's code, which requires the easygraphics module, is here on Dropbox.

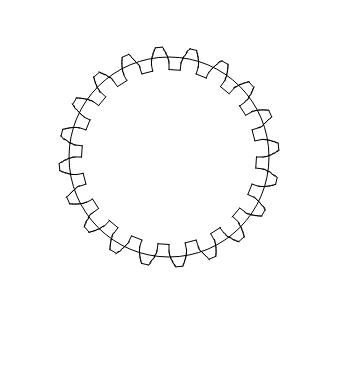

Duncan's teeth aren't drawn with curves, instead the involute is approximated by drawing a series of straight lines, i.e. facets. By default, the teeth are drawn with 12 facets, so a 20 tooth Mod 1 gear looks like this:

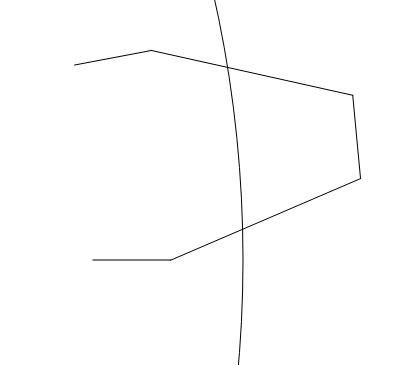

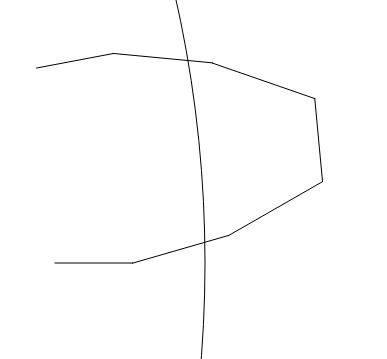

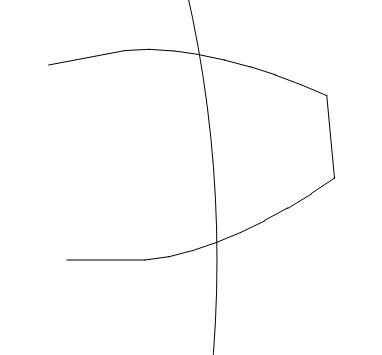

I bodged Duncan's code to draw only one tooth with 1,2,3,4 and 8 facets, all scaled up so the eye can see the facets.

Single facet teeth are obviously notchy:

Two facets are a considerable improvement:

Four facets are quite good:

And at this scale, eight facets are almost indistinguishable from a true curve.

All of these 'involutes' are approximations because of the way they are generated by drawing straight lines, but there are more issues to come.

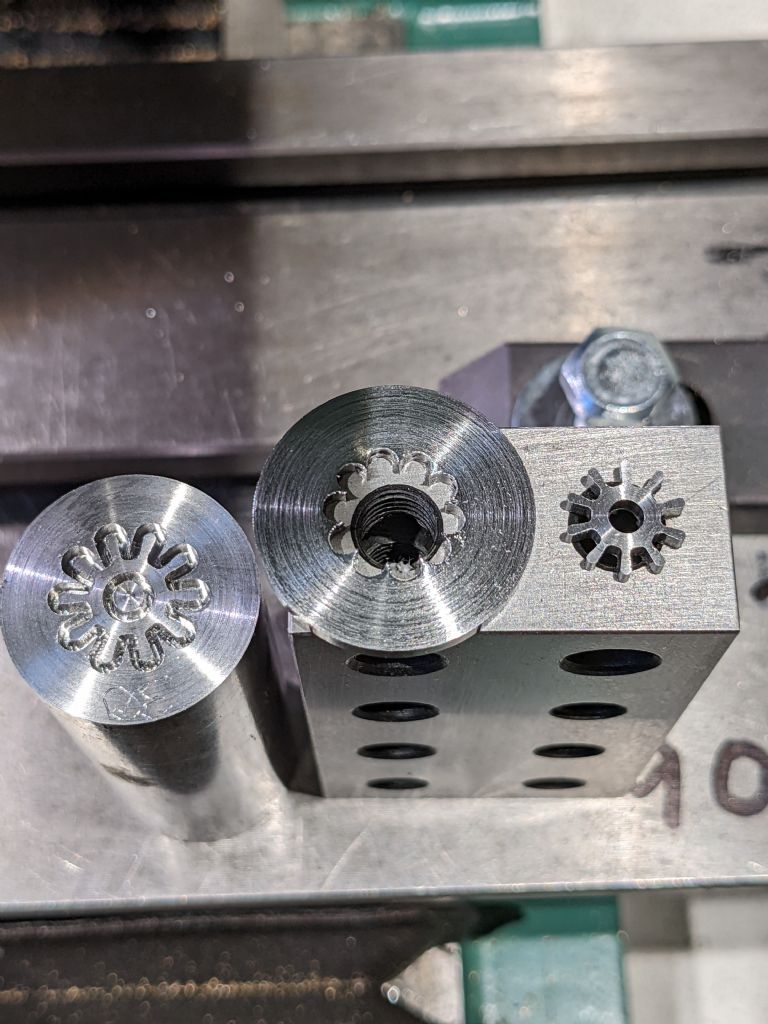

Duncan's program could be modified to produce G-code to make subtractive gears with a CNC mill or additive gears with a 3D printer. In both cases his mathematical involute could be an excellent approximation, say 24 facets or more, but the resulting gear will be degraded by the production process. Although both gears can be improved by cleaning up if necessary, the plastic and metal versions differ in strength while the metal version could also be greatly improved by polishing and hardening. The properties of a Duncan gear depend on the maths, the material, the basic production process, and the finishing. It's possible for Duncan gears to be either cheaply or better made as required. Most engineering objects are like this. They can be made up to an advanced specification or down to a price. Both useful, but don't waste money on uneccessarily expensive gear or on on cheap junk. It's the engineer's job to make cost effective choices.

My general point was lathe change-gears ain't anything special, and that it doesn't matter as long as they do the job.

Dave

Martin Kyte.