Posted by Dave S on 10/10/2021 18:24:04:

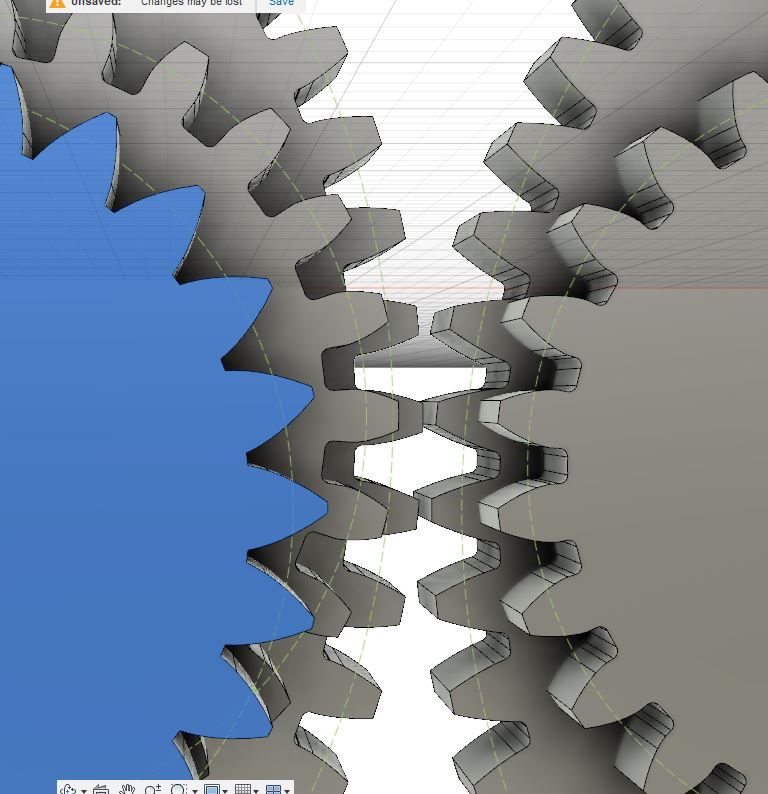

Hobbed gears have the same number of facets as the number of tooth gashes in the hob iirc.

So they are an approximation to the involute which usually have many facets.

Dave

Well the link doesn't agree with that statement Practical Machinist, I've extracted the important bit.

Quote:

Originally Posted by EPAIII

This is not really true. A hob has straight sides on it's teeth and therefore it cuts a series of flat facets for the gear tooth face. Thus the hob shown in post #9 has ten rows of teeth and will form a tooth with ten flats on each tooth face that approximate the involute curve. The more rows of teeth on the hob, the better the approximation. But it is not a "perfect" involute. It would take a hob with an infinite number of teeth to produce a perfect curve.

I don't know where you learned this, or whether you worked it out from first principles, but it's flat out wrong. I'm sorry to contradict you publicly and have no wish to cross swords, but it seems to me your post is just too misleading (and yet plausible and authoritative) to be left unchallenged on a fairly respected forum like this.

Hobbing is a generating process, which generates a true involute curve from a virtual straight sided 'rack' tooth form.

Provided it's set up in a hobbing configuration, correct involute teeth at any viable tooth count can be generated with a single tooth hob (ie a flycutter), if you have plenty of time to spare. Even in specialist gearcutting jobbing shops this is sometimes done for one-off tooth forms, for which the need is unlikely to recur.

Perhaps you're confusing hobbing with the hybrid sometimes adopted in home shops, using something which looks like a hob but with zero helix angle. Essentially it's like a stack of several form cutters, except the form is straight sided. The quasi-hob is disposed and traversed at right angles across the stationary workpiece (unlike a hob).

Martin Kyte.