I think Jasons Spin indexer (hereinafter to be known as Maureen's method) shows promise and needs more work ie mixing and matching her change wheels on a spin indexer

Cant quite get my head around the permutations maybe some lively mind can assist

here are Maureens std change wheel set

,20,21,28,30,32,33,35,39,40,43,45,48,50,51,53,55,57,60,63,64,65,70,72,75,80,81,85,90,95,100,127,,

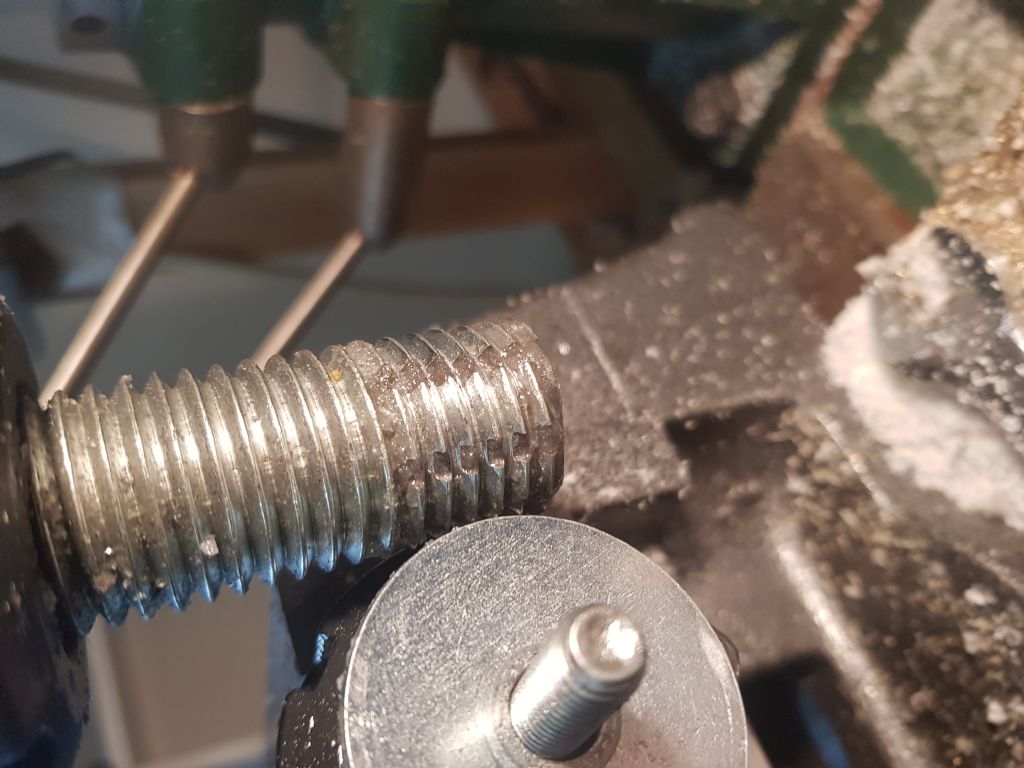

The paste up a paper printed dial is certainly promising when used with a junior hacksaw, you then only need a shaped cutter put into Arbor bench press like this for £10

https://www.ebay.co.uk/itm/124923302943?hash=item1d1602541f:g:IxkAAOSwdXlhUsLp

Now thats fair

OBTW you can only wind up Horologists

The Armchair Dragons in the Den are just waiting to see me fall over

but I have ordered an M24 HT bolt gr 8.8 (which I believe can be case hardened) together with a jig for my angle grinder then maybe get some sharp teeth into it

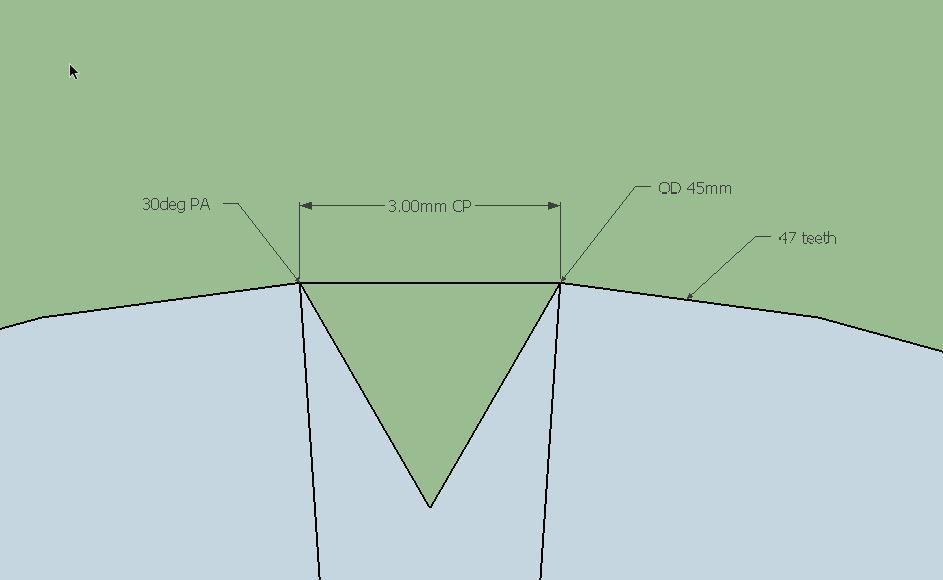

As for number of teeth prediction I have a polygon calculator in mind but need to back this up with some real models of the non ferrous kind. I found that WD40 also helped on perspex blanks. So you must bait your breath a while

Edited By brian jones 11 on 01/10/2021 05:40:59

Martin Kyte.